Aqueous emulsion containing chlorfenapyr and preparation method thereof

A technology of chlorfenapyr and water-emulsion, which is applied in the field of water-emulsion containing chlorfenapyr and its preparation, can solve the problems of compound water-emulsion with no chlorfenapyr component, no registration of water-emulsion, etc., and achieve the purpose of delaying pests The development of drug resistance, the avoidance of flammable and explosive phenomena, and the effect of expanding the insecticidal spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

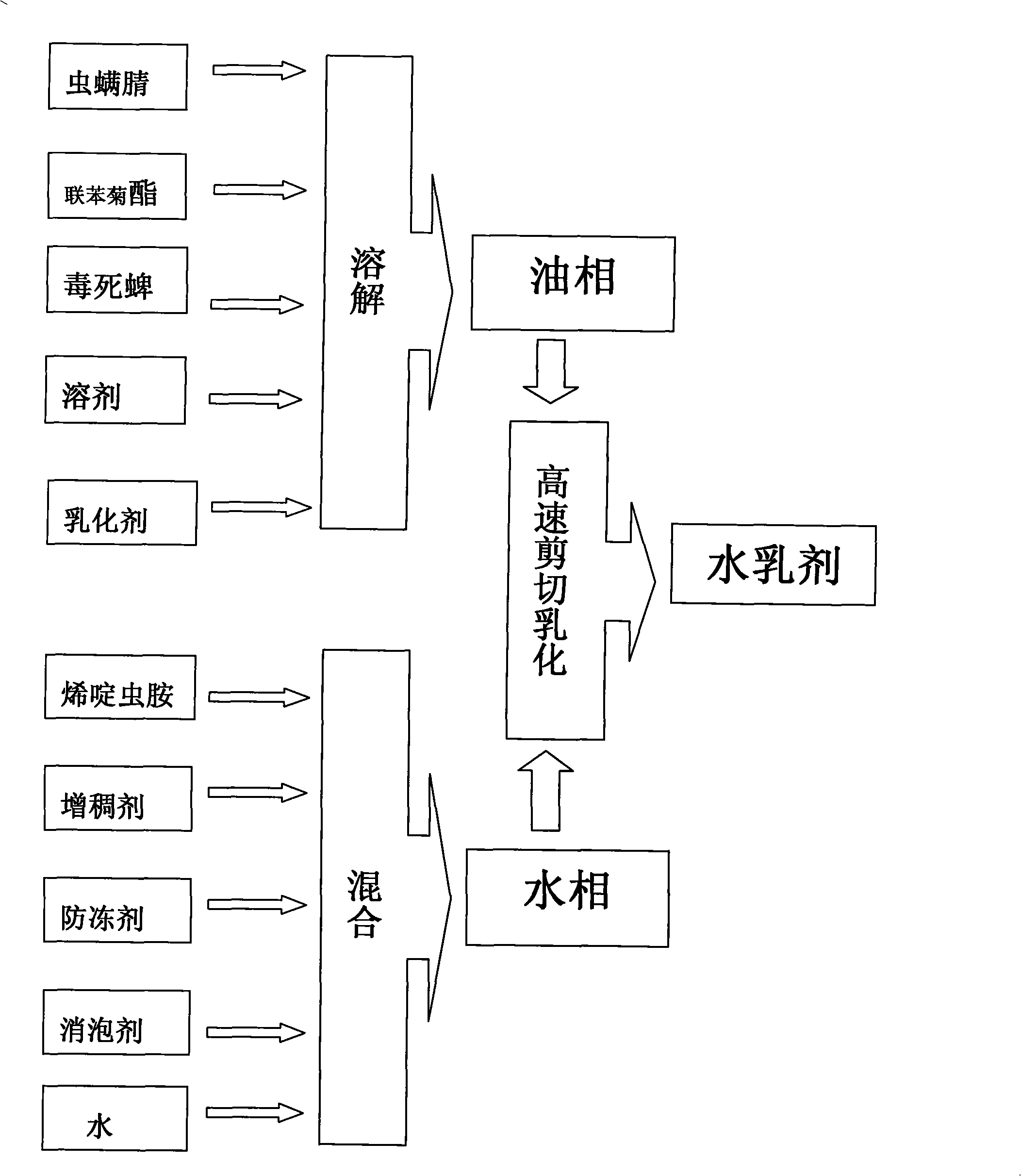

Method used

Image

Examples

Embodiment 1

[0025] Calculated by taking the finished water emulsion as the weight of 100kg. Dissolve 10kg of chlorfenapyr (Zibai) with 10kg of cyclohexanone solvent and stir for 10 minutes at room temperature, then add emulsifier 5kg of alkylphenol polyoxyethylene ether phosphate, 1kg of calcium dodecylbenzenesulfonate, 3kg of Ethylene glycol antifreeze agent, 0.05kg defoamer, make up to 100kg with water, stir and mix evenly, then shear with a high-shear emulsifier for 0.5 hour to form a milky white opaque liquid, and obtain 10% chlorfenapyr water emulsion.

[0026] Preparation:

