Acid washing iron red desilication filter cake treating device and treating method

A processing device and filter cake technology, which is applied in the field of pickling iron red desiliconization filter cake processing device, can solve the problems of underground water source pollution, high chlorine content, non-recycling, etc., and achieve low investment, simple operation and maintenance, and remarkable technology progressive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

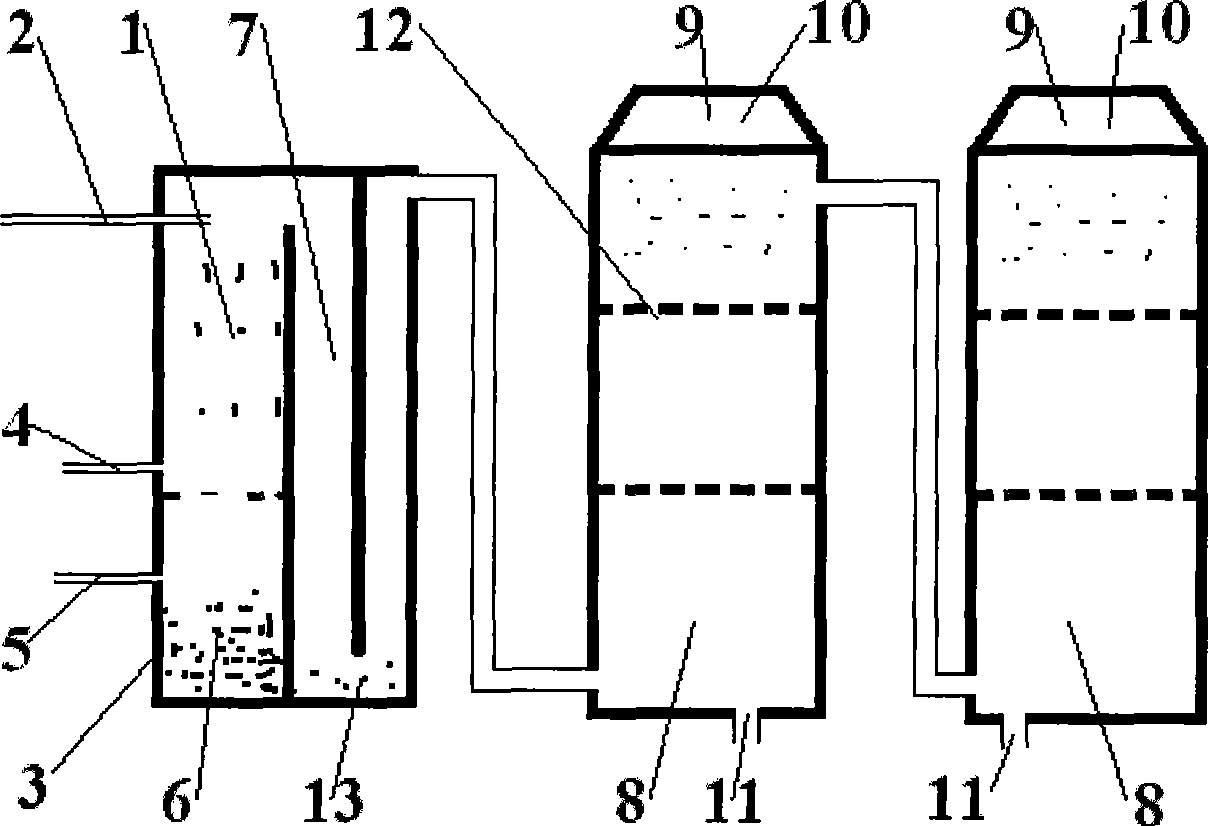

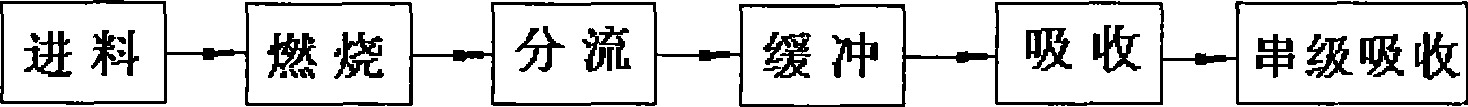

[0047] Embodiment 1. The structure of the heating device.

[0048] Described heating device is roasting tower 3, is provided with burner 4, is made of roasting tower 3 inner chambers, is provided with the feeder 2 that provides bulk filter cake 1 in burner 4 in its top, in burner 4 Below, the gas air inlet pipe 5 is set to communicate with the burner 4, and below the gas air inlet pipe 5, the inside of the roasting tower 3 is an iron oxide powder collection chamber 6.

[0049] The roasting tower 3 is the main equipment of the pickling iron red desiliconization filter cake treatment device, which provides a high-temperature zone for thermal decomposition of the filter cake 1. The maximum temperature in the high-temperature zone reaches 7500C, and it burns in an oxidizing atmosphere, and heats and decomposes iron chlorides. Under oxygen conditions, iron oxides are obtained; chloride ions are hydrolyzed at high temperature to generate hydrogen chloride gas.

[0050] The iron oxi...

Embodiment 2

[0052] Embodiment two, recovery device structure.

[0053] The recovery device is provided with a buffer tower 7 and an absorption tower 8, wherein the buffer tower 7 is connected with the roasting tower 3 as a whole, and the passage inside the buffer tower 7 is a "U" shape connected to the bottom, and one of the "U" The upper end communicates with the burner 4, and the other upper end communicates with the lower part of the absorption tower 8 through a pipeline.

[0054] The mixed gas entering the buffer tower 7 from the roasting tower 3 enters the buffer tower 7 in a downstream manner, and the mixed iron oxide particles settle in the iron oxide particle sedimentation tank 13 at the bottom of the buffer tower 7, which has the function of dust removal and can be recovered. It has the function of purifying and cooling the mixed gas. Make the temperature of the mixed gas entering the absorption tower 8 no more than 110°C, and use silicon refractory material inside, which can re...

Embodiment 3

[0055] Embodiment 3, absorption tower structure.

[0056] A sprinkler 9 is arranged on the top of the absorption tower 8, and is connected with a water source of industrial pure water 10 through pipelines; an industrial hydrochloric acid recovery port 11 is arranged at the bottom thereof. The industrial hydrochloric acid recovery port 11 is connected with the acid tank of the strip pickling process, and the recovered industrial hydrochloric acid flows to the acid tank of the pickling process for recycling and reuse.

[0057] There are multiple sets of absorption towers 8, which are used in cascade. The industrial pure water 10 can also be used in countercurrent cascade to ensure the absorption effect. The absorption tower 8 is equipped with a perforated drain plate 12, and the inside of the tower is slightly negative pressure to improve the absorption effect. . The main tower body materials are polypropylene, polytetrafluoroethylene and enamel products. Currently, there are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com