Multi-stage phase change micro-nano complex fiber, and preparation method and application thereof

A composite fiber, micro-nano technology, applied in fiber processing, fiber chemical characteristics, melt spinning, etc., can solve the problems of low content of phase change materials, layered precipitation, liquid leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

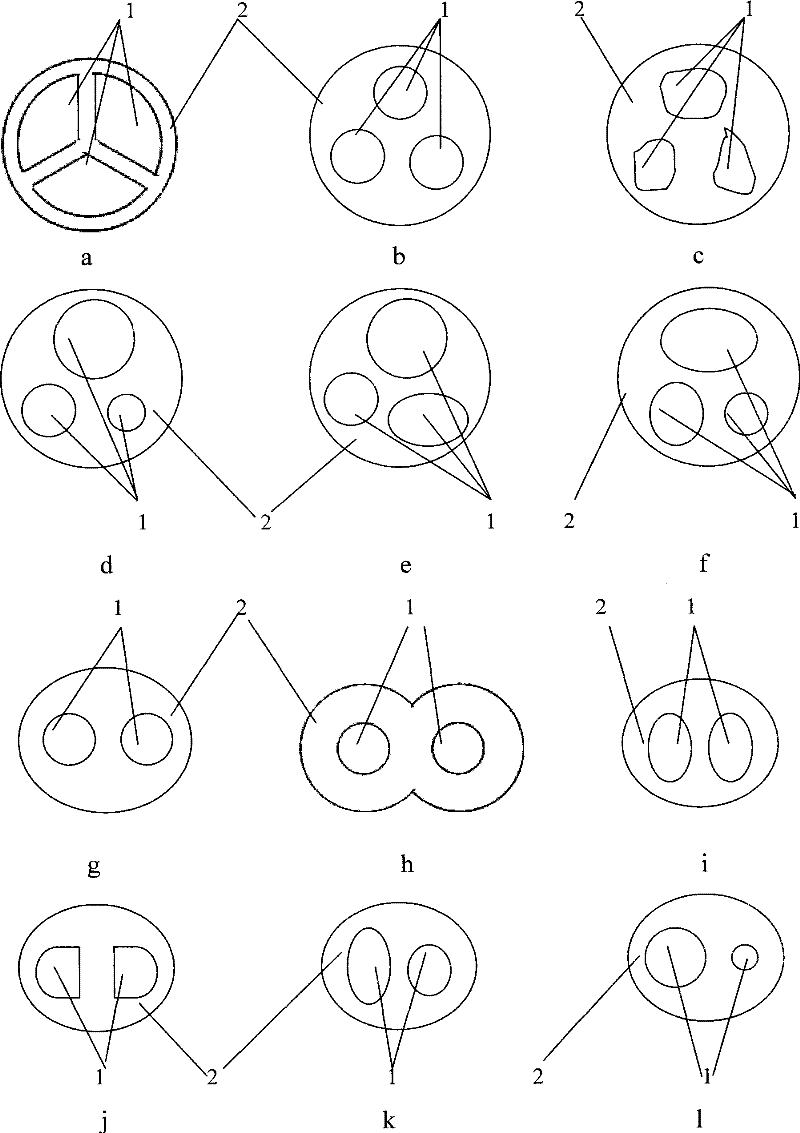

Method used

Image

Examples

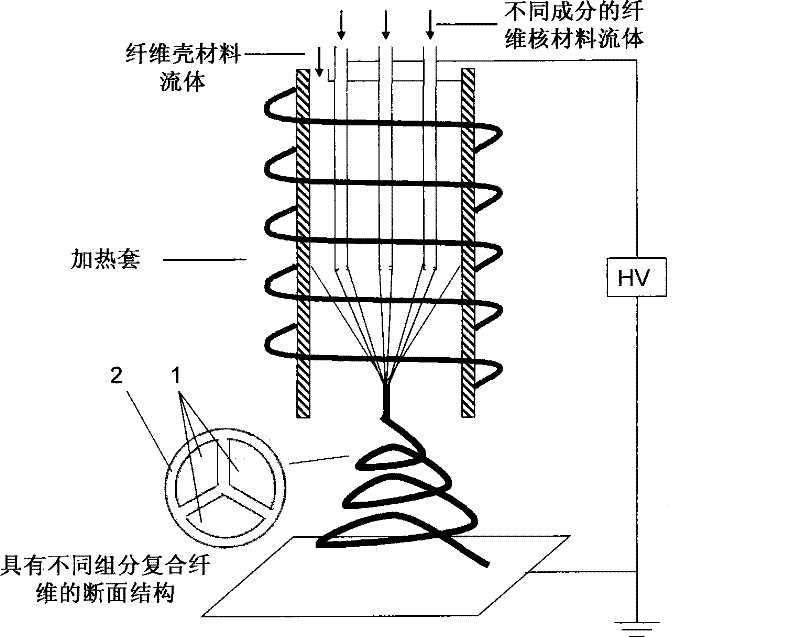

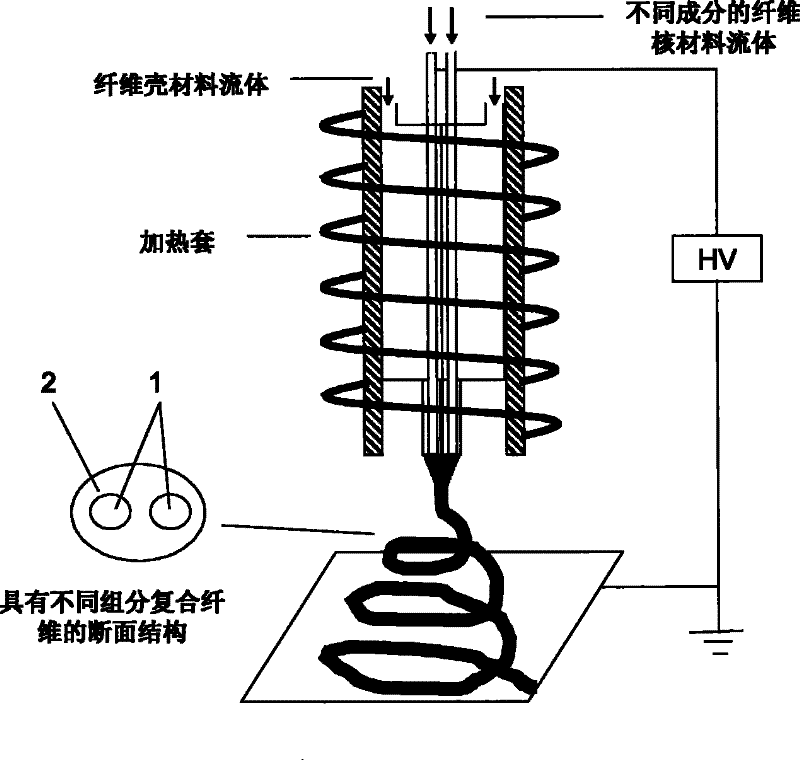

Embodiment 1

[0048] Take 0.3g PVP, 3g Ti(OBu) 4 , 2 mL of acetic acid, and 5 mL of ethanol were mixed as the shell solution, and n-hexadecane and n-octadecane were used as the core solution. Figure 2a The experimental setup (2 fluid channels inside) was used for spinning. The external ambient temperature is 25°C, the relative humidity is 50%, the electrospinning voltage is 25-30KV, the distance between the spinneret and the collecting plate is 30cm, and n-hexadecane and n-octadecane are simultaneously injected into the two inner fluid (nuclear material) channels , the flow rate of the core solution is 1mL / h, the flow rate of the shell solution is 8-10mL / h, and the prepared fibers are collected with a collecting plate.

[0049] The outer diameter of the prepared fibers is 2-5 μm. Differential thermal analysis (DSC) results show that the phase transition melting temperature peaks of this phase change energy storage fiber are 17 °C and 28 °C, reflecting the nature of multi-stage phase tran...

Embodiment 2

