Lanthanum molybdate based solid electrolyte film material and preparation thereof

A solid electrolyte and lanthanum molybdate-based technology, which is applied in chemical instruments and methods, molybdenum compounds, rare earth metal compounds, etc., can solve the problems that lanthanum molybdate-based materials cannot be obtained, production costs are difficult to reduce, and the scope of application is restricted. Achieve the effect of tight combination, low production cost and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

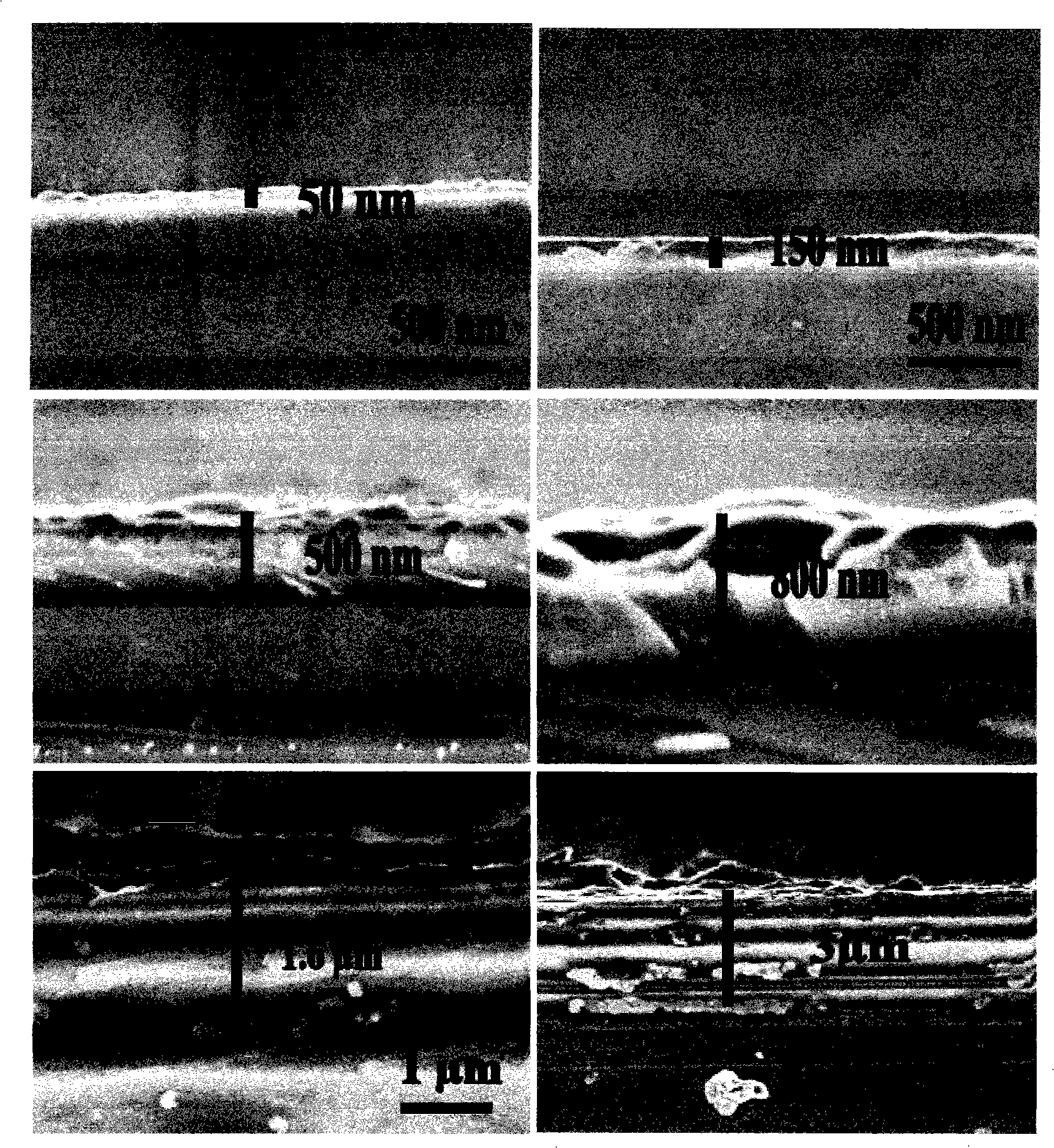

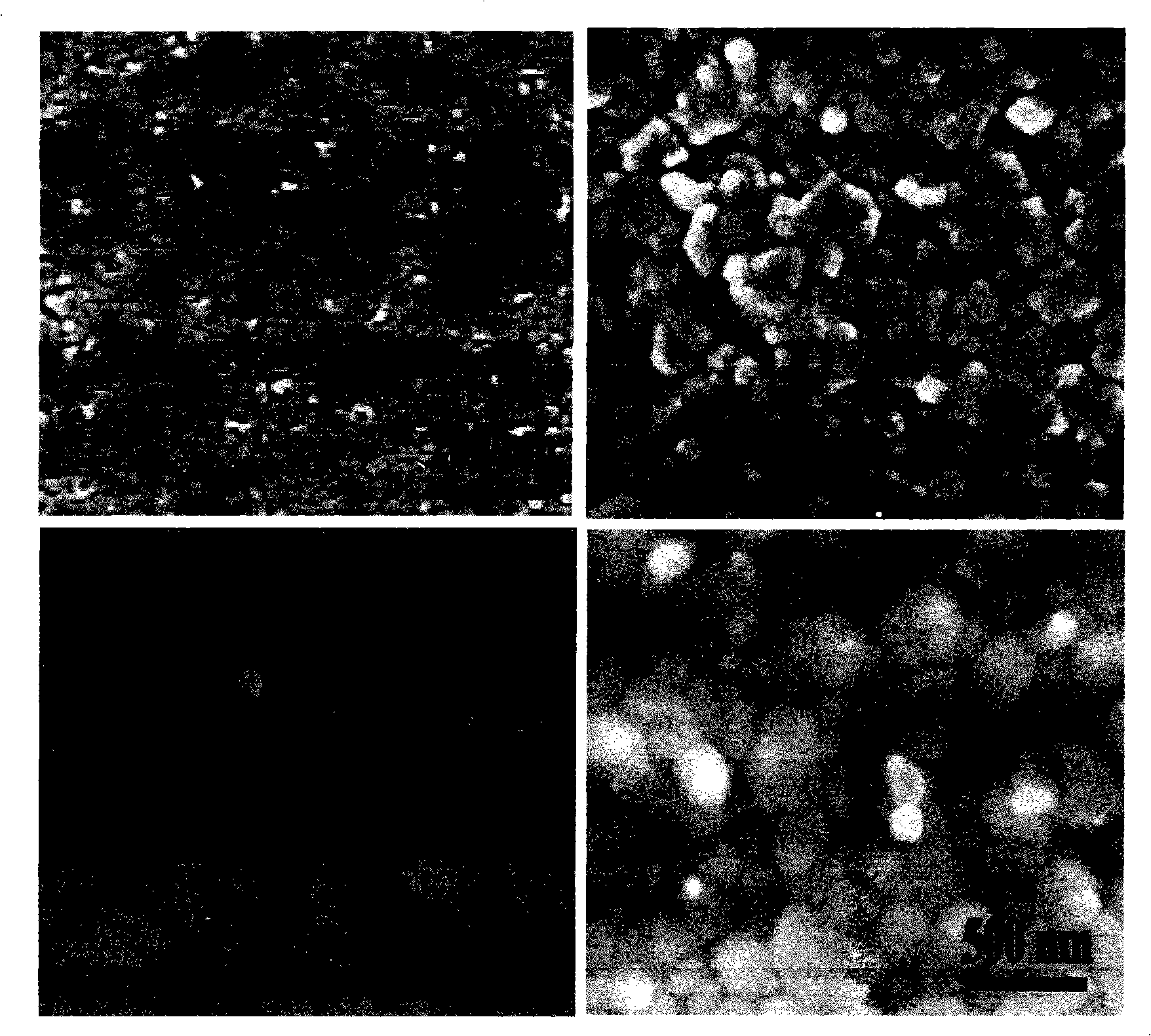

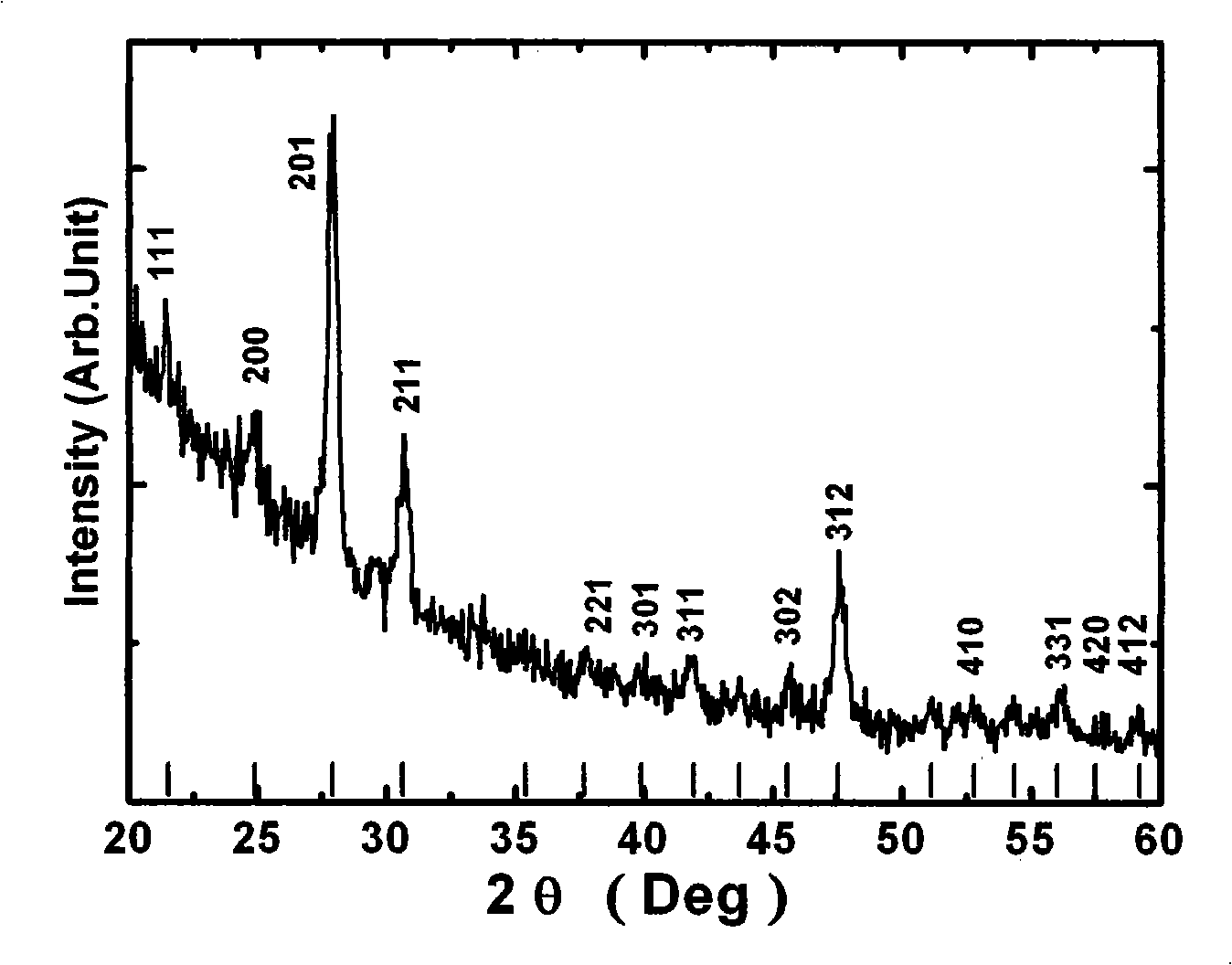

Embodiment 1

[0016]Embodiment 1: complete preparation successively according to the following steps: a) according to La 1.97 K 0.03 Mo 1.97 Fe 0.03 o 9-δ The composition ratio of the corresponding amount of lanthanum oxide, lanthanum dopant oxide or nitrate or acetate, ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 ] and the oxide or nitrate or acetate of molybdenum dopant, wherein the nitrate of lanthanum dopant is potassium nitrate, and the nitrate of molybdenum dopant is iron nitrate. Dissolve lanthanum oxide in nitric acid, and prepare the others into corresponding aqueous