Lanthanum molybdate-based nanotube array and preparation thereof

A nanotube array and lanthanum molybdate technology, applied in the field of nanotube arrays and manufacturing methods, can solve the problems of energy consumption, complicated preparation process, difficult to reduce production cost, etc., and achieve high conversion efficiency, high ionic conductivity, and total electrical conductivity. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

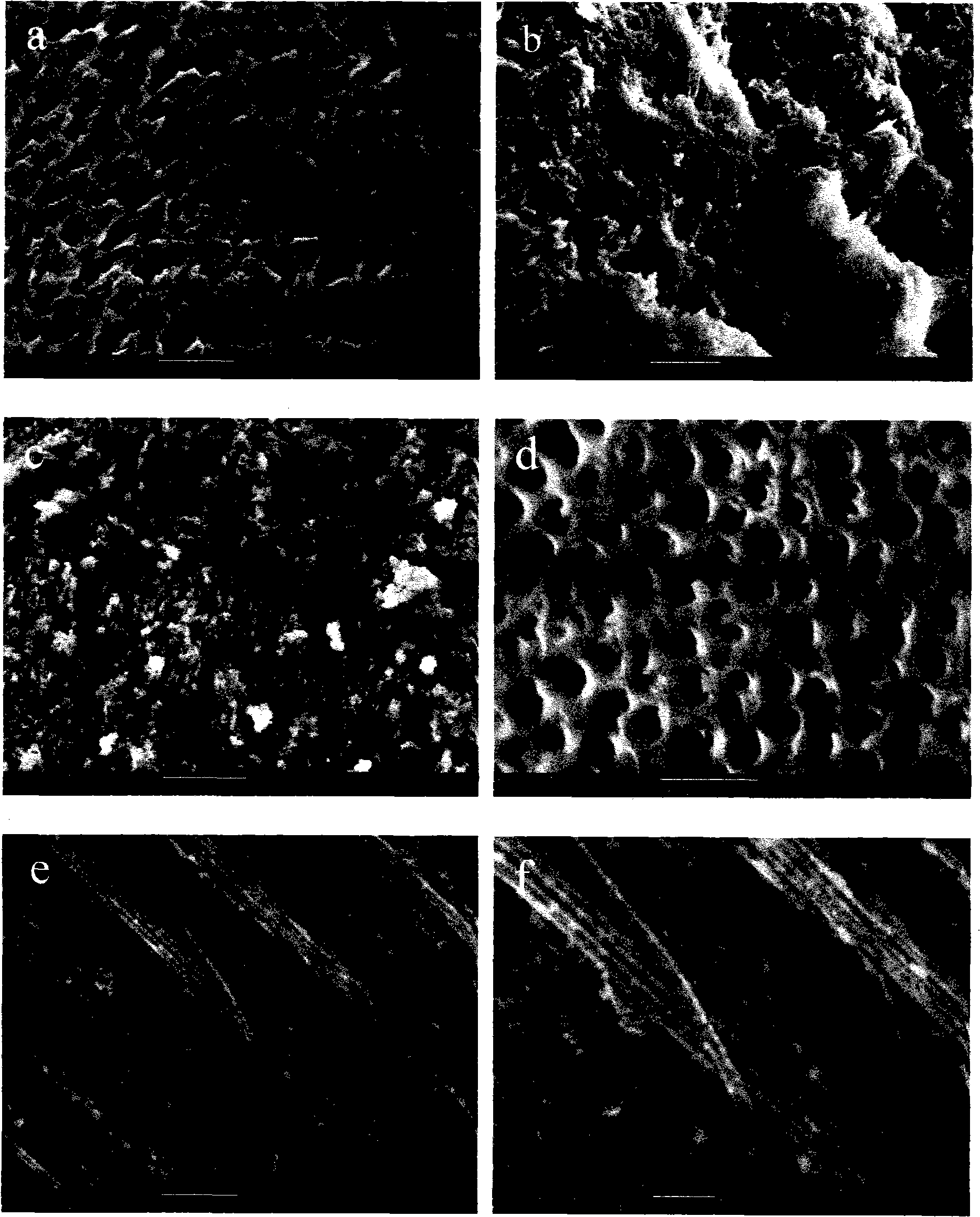

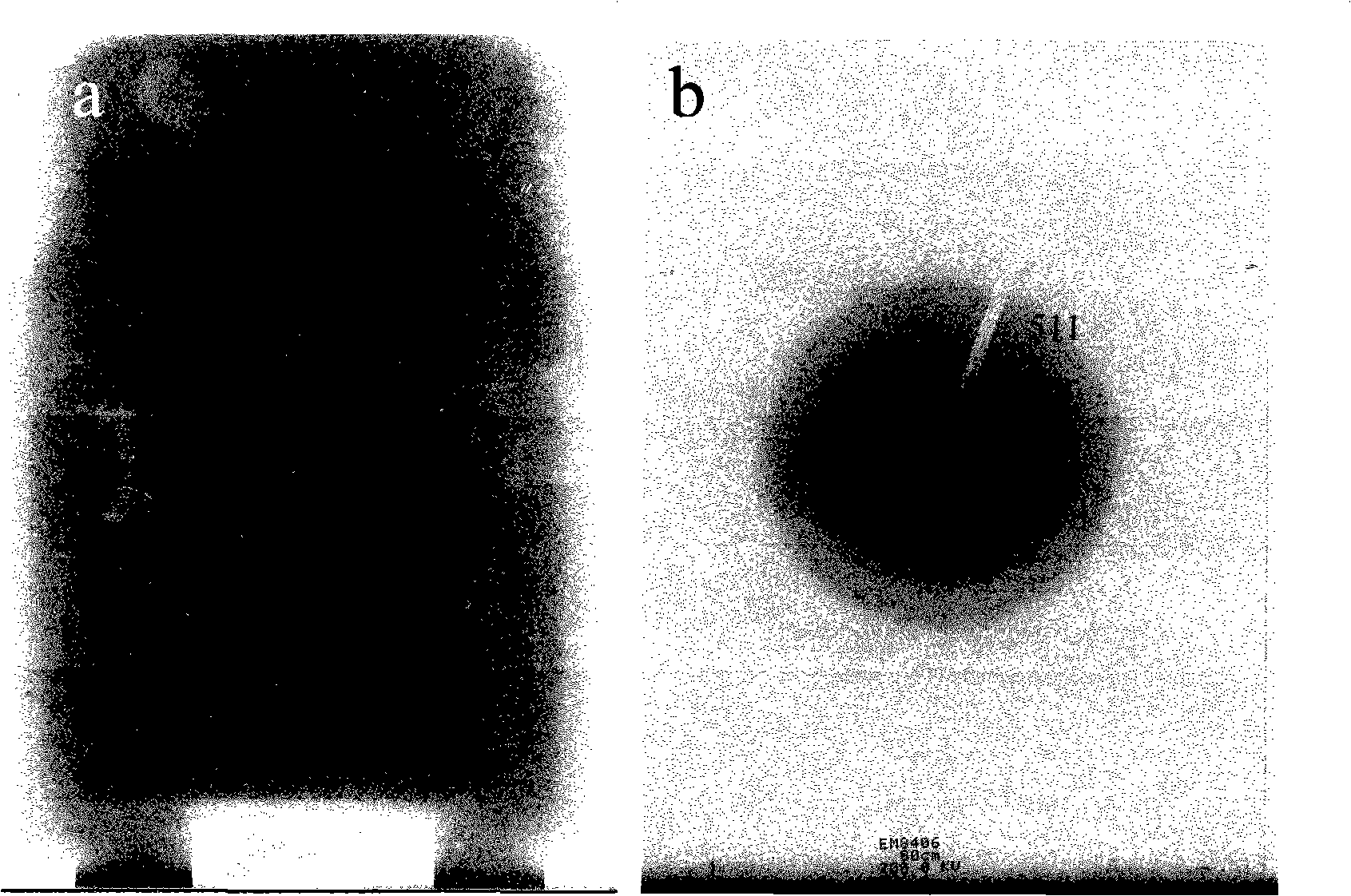

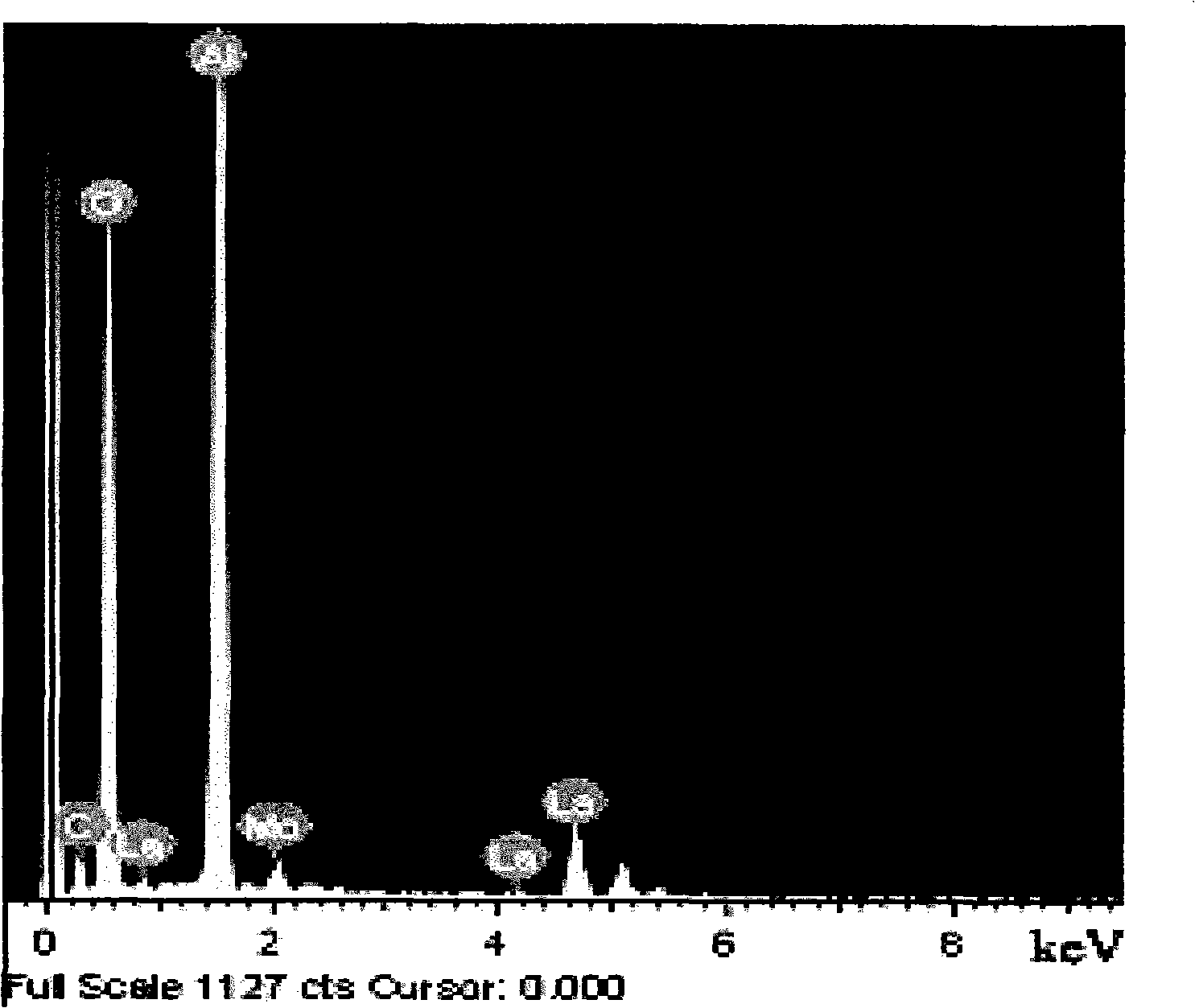

Embodiment 1

[0017] Embodiment 1: complete preparation successively according to the following steps: a) according to La 1.97 K 0.03 Mo 1.97 Fe 0.03 o 9-δ The composition ratio of the corresponding amount of lanthanum oxide, lanthanum dopant oxide or nitrate or acetate, ammonium molybdate and molybdenum dopant oxide or nitrate or acetate, wherein, The nitrate of the lanthanum dopant is potassium nitrate, and the nitrate of the molybdenum dopant is iron nitrate (the value range of the lanthanum dopant and the molybdenum dopant in the chemical formula can be between 0 and 2 choose). Lanthanum oxide, potassium nitrate, ammonium