Method for preparing asiatic acid by asiaticoside basic hydrolysis

A technology of asiatic acid and asiaticoside, which is applied in the field of asiatic acid prepared by hydrolysis of asiaticoside base, can solve the problems of large solvent consumption, time-consuming and labor-intensive, etc., and achieve high yield and purity, simple process and low investment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

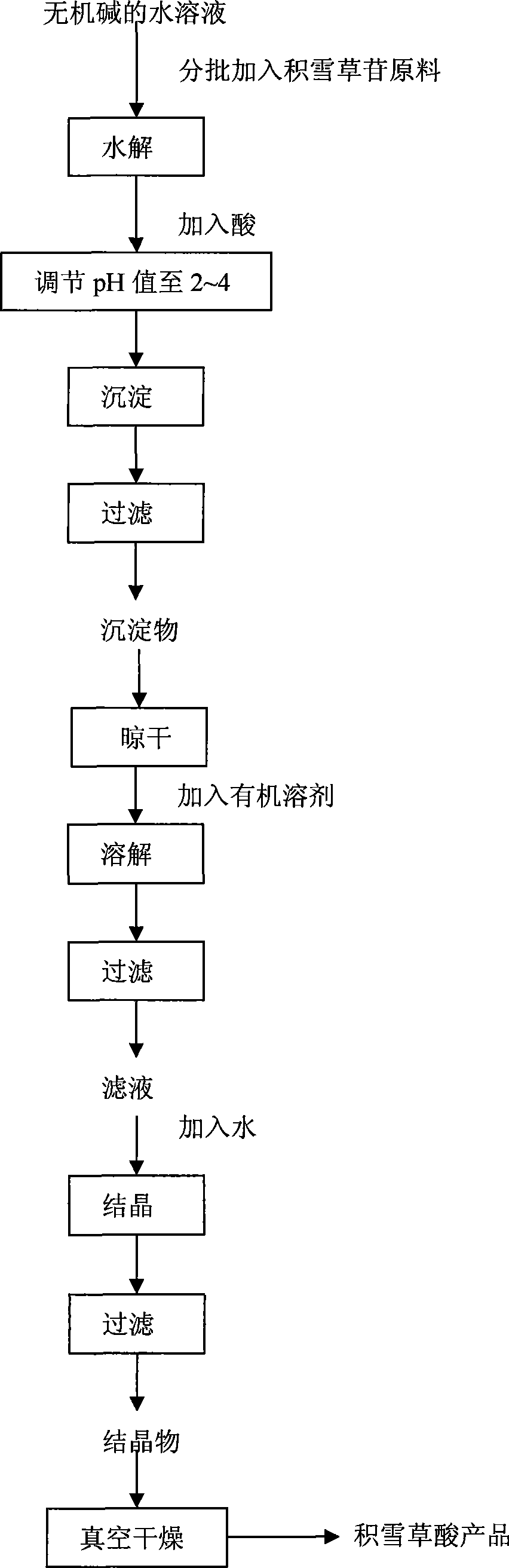

Method used

Image

Examples

Embodiment 1

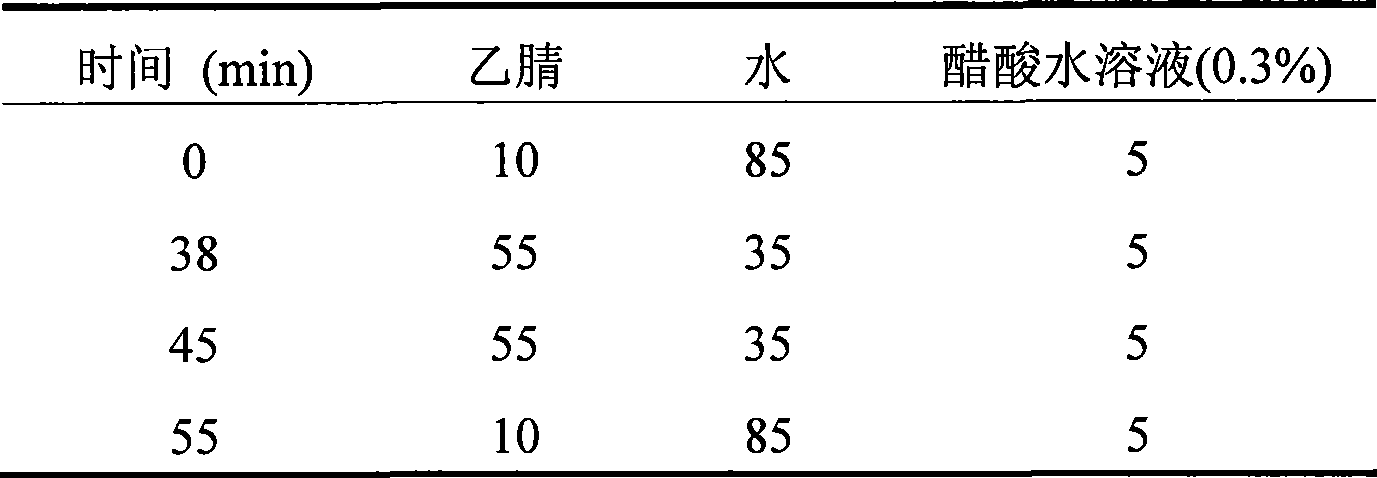

[0025] Add 1000mL of 0.1mol / L NaOH aqueous solution into a 2L three-necked flask with stirring, put it in a constant temperature water bath at 45°C, start stirring, add 5g of asiaticoside raw material in 2 batches (add the second batch after 5h of reaction), and hydrolyze for 24h; Add hydrochloric acid to the hydrolyzate, adjust the pH value to 2-4, filter after precipitation to obtain a precipitate, dry the precipitate and weigh it to obtain 2.4g; collect the dried precipitate and add 24mL ethanol to dissolve, filter, add 144mL water to the filtrate Crystallized, filtered to obtain crystals, and then vacuum-dried to obtain 1.2 g of asiatic acid product, the product was analyzed by HPLC with a mass content of 90.5% asiatic acid and a yield of 45.2%.

Embodiment 2

