Method for preparing down-conversion fluorescent substrate material gadolinium sodium fluoride nanocrystalline

A technology of sodium gadolinium fluoride and matrix materials, which is applied in the field of preparation of down-conversion fluorescent matrix material sodium gadolinium fluoride nanocrystals, which can solve problems such as complex processes and achieve good repeatability, stable product quality, and simple processes and equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 0.01mol of gadolinium oxide, add a sufficient amount of perchloric acid with a concentration of 2mol / L, heat to dissolve, add deionized water to be constant to 100ml, obtain 0.2mol / L gadolinium perchlorate solution, and use high Chloric acid or sodium hydroxide solution to adjust its pH to 2;

[0023] (2) Weigh 7.4448g of disodium edetate and dissolve it in 80ml of deionized water, and after fully dissolving, set the volume to 100ml to obtain a 0.2mol / L disodium edetate solution;

[0024] (3) Weigh 2.0999g of sodium fluoride and dissolve it in 80ml of deionized water, and after fully dissolving, set the volume to 100ml to obtain a 0.5mol / L sodium fluoride solution;

[0025] (4) Take 5ml of the solution in step (1) and 5ml of the solution in step (2) and mix evenly. After fully stirring, add 15ml of the solution in step (3) to it, and centrifuge after aging for 1 hour. Wash 3 times and dry in a vacuum oven at 60°C.

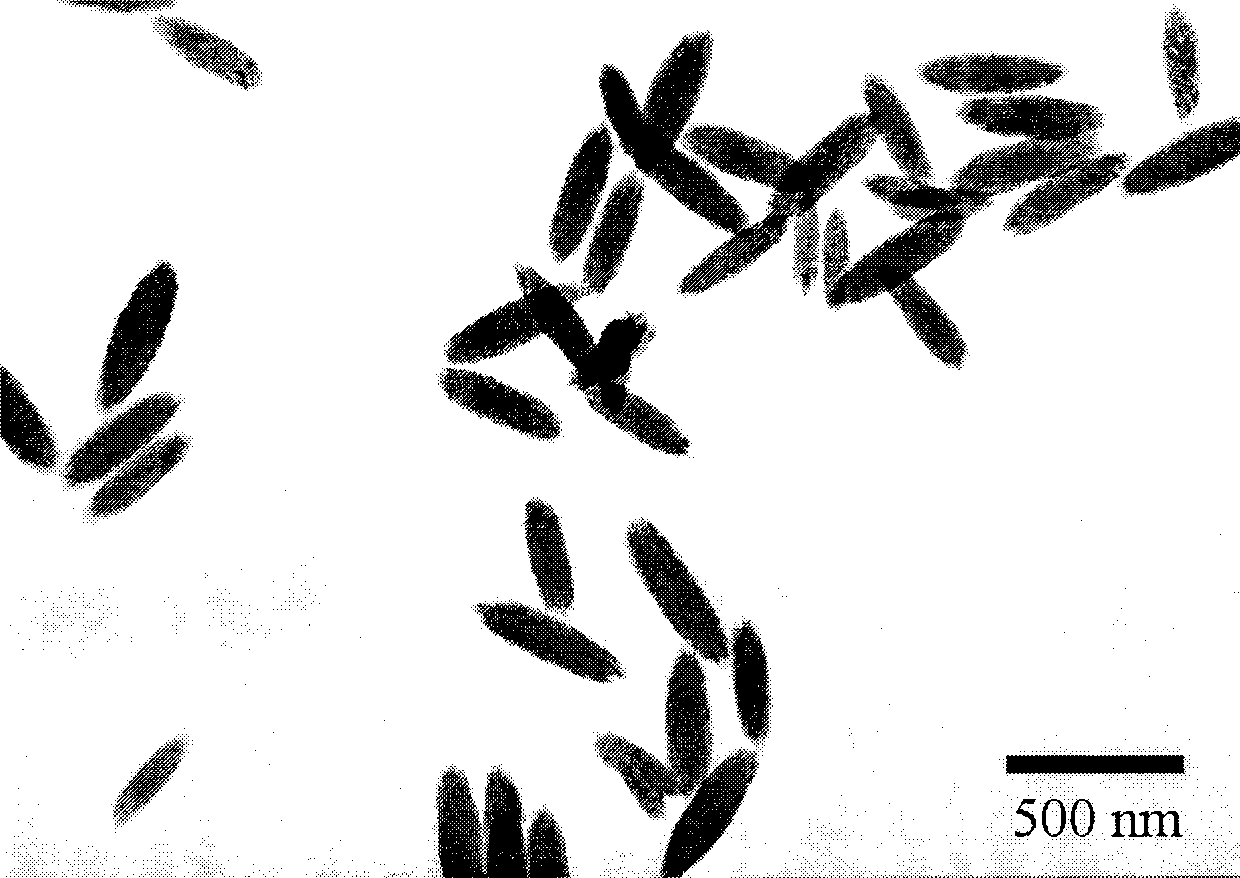

[0026] The X-ray diffraction pattern of th...