molybdate and ferric nitrate are respectively added into a solvent to prepare a corresponding solution, wherein the solvent is ethylene glycol, and the amount used is constant. First add nitric acid to the lanthanum oxide solution to dissolve it into lanthanum nitrate, then add the lanthanum nitrate solution dropwise into the stirred ammonium molybdate solution, a...

Embodiment 2

[0018] Embodiment 2: complete preparation successively according to the following steps: a) according to La 1.97 K 0.03 Mo 1.97 Fe 0.03 o 9-δ The composition ratio of the corresponding amount of lanthanum oxide, lanthanum dopant oxide or nitrate or acetate, ammonium molybdate and molybdenum dopant oxide or nitrate or acetate, wherein, The nitrate of the lanthanum dopant is potassium nitrate, and the nitrate of the molybdenum dopant is iron nitrate (the value range of the lanthanum dopant and the molybdenum dopant in the chemical formula can be between 0 and 2 choose). Lanthanum oxide, potassium nitrate, ammonium molybdate and ferric nitrate are respectively added into a solvent to prepare a corresponding solution, wherein the solvent is ethylene glycol, and the amount used is constant. First add nitric acid to the lanthanum oxide solution to dissolve it into lanthanum nitrate, then add the lanthanum nitrate solution dropwise into the stirred ammonium molybdate solution, a...

Embodiment 3

[0019] Embodiment 3: complete preparation successively according to the following steps: a) according to La 1.97 K 0.03 Mo 1.97 Fe 0.03 o 9-δ The composition ratio of the corresponding amount of lanthanum oxide, lanthanum dopant oxide or nitrate or acetate, ammonium molybdate and molybdenum dopant oxide or nitrate or acetate, wherein, The nitrate of the lanthanum dopant is potassium nitrate, and the nitrate of the molybdenum dopant is iron nitrate (the value range of the lanthanum dopant and the molybdenum dopant in the chemical formula can be between 0 and 2 choose). Lanthanum oxide, potassium nitrate, ammonium molybdate and ferric nitrate are respectively added into a solvent to prepare a corresponding solution, wherein the solvent is ethylene glycol, and the amount used is constant. First add nitric acid to the lanthanum oxide solution to dissolve it into lanthanum nitrate, then add the lanthanum nitrate solution dropwise into the stirred ammonium molybdate solution, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com