Super large power electromagnetic suction push-pull driving sound source

An electromagnetic suction, push-pull drive technology, applied in the field of acoustics, can solve the problems of impossible power, limited power, low radiation efficiency, etc., and achieve the effect of reducing nonlinear distortion, high energy conversion efficiency, and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

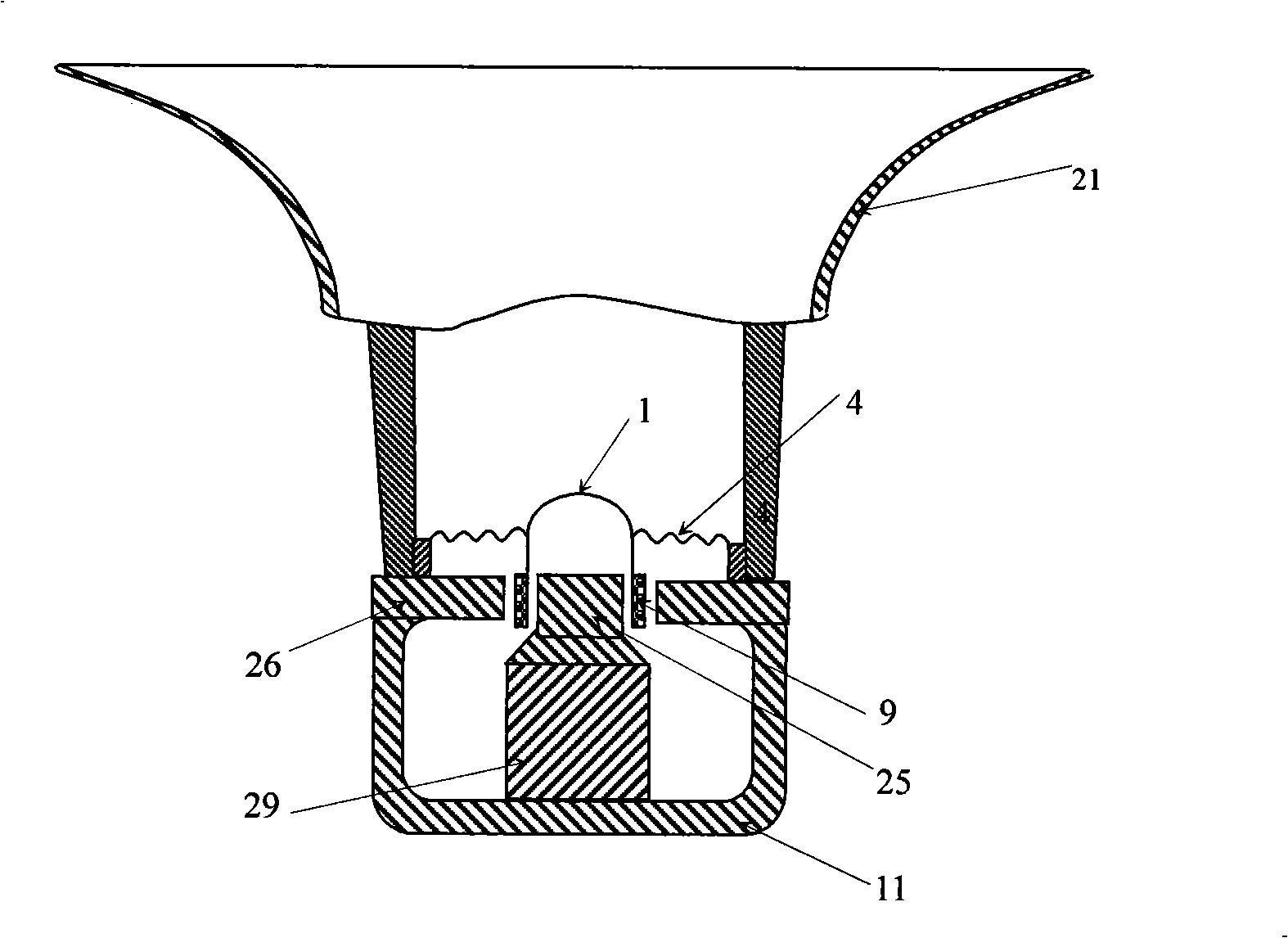

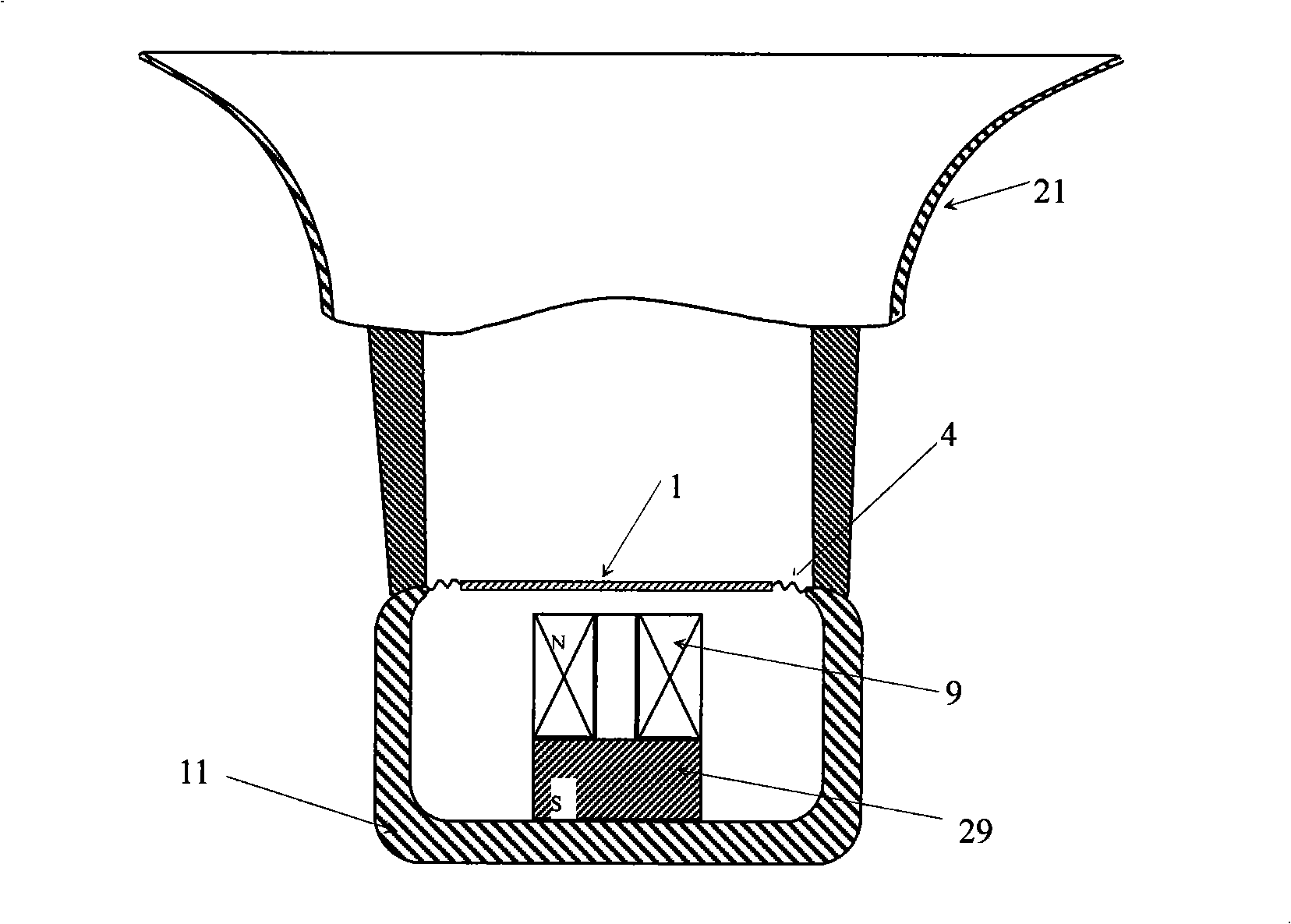

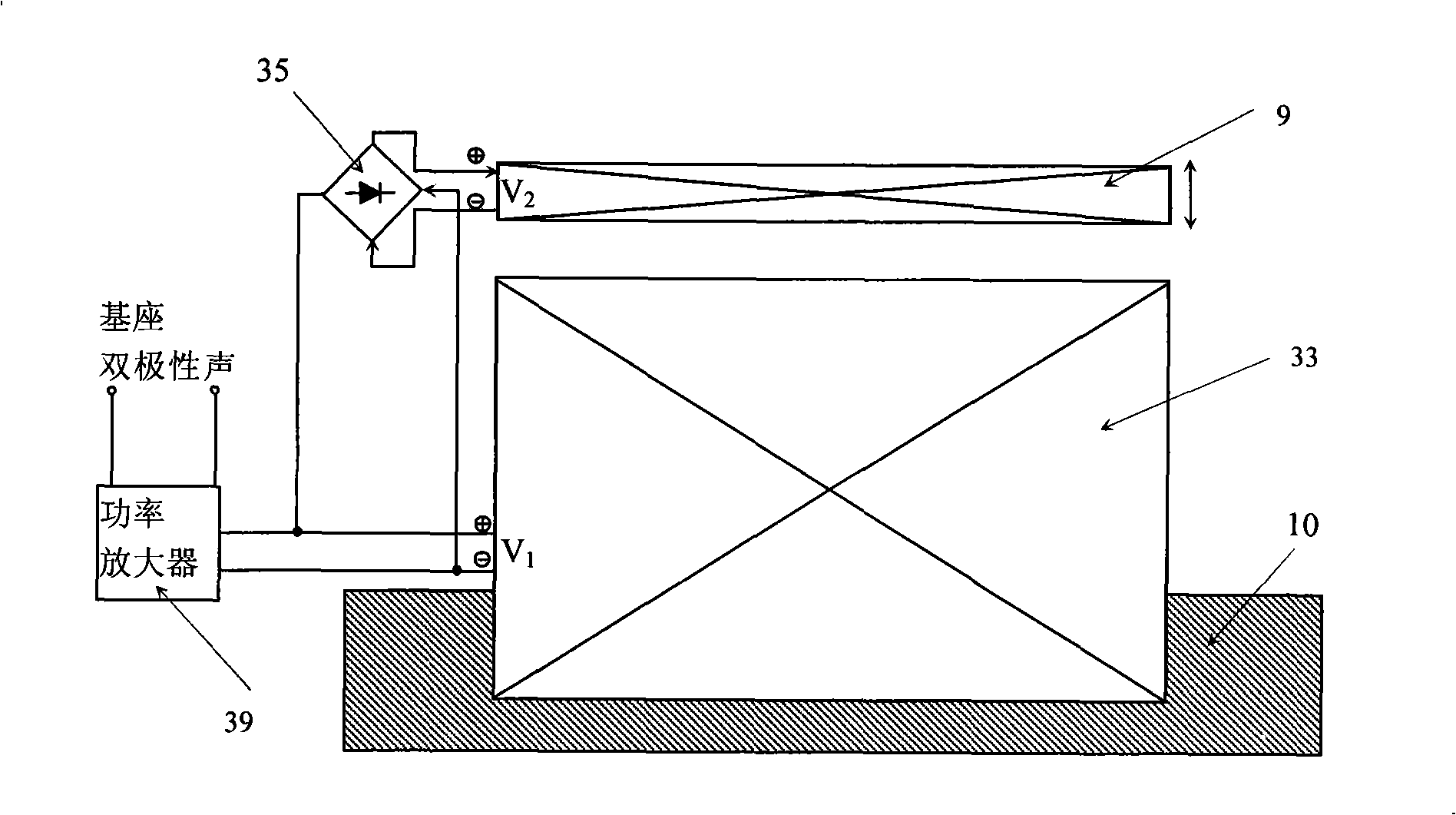

[0074] This embodiment is a push-pull driven electromagnetic suction loudspeaker with a single membrane and double bases, and its structure is as follows: Figure 4 , comprising, upper and lower base yokes 11, upper and lower center yokes 15, upper and lower coils 9, diaphragm 1, intermediate magnetic ring 13, ring 4, throat plug 22, sound outlet 20 and Speaker 21, and a control signal processing circuit.

[0075]In this embodiment, the central yoke 15 is tubular, and the pipeline is an acoustic radiation channel, using manganese-zinc intermediate frequency ferrite soft magnetic material, which has high magnetic permeability (>10000H / m), high resistivity (> 110Ωm), low specific gravity, low coercive force (<4.3A / m), and the working frequency can cover the audio frequency range. The upper and lower base yokes 11 are made of manganese-zinc intermediate frequency ferrite soft magnetic material, and the upper and lower center yokes 15 are mounted on the upper and lower base yokes...

Embodiment 2

[0088] The basic idea of this embodiment is consistent with that of Embodiment 1. In order to further improve the energy utilization rate, the present embodiment uses intermediate frequency silicon steel sheets to make the center yoke 15 and the base yoke 11 . The eddy current of the intermediate frequency silicon steel sheet is small, the magnetic permeability is high, and the insulation between the sheets forms a high resistivity to the eddy current. The use of silicon steel sheet can reduce the eddy current loss of audio current and improve the total energy utilization rate. The intermediate frequency silicon steel sheet can still only have a small eddy current at a frequency of about 15000Hz.

[0089] Such as Figure 12 As shown, this embodiment uses a "mountain"-shaped silicon steel sheet. During use, the silicon steel sheet needs to be pressed tightly and bonded with epoxy resin, and then fixed at a high temperature of 300°C. The magnetically conductive and non-orien...

Embodiment 3

[0097] This embodiment is an ultra-high-power underwater acoustic transducer driven by a double-coil base push-pull electromagnetic. Its basic concept is consistent with that of Embodiment 1. The difference from Embodiment 1 is that a sounding board is used instead of a horn as an acoustic radiator.

[0098] Such as Figure 14 As shown, the present embodiment uses a rigid drive rod 24 (which may also be a pipe or other form of connector) to lead the vibration of the diaphragm 1 to the outer layer, and under the outer sounding plate (ie, the vibration plate 23), rubber ( Promptly after water-seal rubber 28 watertight, need not use just formed the underwater sound transducer like the loudspeaker in the air.The underwater sound transducer of present embodiment, its amplitude is big, and power is big, and operating frequency band, Electric-acoustic conversion efficiency is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com