solutions, firstly dissolve lanthanum nitrate [La(NO 3 ) 3 ] solution was added dropwise to the ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 ] solution, and then add lanthanum dopant potassium nitrate solution and molybdenum dopant ferric nitrate solution to it to obtain a mixed solution. Next, citric acid was added to the mixed solution and then stirred, wherein the molar ratio of citric acid to the total metal ion...

Embodiment 2

[0017] Embodiment 2: complete preparation successively according to the following steps: a) according to La 1.97 K 0.03 Mo 1.97 Fe 0.03 o 9-δ The composition ratio of the corresponding amount of lanthanum oxide, lanthanum dopant oxide or nitrate or acetate, ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 ] and the oxide or nitrate or acetate of molybdenum dopant, wherein the nitrate of lanthanum dopant is potassium nitrate, and the nitrate of molybdenum dopant is iron nitrate. Dissolve lanthanum oxide in nitric acid, and prepare the others into corresponding aqueous solutions, firstly dissolve lanthanum nitrate [La(NO 3 ) 3 ] solution was added dropwise to the ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 ] solution, and then add lanthanum dopant potassium nitrate solution and molybdenum dopant ferric nitrate solution to it to obtain a mixed solution. Next, citric acid was added to the mixed solution and stirred, wherein the molar ratio of citric acid to the total metal ions in...

Embodiment 3

[0018] Embodiment 3: complete preparation successively according to the following steps: a) according to La 1.97 K 0.03 Mo 1.97 Fe 0.03 o 9-δ The composition ratio of the corresponding amount of lanthanum oxide, lanthanum dopant oxide or nitrate or acetate, ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 ] and the oxide or nitrate or acetate of molybdenum dopant, wherein the nitrate of lanthanum dopant is potassium nitrate, and the nitrate of molybdenum dopant is iron nitrate. Dissolve lanthanum oxide in nitric acid, and prepare the others into corresponding aqueous solutions, firstly dissolve lanthanum nitrate [La(NO 3 ) 3 ] solution was added dropwise to the ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 ] solution, and then add lanthanum dopant potassium nitrate solution and molybdenum dopant ferric nitrate solution to it to obtain a mixed solution. Next, citric acid was added to the mixed solution and then stirred, wherein the molar ratio of citric acid to the total metal io...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com