[0027] Add 1000mL of 0.1mol / L KOH aqueous solution into a 2L three-necked flask with stirring, put it in a constant temperature water bath at 90°C, start stirring, add 10g of asiaticoside raw material in 3 batches (the total feeding time is 30min), hydrolyze for 2h; Add hydrochloric acid to the solution, adjust the pH value to 2-4, filter after precipitation to obtain a precipitate, and weigh the precipitate to obtain 5.0g after drying; add 100mL methanol to dissolve the collected dry precipitate, filter, add 700mL water crystallization to the filtrate , obtained crystals after filtration, and then vacuum-dried the crystals to obtain 3.0 g of asiatic acid product, the product was analyzed by HPLC with a mass content of 91.5% of asiatic acid and a yield of 59.6%.

Embodiment 3

[0029] Add 0.1mol / L Na to a 2L stirred three-neck flask 2 CO 3 Put 1000mL of aqueous solution into a constant temperature water bath at 80°C, start stirring, add 15g of asiaticoside raw material in 4 batches (the total feeding time is 1.5h), and hydrolyze for 6h; add sulfuric acid to the hydrolyzate, adjust the pH value to 2-4, After the precipitation, filter to obtain a precipitate, which is weighed after drying to obtain 7.3g; collect and dry the precipitate and add 292mL of ethanol to dissolve and filter, add 2336mL of water to the filtrate to crystallize, obtain a crystal after filtration, and then pass through After vacuum drying, 4.1 g of asiatic acid product was obtained. The mass content of asiatic acid was analyzed by HPLC to be 90.8%, and the yield was 54.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com