[0051] Take 2g PVP, 6g Ti(OiPr) 4 , 2 mL of acetic acid, and 10 mL of ethanol were mixed as the shell layer solution, and n-hexadecane, n-docosane, and n-triacontane were used as the core layer solution. Figure 2a The experimental setup for spinning. The external ambient temperature is 28°C, the relative humidity is 40%, the electrospinning voltage is 20-25KV, the distance between the spinneret and the collecting plate is 20cm, and n-hexadecane and n-20 are respectively injected into the three inner fluid (nuclear material) channels. Dioxane, n-triacontane, the flow rate of the core solution is 1.5mL / h, and the flow rate of the shell solution is 5-8mL / h, and the prepared fibers are collected with a collecting plate.

[0052] The outer diameter of the prepared fibers is 0.5-4 μm. The results of differential thermal analysis show that the phase change fiber has melting phase transition peaks at 17℃, 44℃ and 68℃, indicating that the fiber has the property of multi-stage phase ...

Embodiment 3

[0054] Take 0.1molNiAc 2 ·4H 2 O was dissolved in 1 mol absolute ethanol, then 0.1 mol HNO was added 3 Stir and add 0.1mol Ti(OiPr) after a few hours 4 , stirring for 5 hours. A DMF solution with a concentration of 14 wt% PVAc was added and stirred uniformly. NiTiO 3 The mass ratio of sol to PVAc solution was 0.7:1. The prepared sol is used as the shell layer solution, and deca alcohol, dodecanol, hexadecanol, and eicosanol are used as the core layer solution. Figure 2a The experimental setup for spinning (4 inner fluid channels). The external environment is 25°C, the relative humidity is 70%, the electrospinning voltage is 10-15KV, the distance between the spinneret and the collecting plate is 15cm, and ten alcohol, dodecanol, hexadecanol and Eicosanol, the flow rate of the core solution is 0.7mL / h, and the flow rate of the shell solution is 1-5mL / h, and the prepared fibers are collected with a collecting plate.

[0055]The outer diameter of the prepared fibers is 3-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com