Embodiment 2

[0028] (1) Weigh 0.01mol of gadolinium oxide, add a sufficient amount of perchloric acid with a concentration of 2mol / L, heat to dissolve, add deionized water to be constant to 100ml, obtain 0.2mol / L gadolinium perchlorate solution, and use high Chloric acid or sodium hydroxide solution to adjust its pH to 2;

[0029] (2) Take 5.2938g of trisodium citrate and dissolve it in 80ml of deionized water, and after fully dissolving, set the volume to 100ml to obtain a 2mol / L trisodium citrate solution;

[0030] (3) Weigh 2.0999g of sodium fluoride and dissolve it in 80ml of deionized water, and after fully dissolving, set the volume to 100ml to obtain a 0.5mol / L sodium fluoride solution;

[0031] (4) Take 5ml of the solution in step (1) and 5ml of the solution in step (2) and mix evenly. After fully stirring, add 15ml of the solution in step (3) to it, and centrifuge after aging for 1 hour. Wash 3 times and dry in a vacuum oven at 60°C.

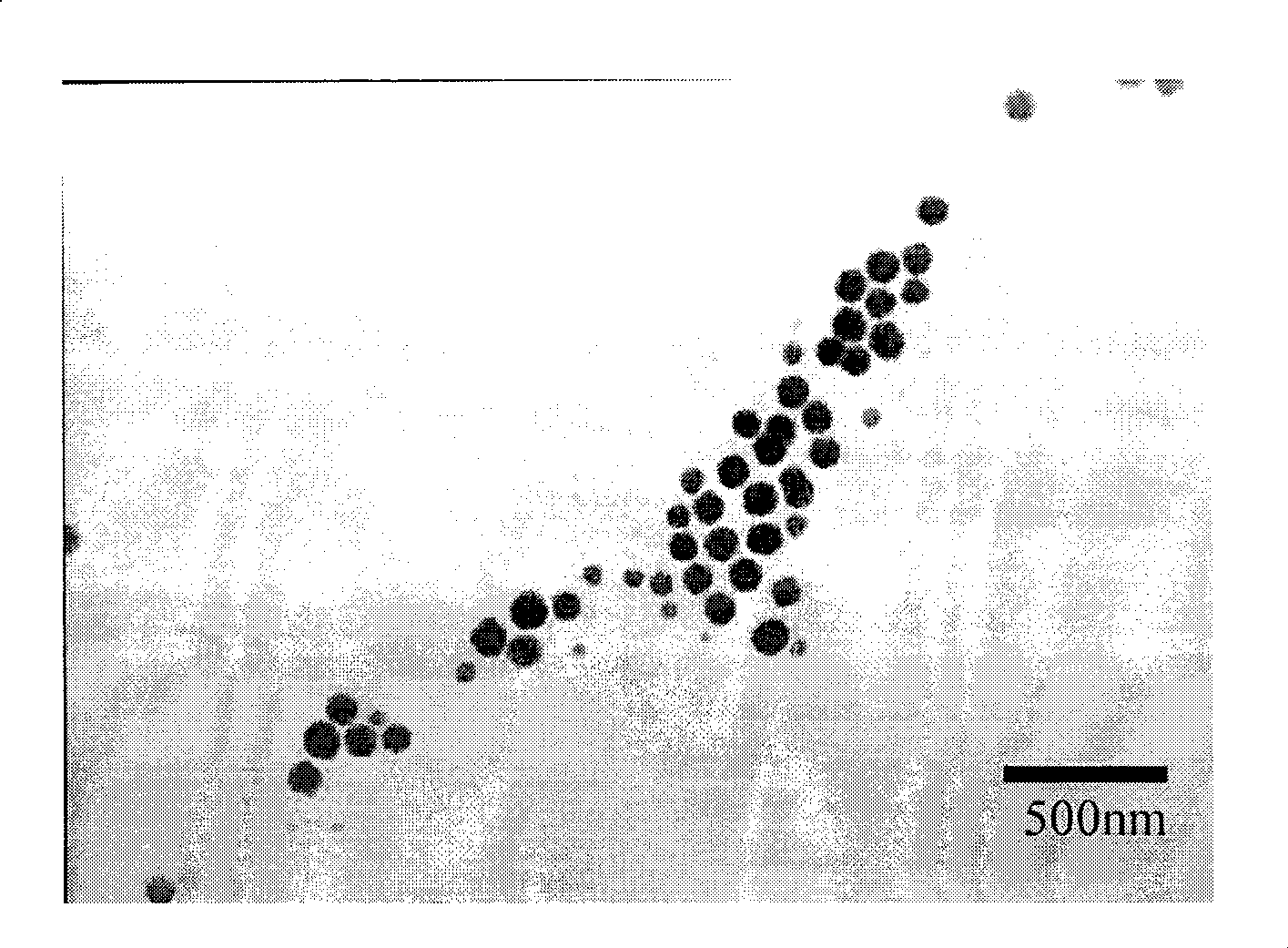

[0032] The X-ray diffraction pattern of the...

