One-dimensional nano-array zinc oxide solid-phase micro-extraction coating and preparation method thereof

A nano-array and zinc oxide technology, which is applied in the interdisciplinary field of analytical chemistry and material science, can solve the problems of undeveloped and underutilized coatings, achieve good thermal stability and surface uniformity, improve extraction capacity and extraction efficiency Selective and operable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

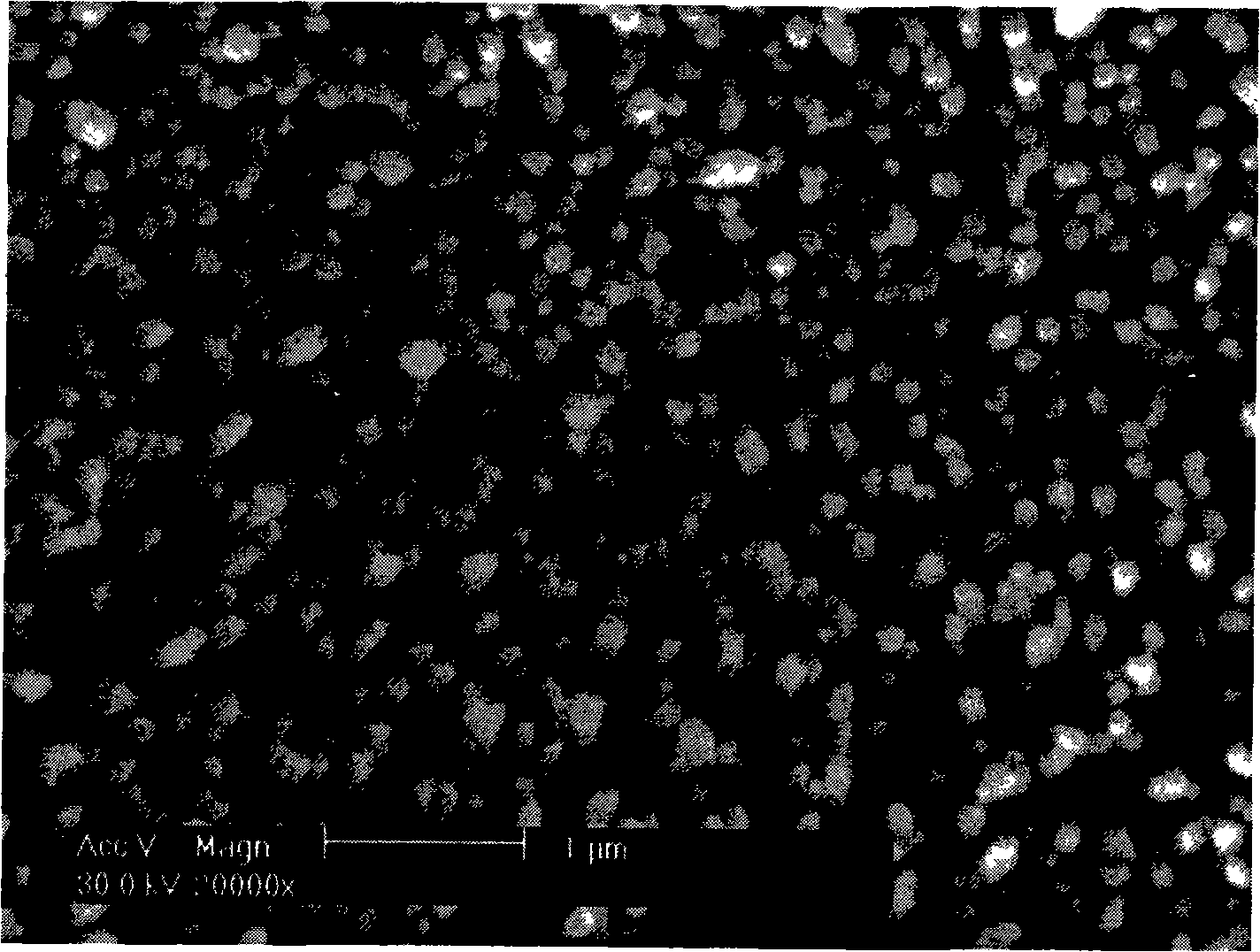

Image

Examples

Embodiment

[0017] Quartz fiber pretreatment: quartz fiber with a protective layer on the outside → soak in acetone for 10 minutes and peel off the outer protective layer by 2 cm → wash with a large amount of distilled water → ethanol ultrasonic vibration for 5 minutes to remove oil;

[0018] Crystal nucleus formation: The pretreated quartz fiber is soaked in an equimolar mixture of 0.5mol / L zinc acetate and 0.5mol / L hexamethylenetetramine for 5 minutes, and then baked in an oven at 190°C for 10 minutes; this process Repeat 5 times respectively;

[0019] Hydrothermal reaction: prepare 0.05mol / L zinc acetate and 0.05mol / L hexamethylenetetraammonium solutions respectively, mix the two evenly in equal volumes, pour the solutions into the reaction kettle, and then pour the quenched quartz Put the fiber into the reaction kettle and fix it to make it stand upright. Finally, put the reaction kettle into a drying oven at 110°C for 2 hours, then take it out and leave it overnight;

[0020] Drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com