High-content water-dispersion granula and preparation method thereof

A technology of disperse particles and high content, applied in the fields of botanical equipment and methods, biocides, animal repellents, etc., can solve the problems of disintegration, dispersibility, suspension rate, quality index decline, easy particle agglomeration, and performance impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

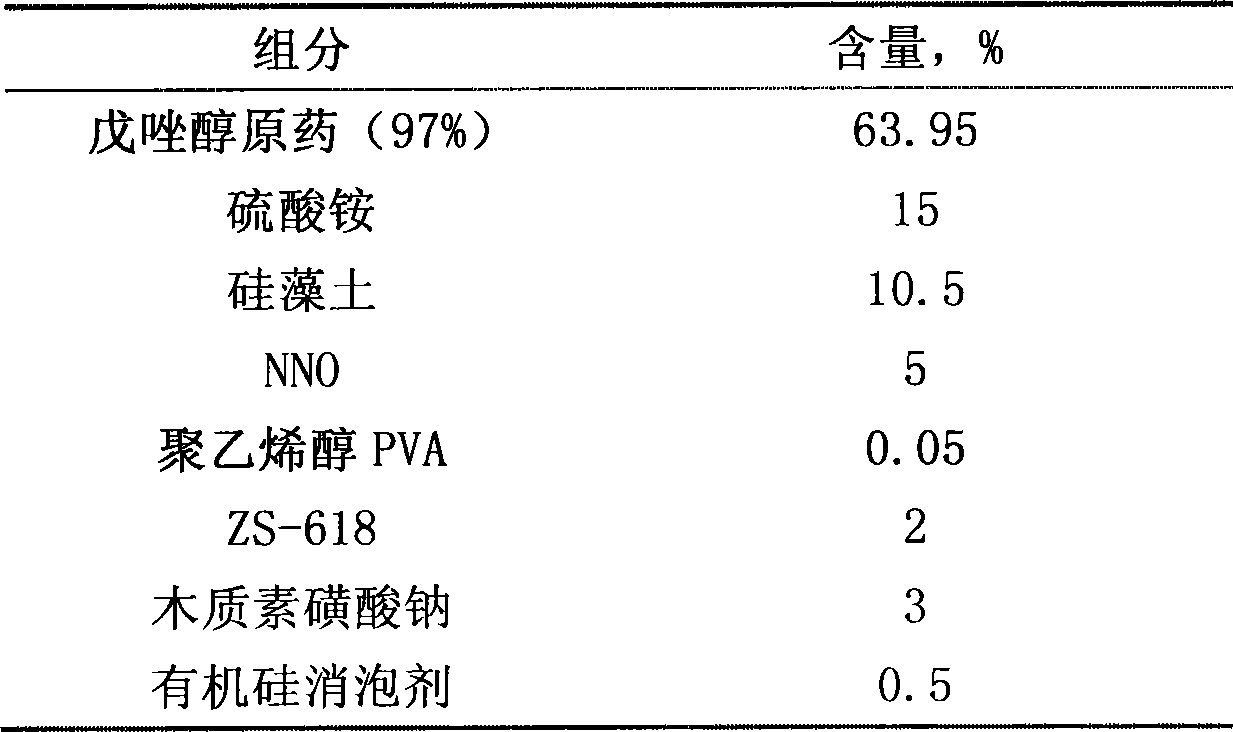

Embodiment 1

[0039] Firstly, the pulverized tebuconazole original drug (with particle size controlled at 5 μm to 15 μm) was mixed with NNO (naphthalene sulfonate formaldehyde condensate), sodium lignosulfonate, ZS-618 (EO / PO block polymer of Zhongshan Chemical Company) Ether), disintegrant ammonium sulfate, filler diatomaceous earth, silicone antifoaming agent are fully mixed, then add 10% of the total weight of the above mixture containing an aqueous solution containing binder polyvinyl alcohol PVA for kneading, and then through disc extrusion Press and granulate, then boil and dry to remove water, sieve, pack, and finally make the finished product.

