Watersoluble fluorine-carbon modified elastic paint for exterior wall of construction

A water-based fluorocarbon, building exterior wall technology, applied in coatings, latex paints, etc., can solve the problems of surface contamination of elastic coatings, high sulfur dioxide content, and little resistance to acid rain and aging of elastic coatings. Effects of VOC Emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The coating formulation of the present invention is: 200.0g deionized water, 30.0g propylene glycol, 7.0g dispersant SN5027, 2.0g multifunctional additive AMP-95, 3.0g defoamer NXZ, 1.0g Casson preservative LXE, 2.0g Anti-mildew and anti-algae agent R-2000, 150.0g rutile titanium dioxide, 180.0g precipitated barium sulfate, 100.0g fluorocarbon emulsion, 300.0g acrylic elastic emulsion, 10.0g film-forming agent alcohol ester-12, 4.0g rheological aid Agent R-2020, 8.0g thickener TT-935. Add co-solvent, dispersant, multi-functional additive, 1 / 2 defoamer, preservative, anti-mold and anti-algae agent, rutile titanium dioxide and precipitated barium sulfate in water, disperse at high speed until the fineness is acceptable, and then add fluorine Carbon emulsion and acrylic elastic emulsion, 1 / 2 defoamer, film-forming aid, rheological aid and thickener, adjusted to a suitable viscosity, and finally the finished elastic coating is obtained.

Embodiment 2

[0026] The coating formulation of the present invention is: 150.0g deionized water, 25.0g ethylene glycol, 8.0g dispersant SN5027, 2.5g multifunctional additive AMP-95, 3.5g defoamer DFC165, 1.5g BIT preservative PROXELAQ, 4.0 g anti-mildew and anti-algae agent R-2000, 190.0g rutile titanium dioxide, 110.0g ultra-fine quartz powder, 125.0g fluorocarbon emulsion, 350.0g acrylic elastic emulsion, 12.0g film-forming aid benzyl alcohol, 5.0g rheological aid Agent R-2020, 7.0g thickener TT-935. The preparation process is the same as in Example 1.

Embodiment 3

[0028] The coating formula of the present invention is: 100.0g deionized water, 20.0g propylene glycol, 9.0g dispersant SN5027, 3.0g multifunctional additive AMP-95, 4.0g defoamer NXZ, 2.0g BIT preservative PROXELAQ, 6.0g anti-corrosion agent Mildew and algae inhibitor R-2000, 230.0g rutile titanium dioxide, 50.0g feldspar powder, 150.0g fluorocarbon emulsion, 400.0g acrylic elastic emulsion, 15.0g film-forming aid ethylene glycol butyl ether, 6.0g rheology additive R-2020, 6.0g thickener TT-935. The preparation process is the same as in Example 1.

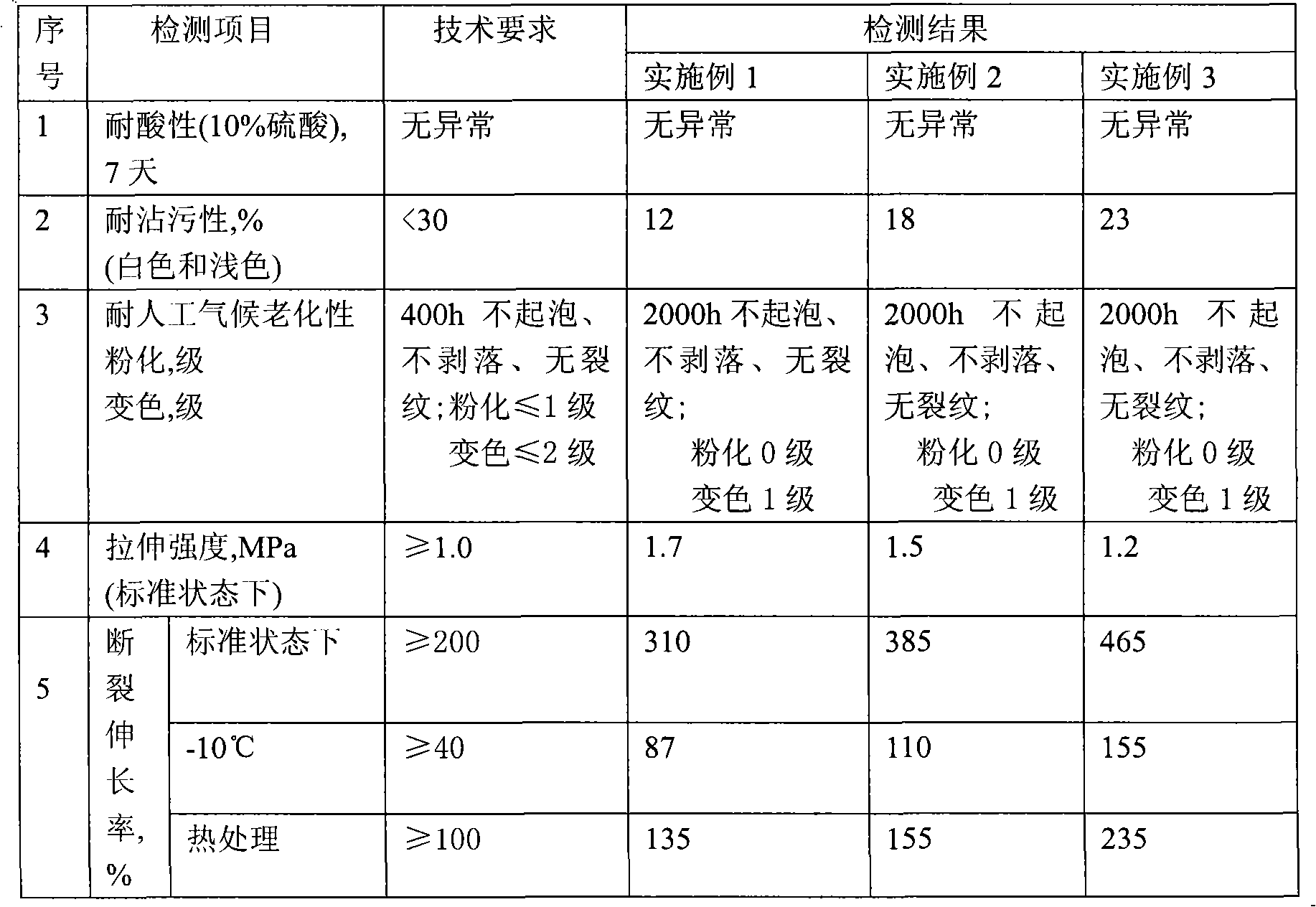

[0029] The performance of embodiment gained elastic paint is as follows:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com