Method for removing sulfur in diesel by photo catalytic oxidation

A photocatalytic oxidation, gasoline and diesel technology, applied in the direction of refining with oxygenated compounds, etc., can solve the problems of no oxidation effect of thiophene, loss of organic components, and low oxidation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

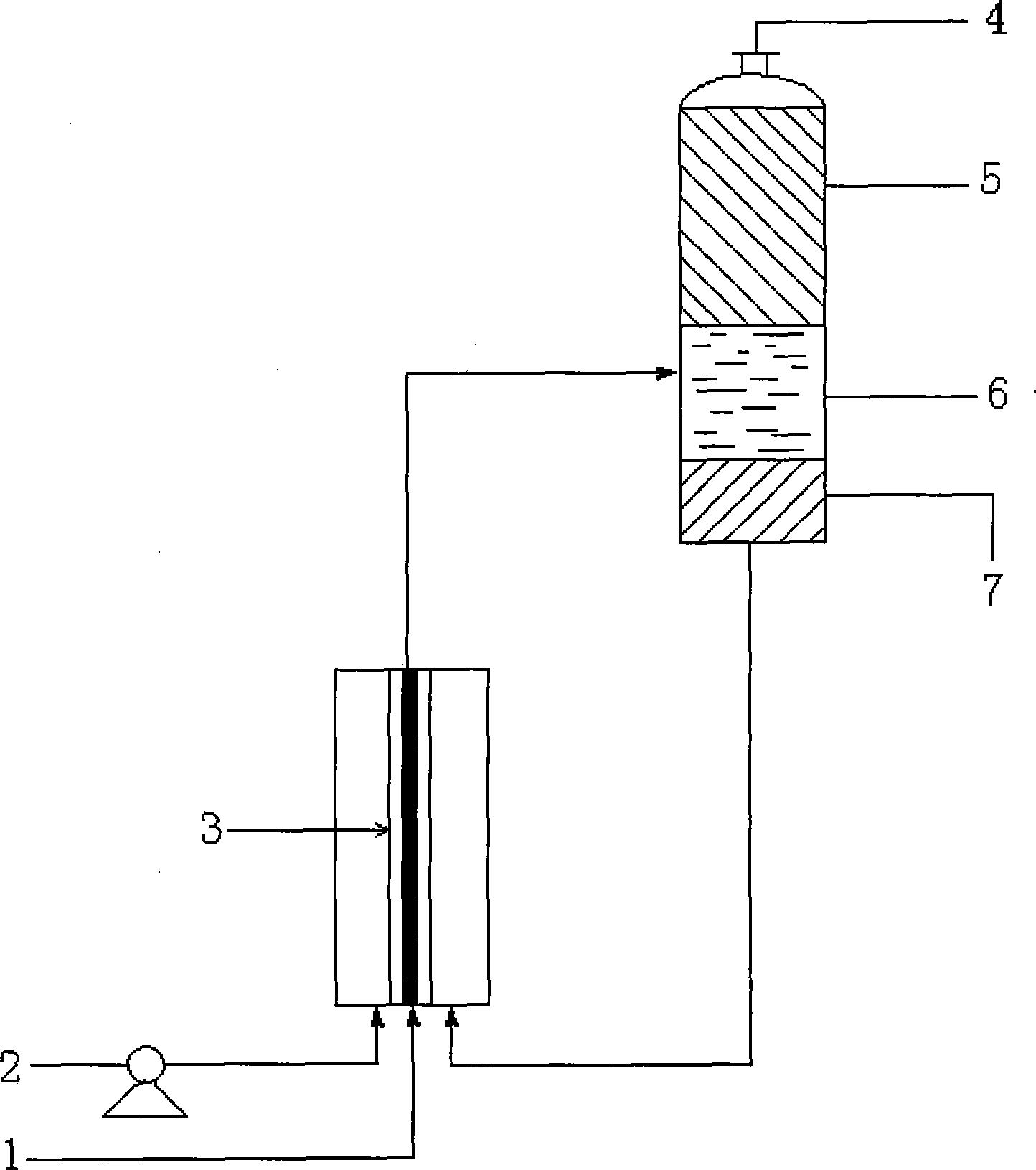

Method used

Image

Examples

Embodiment 1

[0023] Add 1 milliliter of acetonitrile and 2 milligrams of phosphotungstic acid respectively in 3 30 milliliters glass reactors, then add three kinds of different sulfur content gasolines respectively (the sulfur content is respectively

[0024] 72mg / l, 80mg / l, 102mg / l) 9ml each, mix well, seal, and pass through O 2 , O 2 Pressure is 0.08MPa, stirring, turn on xenon lamp (500W), carry out ultraviolet light irradiation, stop reaction after 10 hours, gasoline sulfur removal rate is respectively 45%, 65% and 75%. For the desulfurization effect of the photocatalytic system on the actual samples of the three types of gasoline and the comparison of the control tests, see Figure 5.

Embodiment 2

[0026] Add 1 ml of ethanol and 2 mg of sodium phosphotungstate into a 30 ml glass reactor, then add 9 ml of gasoline with a sulfur content of 80 mg / l, mix well, seal it, and pour O 2 , O 2 Pressure is 0.05MPa, stir, turn on high-pressure mercury lamp (200W), carry out ultraviolet light irradiation, stop reaction after 10 hours, gasoline sulfur removal rate is respectively 35%.

Embodiment 3

[0028]Add 1 milliliter of methanol and 2 milligrams of phosphomolybdic acid to three 30 milliliter glass reactors respectively, and then add three types of gasoline with different sulfur content (sulfur content is 72 mg / l, 80 mg / l, 102 mg / l) each 9 milliliters , mix evenly, airtight, pass O 2 , O 2 Pressure is 0.08MPa, stirring, turn on xenon lamp (500W), carry out ultraviolet light irradiation, stop reaction after 10 hours, gasoline sulfur removal rate is 22%, 35% and 47% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com