Process for producing sea urchin shaped polyaniline microsphere supported catalyst

A supported catalyst, polyaniline technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of reduced cleaning times, monomer diffusion, and poor control , increase processing steps and other issues, to achieve the effect of simple preparation method, easy separation and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Preparation of sea urchin-like polyaniline composite microspheres

[0021] 1) Monodisperse polystyrene microspheres are prepared by a soap-free emulsion polymerization method;

[0022] 2) Disperse the polystyrene microspheres synthesized in step 1) into deionized water to form 10gL -1 Emulsion, measure aniline monomer and add to the above emulsion, the concentration of aniline monomer is 15gL -1 , swell for 5 hours under magnetic stirring at 10°C;

[0023] 3) According to the molar ratio of the oxidizing agent to the monomer being 1:2, the oxidizing agent ferric nitrate was added to the mixed solution in step 2), reacted at 40°C for 12 hours, then centrifuged, washed with distilled water and absolute ethanol in turn, and dried The dark green sea urchin-like polyaniline composite microspheres were obtained.

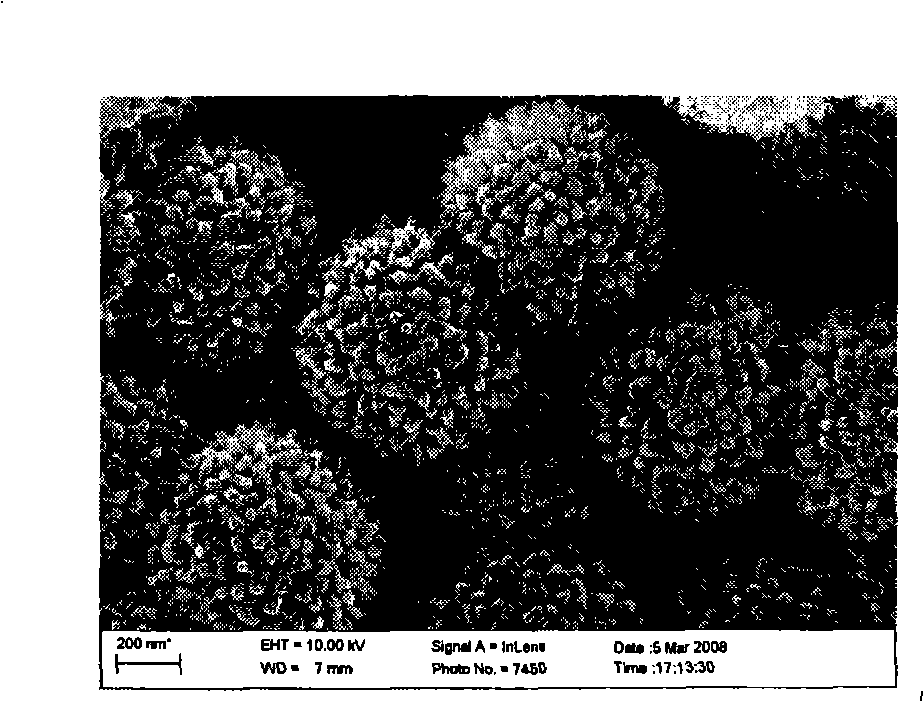

[0024] The prepared sea urchin-like polyaniline composite microspheres as figure 1 As shown, the diameter of the fiber is 15-30nm, the average length is 60-9...

Embodiment 2

[0029] 1. Preparation of sea urchin-like polyaniline composite microspheres

[0030] 1) Monodisperse polystyrene microspheres are prepared by a soap-free emulsion polymerization method;

[0031] 2) Disperse the polystyrene microspheres synthesized in step 1) into deionized water to form 15gL -1 Emulsion, measure aniline monomer and add to the above emulsion, the concentration of aniline monomer is 75gL -1 , swell for 5 hours under magnetic stirring at 20°C;

[0032] 3) According to the molar ratio of the oxidizing agent to the monomer being 1:4, add the oxidizing agent ferric chloride to the mixed solution in step 2), react at 20°C for 20 hours, then centrifuge, wash with distilled water and absolute ethanol in turn, and dry Finally, dark green sea urchin-like polyaniline composite microspheres were obtained.

