Flame-retardant decorative veneer

A decorative paste and panel technology, which is applied in the jointing of wooden veneers, manufacturing tools, wood treatment, etc., can solve the problems of life safety threats, economic losses, casualties, etc., and achieve simple production process and low cost of flame retardant treatment , the effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Put the 1.7mm poplar veneer into the flame retardant aqueous solution (the flame retardant is composed of the following mass ratio components: 50 parts of ammonium oligophosphate, 15 parts of ammonium phosphate, 5 parts of ammonium pyrophosphate, 5 parts of urea phosphate , boric acid 10 parts, pentaerythritol 15 parts), flame retardant temperature 50 ℃, concentration 50%, take out after soaking for 30 minutes, balance the moisture content to 20% under natural conditions, and dry it with a mesh belt dryer to a moisture content of 8 %.

[0029] Mixed adhesive: take 100 parts of melamine resin glue, add 60 parts of talcum powder to the melamine resin glue, add 0.5 part of curing agent ammonium chloride, and mix well to obtain a mixed adhesive.

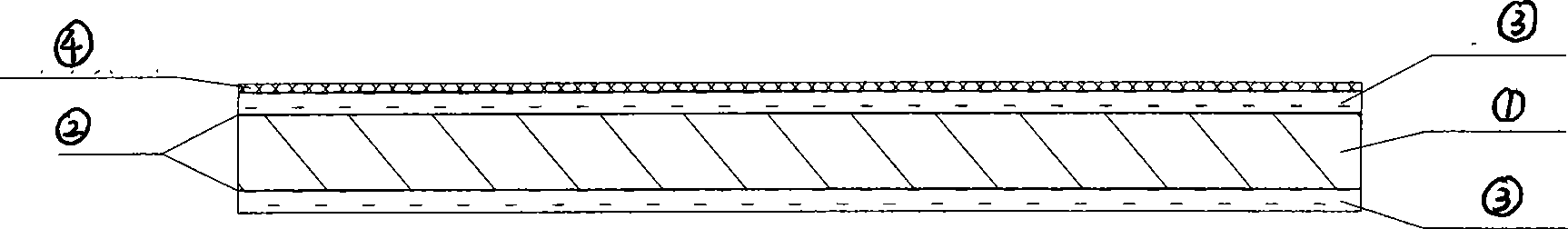

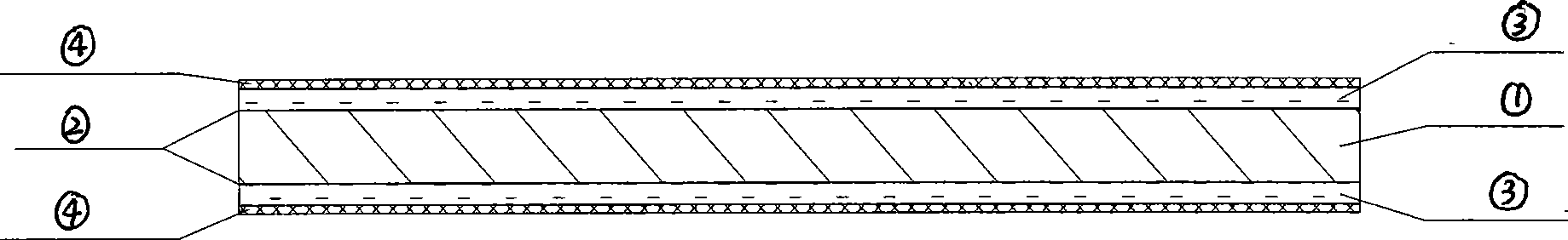

[0030] Use the above mixed adhesive to glue the veneer, the amount of glue is 400g / m 2 . The 0.65mm Okoume veneer is placed on the top and bottom of the poplar veneer to form a slab. The slab is put into a cold press for 30 minu...

Embodiment 2

[0035] Put the 2.6mm miscellaneous wood veneer into the flame retardant aqueous solution (the flame retardant is composed of the following mass ratio components: 62 parts of ammonium oligophosphate, 8 parts of ammonium phosphate, 5 parts of ammonium pyrophosphate, 5 parts of urea phosphate , 5 parts of boric acid, 15 parts of pentaerythritol), flame retardant temperature 50 ℃, concentration 35%, take out after soaking for 50 minutes, balance the moisture content to 20% under natural conditions, and dry it with a mesh belt dryer to a moisture content of 8 %.

[0036] Mixed adhesive: take 100 parts of melamine resin glue, add 60 parts of talcum powder to the melamine resin glue, add 0.5 part of curing agent ammonium chloride, and mix well to obtain a mixed adhesive.

[0037] Use the above mixed adhesive to glue the veneer, the amount of glue is 400g / m 2 . The 0.65mm Okoume veneer is placed on the top and bottom of the miscellaneous wood veneer to form a slab. The slab is put i...

Embodiment 3

[0042] Put the 1.7mm eucalyptus veneer into the flame retardant aqueous solution (the flame retardant is composed of the following mass ratio components: 60 parts of ammonium oligophosphate, 10 parts of ammonium phosphate, 8 parts of ammonium pyrophosphate, 7 parts of urea phosphate , 5 parts of boric acid, 10 parts of pentaerythritol), flame retardant temperature 60 ℃, concentration 25%, take out after soaking for 30 minutes, balance the moisture content to 20% under natural conditions, and dry it with a mesh belt dryer to a moisture content of 12 %.

[0043] Mixed adhesive: Take 70 parts of urea-formaldehyde resin glue and 30 parts of melamine resin glue, add 50 parts of talc powder, add 50 parts of high clay, add 0.2 parts of curing agent phosphoric acid, and 0.5 parts of curing agent ammonium chloride, and mix well to obtain a mixed adhesive.

[0044] Use the above mixed adhesive to glue the veneer, the amount of glue is 650g / m 2 . The 9-layer 1.7mm eucalyptus veneer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com