Amoxicillin granule and production method thereof

A technology for amoxicillin and granules, which is applied in the field of preparing amoxicillin granules by micronization technology, can solve problems such as the application of micronization technology, and achieve the effects of reducing the amount of excipients, good dissolution rate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

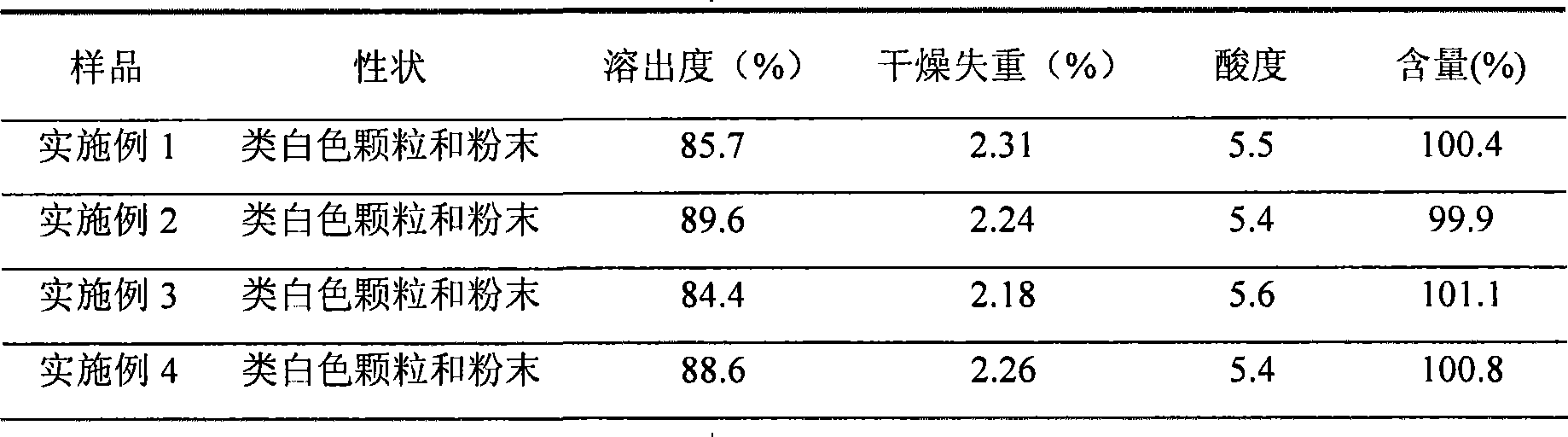

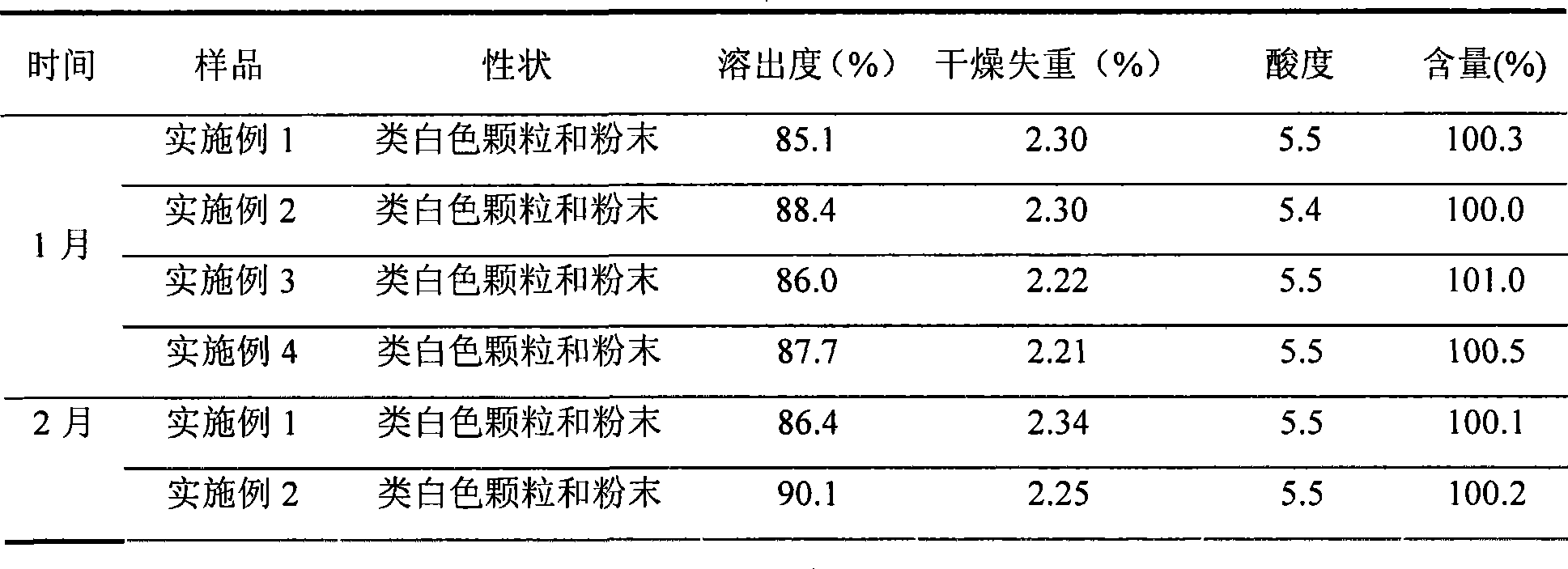

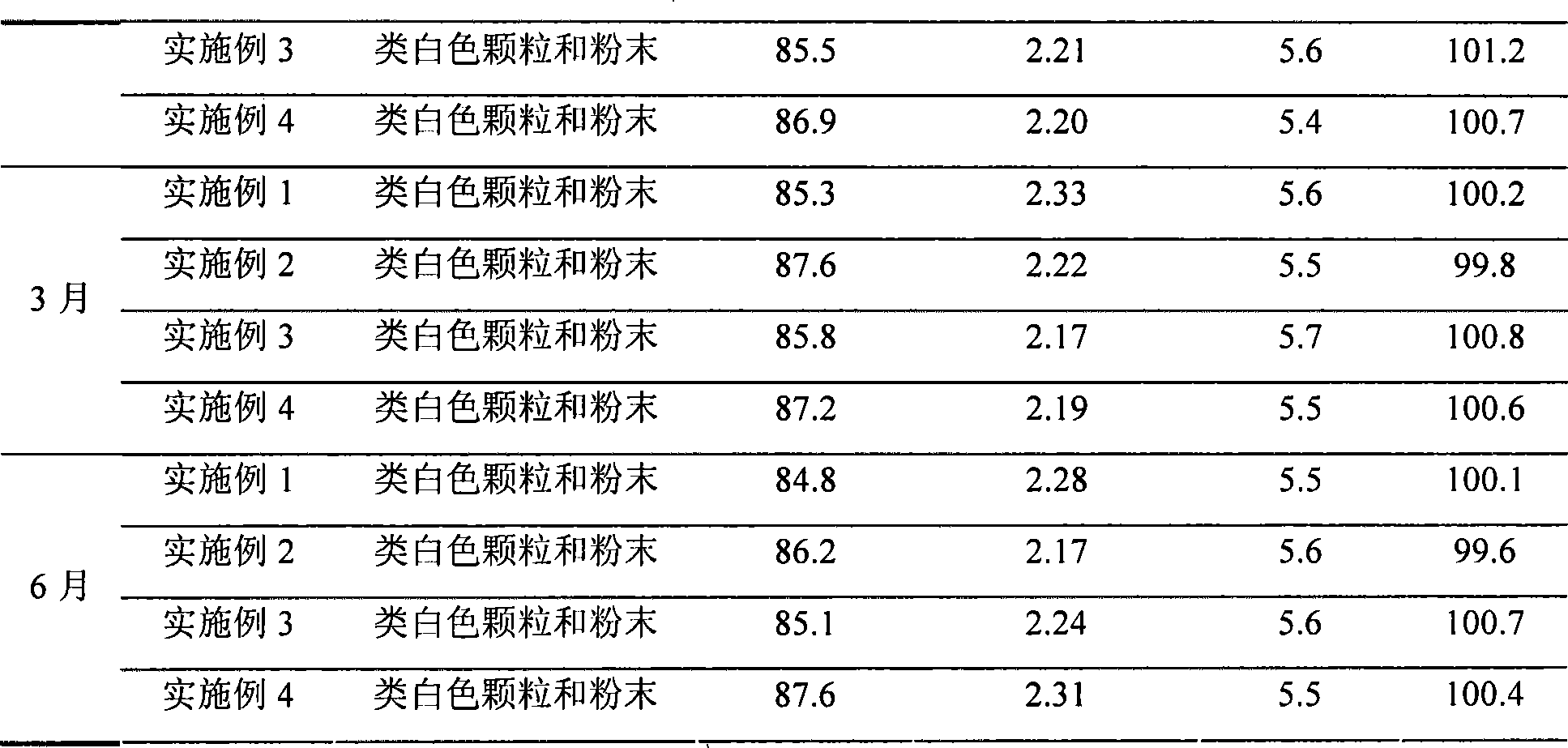

[0035] Example 1 Preparation of Amoxicillin Granules

[0036] Weigh 1250g of amoxicillin and 1000g of lactose and mix evenly, inject the mixture and dry nitrogen into the ultrafine pulverizer, use high-speed airflow to pulverize, the working pressure is 1.2MP, the internal working temperature is 50°C, the pulverization time is 40min, and then take out Fine powder, passed through a 500-mesh sieve, all passed, the