Leadless welding alloy for welding electronic elements

A technology of lead-free solder alloys and electronic components, applied in welding/cutting media/materials, welding media, welding equipment, etc., can solve problems such as electric corrosion, excessive welding slag, poor corrosion resistance, etc., and achieve a dense alloy structure , Improve the mechanical properties and refine the alloy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

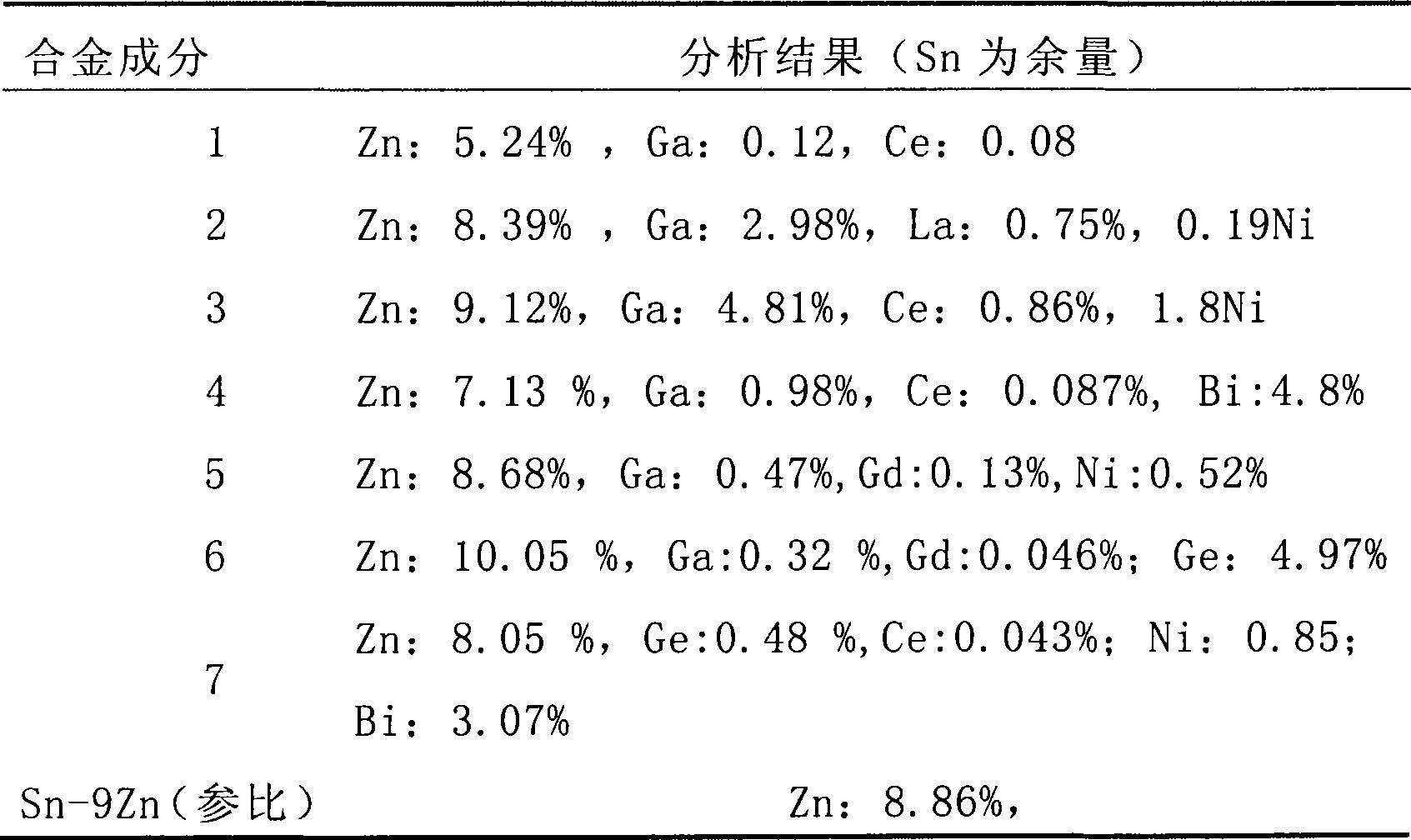

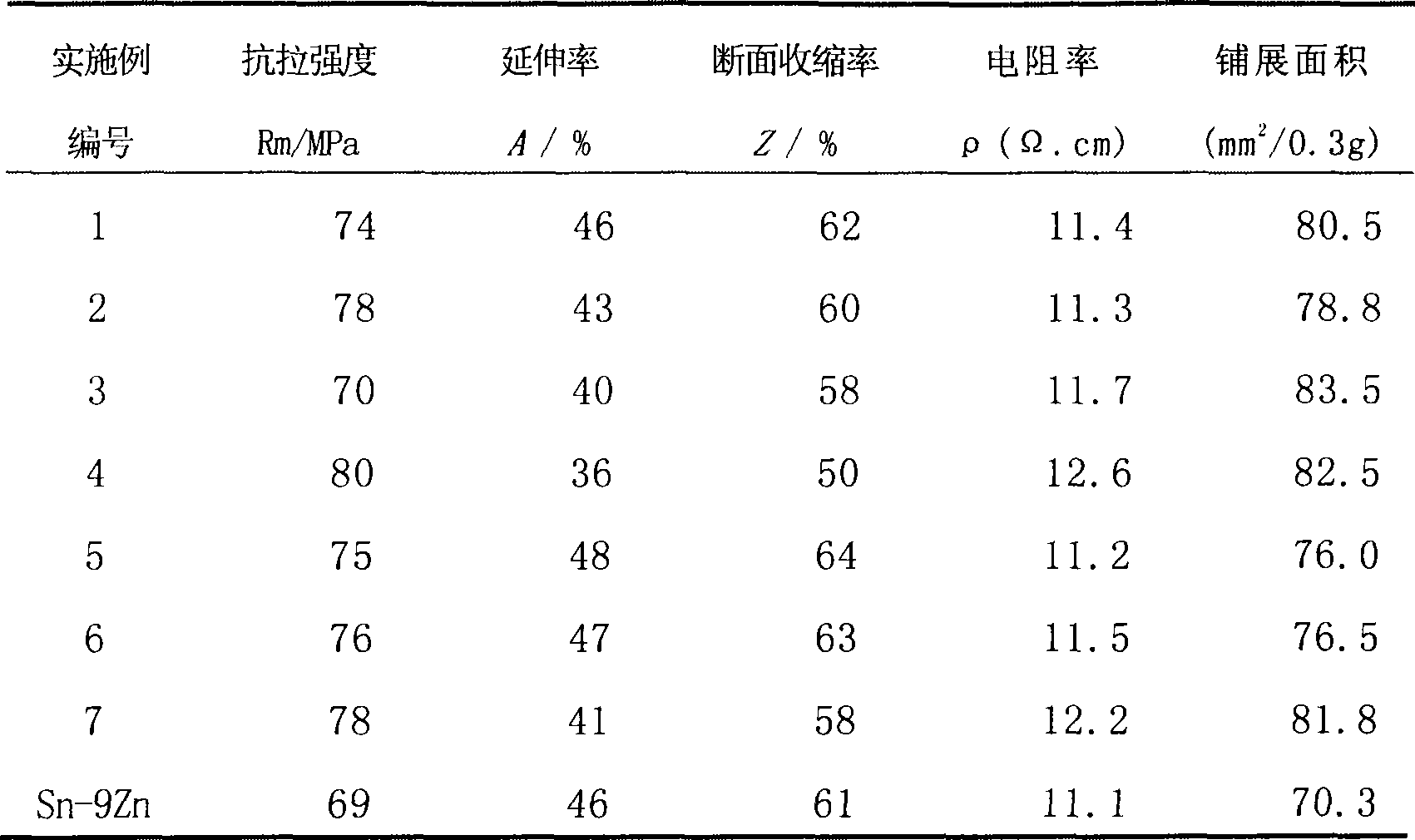

Embodiment 1

[0023] Example 1: 100g of rare earth-containing tin-zinc-gallium lead-free solder, its composition and weight percentage are: 5% Zn, 0.1% Ga, 0.1% Ce, and the balance is Sn. Weigh 230g of LiCl and KCl with a mass percentage of 1.3:1, mix them evenly, put them in an alumina crucible, heat to 500°C, put Sn into the crucible after melting, put it back into the furnace to melt Sn completely, and then add Ga. Zn, and Ce, keep stirring, heat preservation for 2h, and pre-cool it out of the furnace. After the covering agent starts to crystallize and salt grains appear, the slag is quickly removed, and then cast.

Embodiment 2