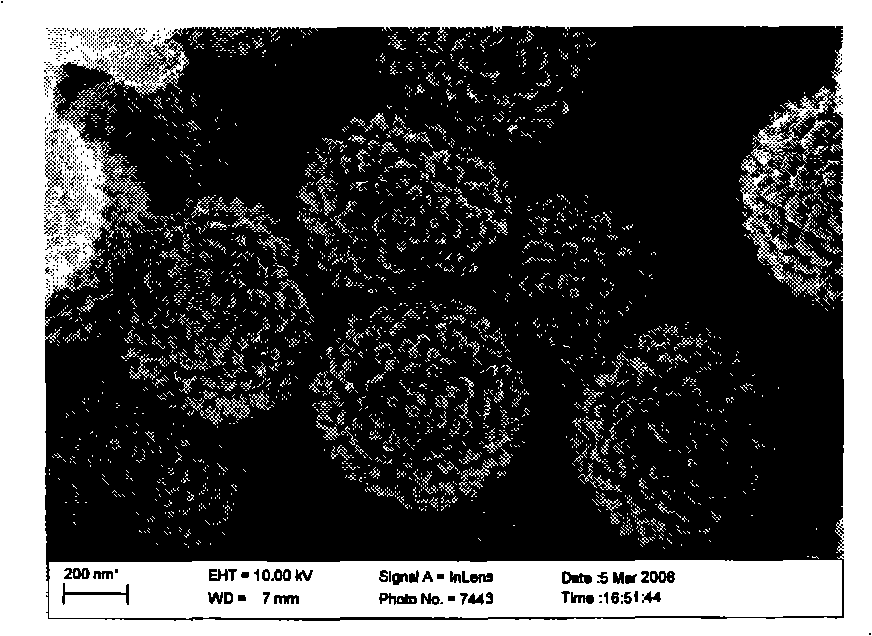

[0033] The prepared sea urchin-like polyaniline composite microspheres as figure 2 As shown, the diameter of the fiber is 20-50nm, the average length is 40-80nm, a...

Embodiment 3

[0038] 1. Preparation of sea urchin-like polyaniline composite microspheres

[0039] 1) Monodisperse polystyrene microspheres are prepared by a soap-free emulsion polymerization method;

[0040] 2) Disperse the polystyrene microspheres synthesized in step 1) into deionized water to form 20gL -1 Emulsion, measure aniline monomer and add to the above emulsion, the concentration of aniline monomer is 100gL -1 , swell for 6 hours under magnetic stirring at 30°C;

[0041] 3) According to the molar ratio of the oxidizing agent to the monomer being 1:4, the oxidizing agent ferric sulfate was added to the mixed solution in step 2), reacted at 30°C for 30 hours, then centrifuged, washed with distilled water and absolute ethanol in turn, and dried The dark green sea urchin-like polyaniline composite microspheres were obtained.

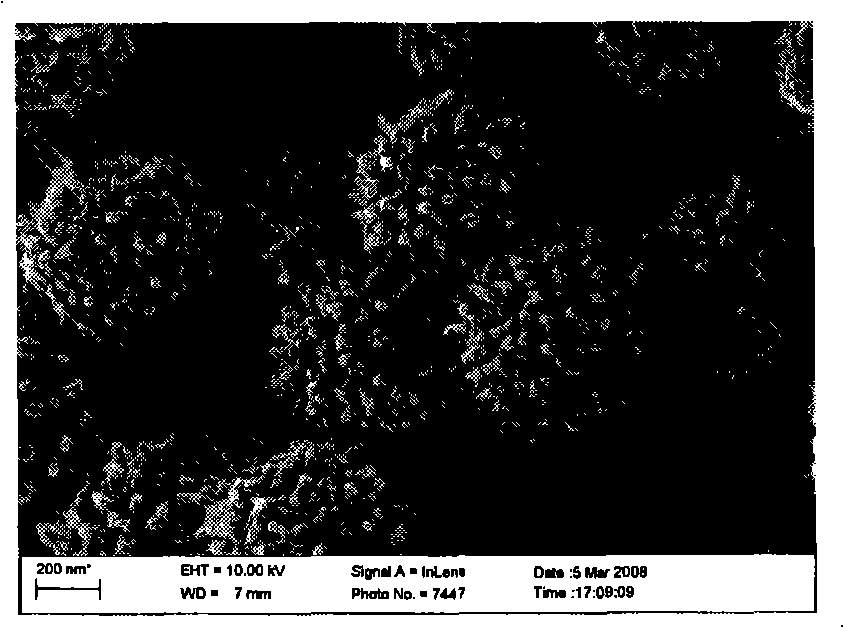

[0042] The prepared sea urchin-like polyaniline composite microspheres as image 3 As shown, the diameter of the fiber is 5-40nm, the average length is 70-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com