Embodiment 3

[0034] (1) Weigh 0.01mol of gadolinium oxide, add a sufficient amount of perchloric acid with a concentration of 2mol / L, heat to dissolve, add deionized water to be constant to 100ml, obtain 0.2mol / L gadolinium perchlorate solution, and use high Chloric acid or sodium hydroxide solution to adjust its pH to 2;

[0035] (2) Weigh 22.3344g of disodium edetate and dissolve it in 80ml of deionized water, and after fully dissolving, set the volume to 100ml to obtain a 0.6mol / L disodium edetate solution;

[0036] (3) Weigh 2.0999g of sodium fluoride and dissolve it in 80ml of deionized water, and after fully dissolving, set the volume to 100ml to obtain a 0.5mol / L sodium fluoride solution;

[0037] (4) Take 5ml of the solution in step (1) and 5ml of the solution in step (2) and mix evenly. After fully stirring, add 15ml of the solution in step (3) to it, and centrifuge after aging for 1 hour. Wash 3 times and dry in a vacuum oven at 60°C.

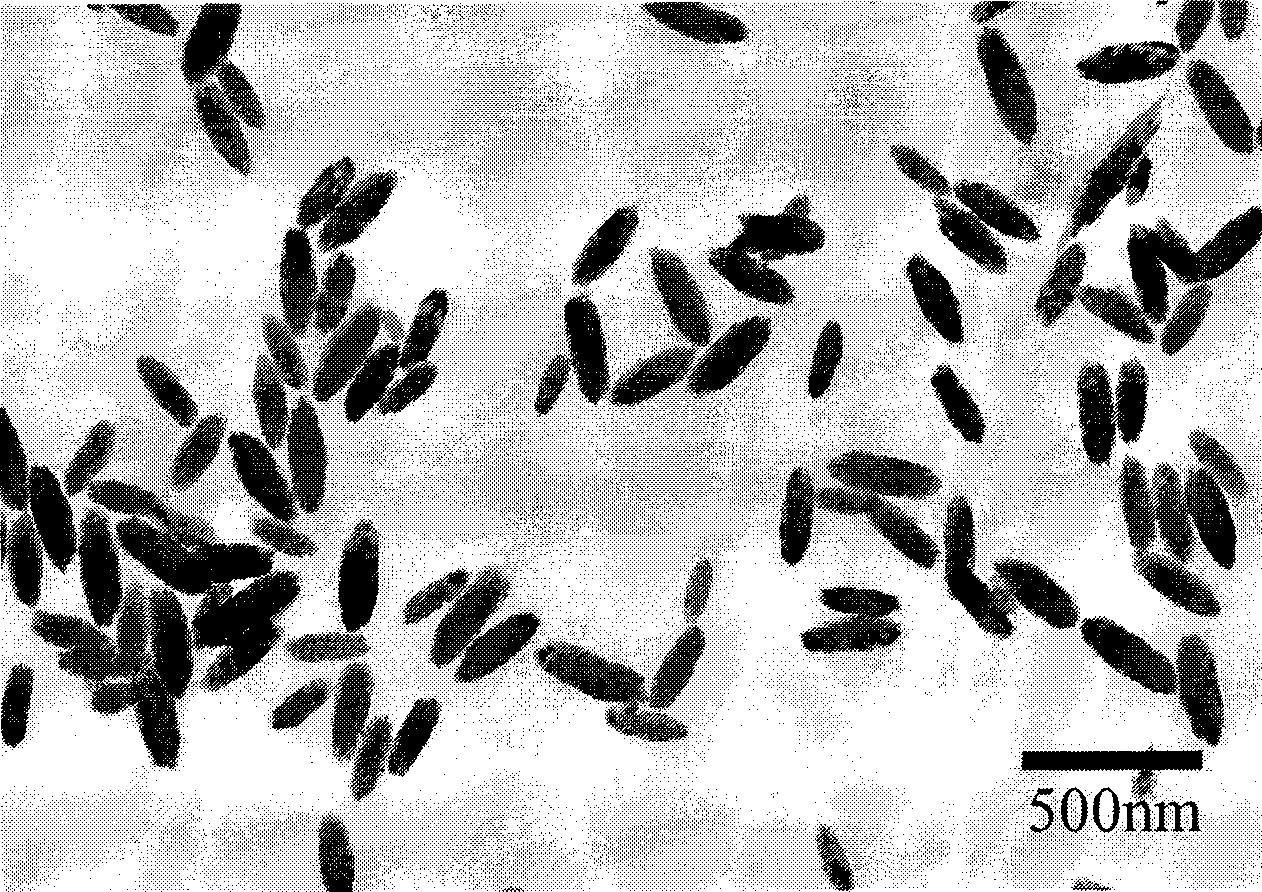

[0038] The transmission electron microsco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com