fine powder and 100g sodium carboxymethyl cellulose, 2500g sucrose, 200g aspartame, 150g orange essence, 80g citric acid were mixed evenly, and the syrup solution was added to prepare the soft material , pass through a 20-mesh sieve to make wet granules, dry at 50°C, granulate through a 20-mesh sieve, and pack into bags.

Embodiment 2

[0037] Example 2 Preparation of Amoxicillin Granules

[0038] Weigh 1000g of amoxicillin and 800g of mannitol and mix evenly, inject the mixture and dry air into the ultrafine pulverizer, use high-speed airflow to pulverize, the working pressure is 1.0MP, the internal working temperature is 45°C, and the pulverization time is 30min, then Take out the fine powder, pass it through a 1000-mesh sieve, and pass it all, mix the fine powder with 150g hypromellose, 2300g sucrose, 500g sorbitol, 100g strawberry essence, 66g malic acid, add 5% povidone K30 ethanol solution and mix Prepare soft materials, pass through a 20-mesh sieve to make wet granules, dry at 50°C, granulate through a 20-mesh sieve, and pack into bags.

Embodiment 3

[0039] Example 3 Preparation of Amoxicillin Granules

[0040] Weigh 500g of amoxicillin and 800g of sucrose and mix evenly, inject the mixture and dry air into the ultrafine pulverizer, use high-speed airflow to pulverize, the working pressure is 1.1MP, the internal working temperature is 60°C, the pulverization time is 35min, and then take out Fine powder, passed through 800 mesh sieve, all passed, fine powder mixed with 200g mannitol, 35g sodium carboxymethyl cellulose, 18g orange essence, 46g tartaric acid, added 5% povidone K30 ethanol solution and mixed to prepare soft material, Pass through a 20-mesh sieve to make wet granules, dry at 50°C, sieve through a 20-mesh sieve, add 12.24 g of talcum powder, mix well, and pack into bags.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com