Solid fermentation substrate

A technology of solid fermentation and solid cultivation, which is applied in the direction of organic fertilizers, preparation of organic fertilizers, treatment of biological organic parts, etc., and can solve problems such as low microbial activity, long production cycle, and short duration of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

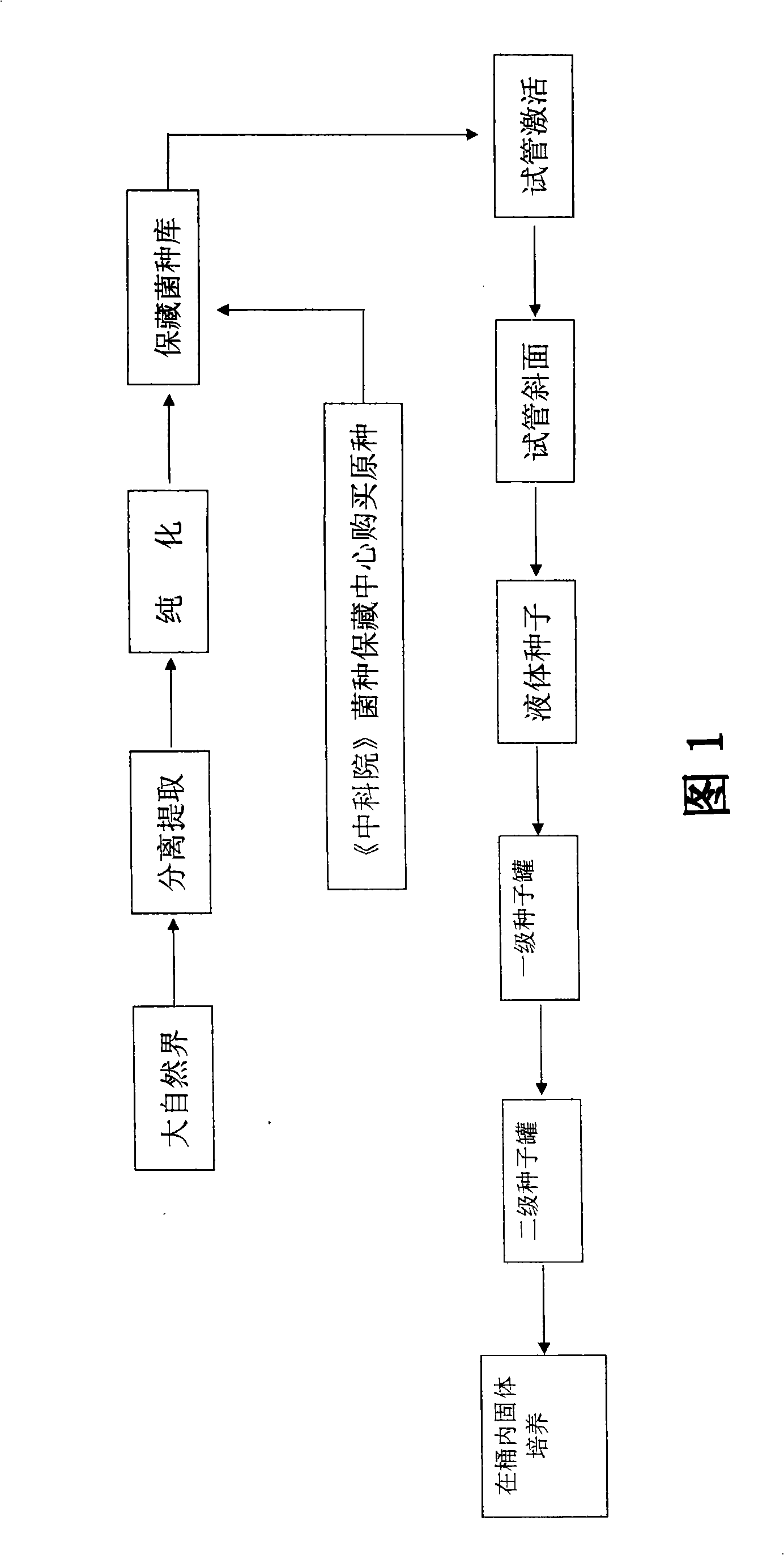

[0005] As shown in Figure 1, several bacterial agents of the described Erlenmeyer flask liquid culture and solid culture were dried in a sterile ventilated place. According to the ratio of bacterial species, (w / w) 32% of Bacillus subtilis, 22% of Bacillus licheniformis, 25% of Bacillus megaterium, 7% of Aspergillus oryzae and 14% of Amanita amanitae are mixed to form a solid fermentation base.

[0006] As shown in Figure 1, its production process is: ① Erlenmeyer flask liquid culture: put 200mL beef extract peptone liquid medium in a 500mL Erlenmeyer flask, after sterilization, inoculate Bacillus subtilis and Bacillus licheniformis in 2-ring inclined test tubes respectively , Bacillus megaterium, cultured on a shaker at 35°C for 48 hours to amplify; put 200mL potato sucrose liquid culture medium in a 500mL Erlenmeyer flask, after sterilization, inoculate Aspergillus oryzae and Pyreum arborii in 2-ring inclined test tubes respectively, Cultivate on a shaker at 28°C for 4 days t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com