[0027] a. In a container with electric stirring, add chlorfenapyr and organic solvent cyclohexanone, start stirring until chlorfenapyr dissolves, then add emulsifier according to the above formula, and stir to form a uniform oil phase. Reserve as an oil phase.

[0028] b. In a mixing kettle with high-speed shear, add the antifreeze and defoamer into the water sequentially under stirring until they are complete...

Embodiment 2

[0031] Calculated by taking the finished water emulsion as the weight of 100kg. Dissolve 5kg of chlorfenapyr (difenapyr) and 10kg of bifenthrin (difenthrin) in 15kg of xylene solvent at room temperature for 0.5 hours, then add emulsifier 4kg of alkylphenol polyoxyethylene ether phosphate, 2kg of fat Alcohol polyoxyethylene ether phosphate, 3kg ethylene glycol antifreeze, 0.1kg defoamer and water are added to 100kg, after stirring for 0.5 hours, after 0.5 hours of shearing by a high-shear emulsifier, it becomes a milky white opaque liquid, to obtain 15 % chlorfenapyr · bifenthrin aqueous emulsion.

[0032] Preparation:

[0033] a. Add the original drug of chlorfenapyr and bifenthrin into the organic solvent xylene, stir continuously until it is completely dissolved, then add the emulsifier alkylphenol polyoxyethylene ether phosphate, fatty alcohol polyoxyethylene Ether phosphate, stir until well mixed, and set aside as the oil phase.

[0034] b. In a mixing kettle with high-...

