Method for preparing air self-purifying function fabric of photochemical catalyst coating

A functional fabric and self-purification technology, applied in textile and papermaking, fiber treatment, irradiation and other directions, can solve problems such as influence effect and catalyst falling off, and achieve the effect of low cost, simple preparation method, high efficiency and rapid air purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

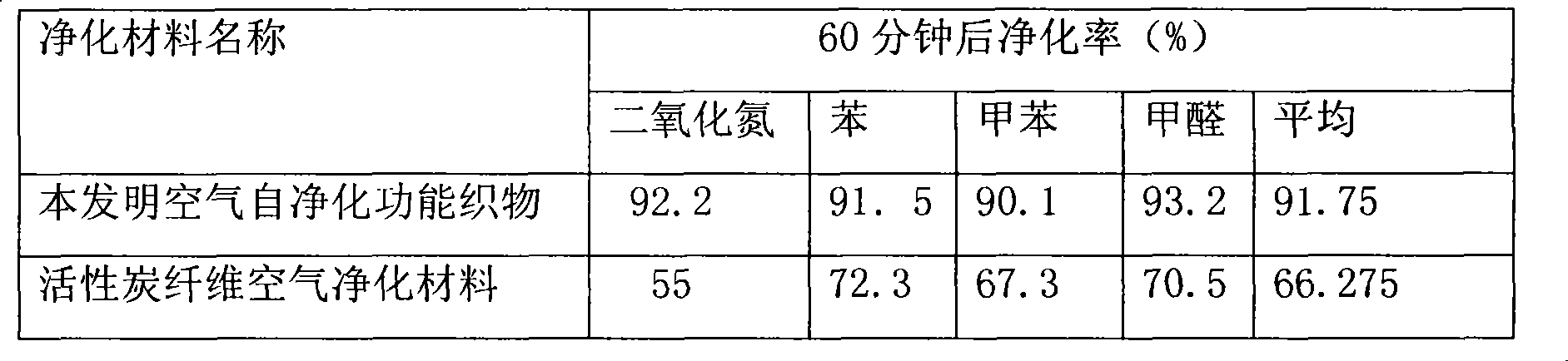

Embodiment 1

[0027] (1) Pretreatment of the base cloth surface:

[0028] Use a solution containing 0.3g / l ethanol or 0.05g / l acetone or 0.2g / l oxalic acid or 0.3g / l chloroform to ultrasonically clean the surface of cotton fabrics at 60°C for 20 minutes, wash twice with boiling water, and wash once with household detergent time, drying;

[0029] Use a volume ratio of 7:16:10 deionized water, methanol and ether as the dispersing agent of the fiber protection agent, adjust the pH value of the dispersion protection system to about 9.5 with ammonia water, and shake it in an ultrasonic cleaner at 20°C for 15 minutes to make it Disperse evenly, and then soak the fabric in the dispersion protection system at about 30°C for more than 6 hours to make the two fully adsorb, wash off the mechanically deposited fiber protection agent on the fabric with distilled water, and then bake the fiber protection agent and fabric Fibers bond to each other;

[0030] Treat the base fabric with an aqueous solution...

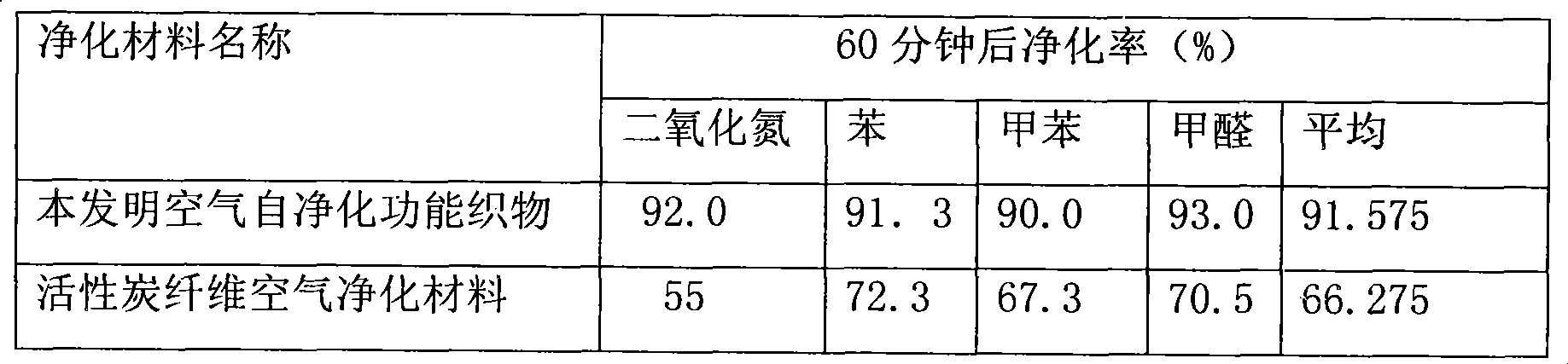

Embodiment 2

[0037] A preparation method of a photocatalytic coated air self-purifying functional fabric, the specific steps are:

[0038] (1) Pretreatment of the base cloth surface:

[0039] Use a solution containing 0.4g / l ethanol or 0.1g / l acetone or 0.3g / l oxalic acid or 0.4g / l chloroform to clean the surface of the base cloth with ultrasonic waves at 65°C for 30 minutes, wash with boiling water for 3 times, and wash with household detergent for 2 time, drying;

[0040] Use a volume ratio of 8.5:18:11 deionized water, methanol and ether as the dispersing agent of the fiber protection agent, adjust the pH value of the dispersion protection system to about 10.5 with ammonia water, and shake it in an ultrasonic cleaner at 25°C for 20 minutes to make it Disperse evenly, then soak the base cloth in the dispersion protection system at about 35°C for more than 7 hours to make the two fully adsorb, wash off the mechanically deposited fiber protection agent on the fabric with distilled water, ...

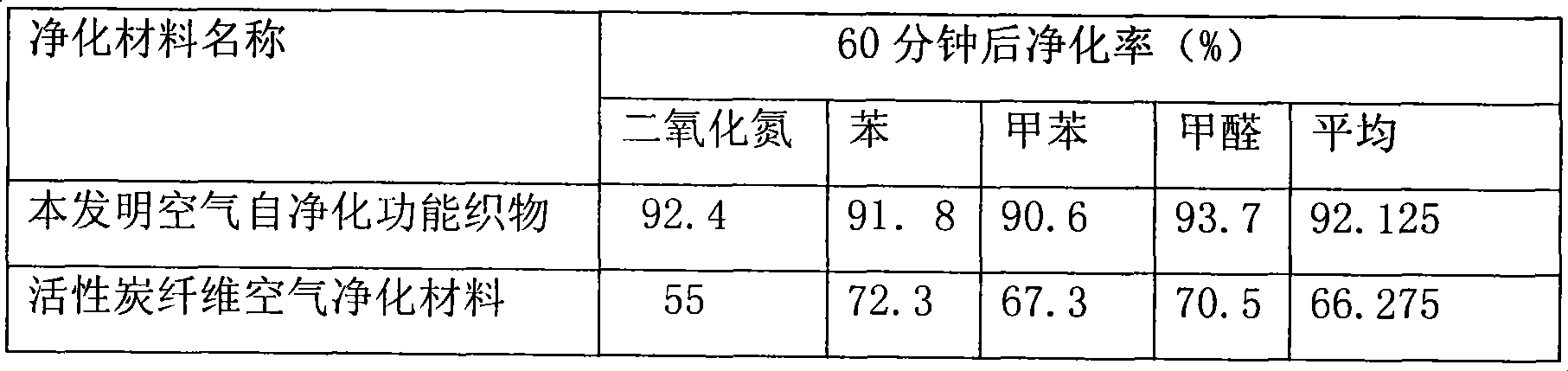

Embodiment 3

[0048] (1) Pretreatment of the base cloth surface:

[0049] Use a solution containing 0.5g / l ethanol or 0.15g / l acetone or 0.4g / l oxalic acid or 0.5g / l chloroform to clean the surface of the cotton fabric with ultrasonic waves at 70°C for 40 minutes, wash it with boiling water 4 times, and wash it with household detergent for 3 times time, drying;

[0050] Use a volume ratio of 10:20:12 deionized water, methanol and ether as the dispersing agent of the fiber protection agent, adjust the pH value of the dispersion protection system to about 11.5 with ammonia water, and shake it in an ultrasonic cleaner at 30°C for 25 minutes to make it Disperse evenly, then soak the fabric in the dispersion protection system at about 40°C for more than 8 hours to make the two fully adsorb, wash off the mechanically deposited fiber protective agent on the fabric with distilled water, and then bake the fiber protective agent and fabric Fibers bond to each other;

[0051] Treat the base fabric w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com