[0024] Example 2: 100g of rare earth-containing tin-zinc-gallium lead-free solder, its composition and weight percentage are: 8% Zn, 3% Ga, 0.8% La, 0.2 Ni, and the balance is Sn. Weigh 230g of LiCl and KCl with a mass percentage of 1.3:1, mix them evenly, put them in an alumina crucible, heat to 500°C, put Sn into the crucible after melting, put it back into the furnace to melt Sn completely, and then add Ga. Zn, and La, keep stirring, heat preservation for 2h, pre-cooling out of the furnace, after the covering agent begins to crystallize and salt grains appear, quickly slag off, and then cast.

Embodiment 3

[0025] Embodiment 3: 100g of rare earth-containing tin-zinc-gallium lead-free solder, its composition and weight percentage are: 10% Zn, 5% Ga, 1% Ce, 2% Ni, and the balance is Sn. Weigh 230g of LiCl and KCl with a mass percentage of 1.3:1, mix them evenly, put them in an alumina crucible, heat to 500°C, put Sn into the crucible after melting, put it back into the furnace to melt Sn completely, and then add Ga. Zn, and Ce, keep stirring, heat preservation for 2h, and pre-cool it out of the furnace. After the covering agent starts to crystallize and salt grains appear, the slag is quickly removed, and then cast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com