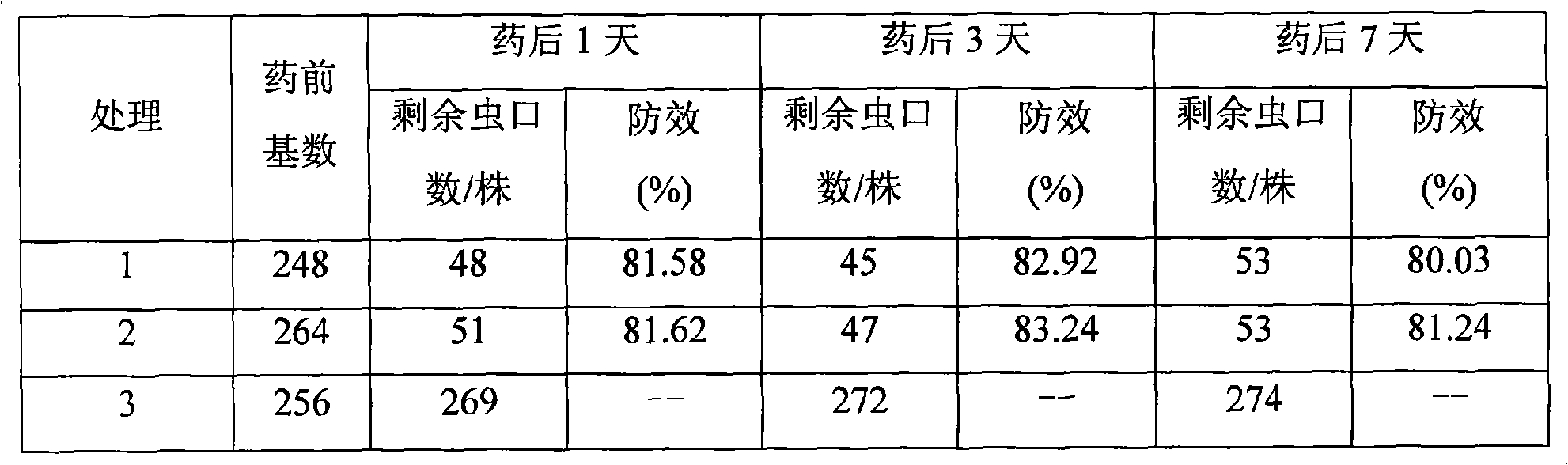

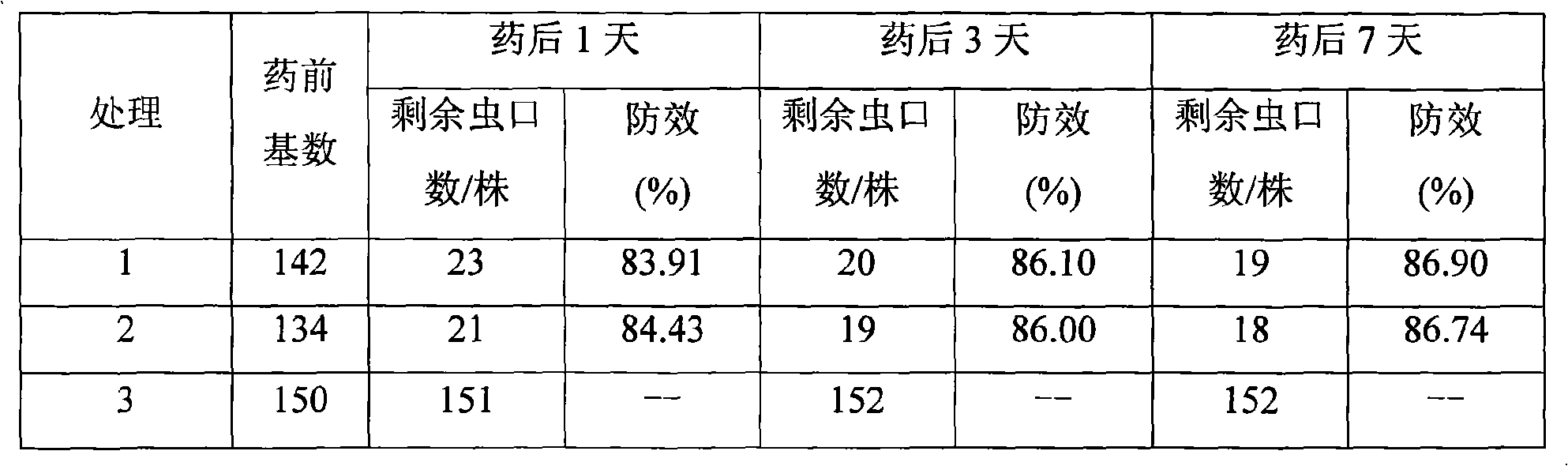

Embodiment 3

[0037] Calculated by taking the finished water emulsion as the weight of 100kg. Use 10kg xylene and 6kg cyclohexanone as a solvent to dissolve 5kg of chlorpyrifos and 20kg of chlorpyrifos at room temperature for 0.5 hours, then add emulsifier 4kg of alkylphenol polyoxyethylene ether phosphate , 3kg alkyl aryl polyoxypropylene polyoxyethylene ether, 1kg calcium dodecylbenzene sulfonate, 3kg ethylene glycol antifreeze, 0.05kg defoamer, water to make up to 100kg, after mixing evenly, after high shear Cutting and emulsifying machine shears for 1 hour to become a milky white opaque liquid, that is, a 25% insecticidal aqueous emulsion of chlorpyrifos and chlorpyrifos.

[0038] Preparation:

[0039] a. Add the chlorpyrifos and chlorpyrifos into the organic solvent xylene, stir continuously until the chlorpyrifos and chlorpyrifos are dissolved, then add the emulsifiers alkylphenol polyoxyethylene ether phosphate, alkyl aryl Polyoxypropylene polyoxyethylene ether, calcium dodecylbenz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com