[0040] The above-mentioned consumption (percentage weight, summation 100%) of each raw material except water is:

[0041]

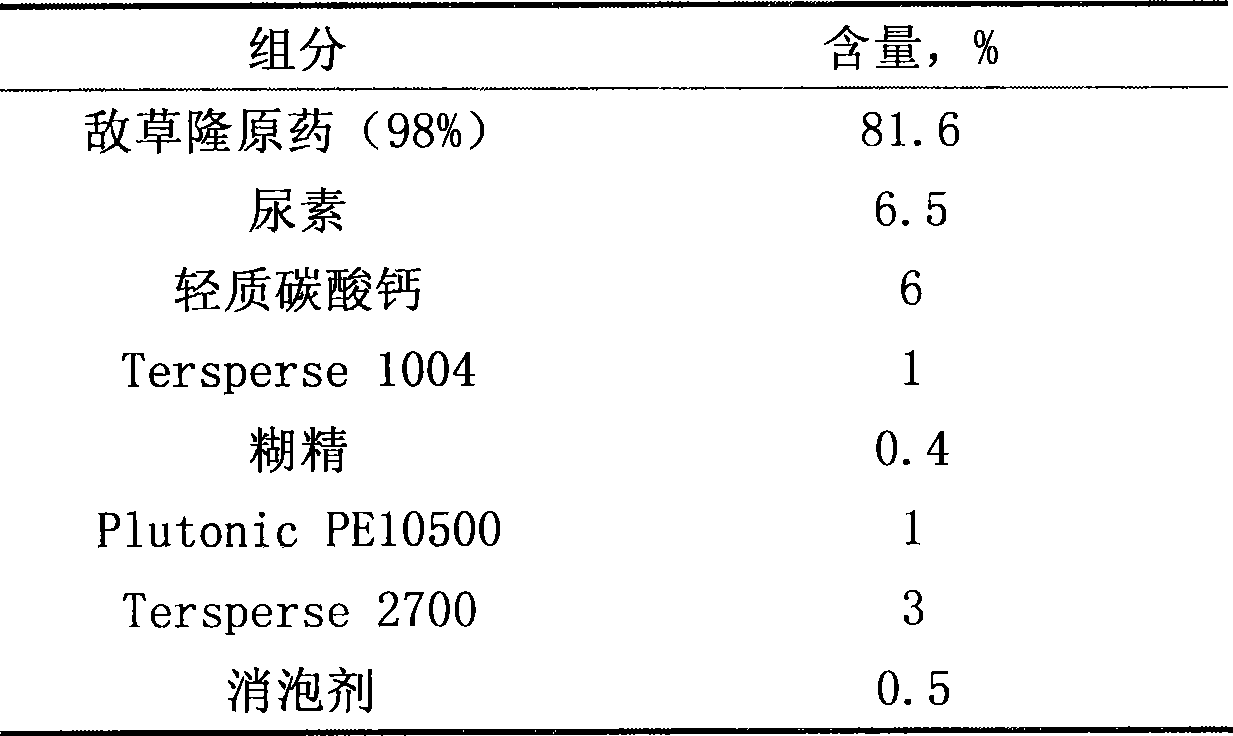

Embodiment 2

[0043] First, the pulverized Diuron technical (particle size controlled at 2 μm to 15 μm) was mixed with wetting Tersperse 1004 (product of Huntsman Company), dispersant Tersperse 2700 (carboxylate product of Huntsman Company), Plutonic PE10500 (EO / PO block polyether), disintegrant urea, filler light calcium carbonate, low-carbon alcohol defoamer are fully mixed, then add the aqueous solution containing binder dextrin that accounts for 15% of the above-mentioned mixture gross weight and knead, and then After disc extrusion granulation, boiling drying, sieving, packaging, and finally the finished product.

[0044] The above-mentioned consumption (percentage weight, summation 100%) of each raw material except water is:

[0045]

Embodiment 3

[0047] First, mix the pulverized imidacloprid original drug (with a particle size of 2 μm to 10 μm) with K12 (sodium lauryl sulfate), sodium lignosulfonate, and dispersant DY-04 (polycarboxylates from Beijing Guangyuan Yinong Company) product), ZS-614 (EO / PO block polyether of Zhongshan Chemical Company), disintegrant ammonium sulfate, filler white carbon black, defoamer, silicone defoamer are fully mixed, and then add the total weight of the above mixture The 12% aqueous solution containing the binder polyethylene glycol PEG-600 is kneaded, then granulated by disc extrusion, then boiled, dried, sieved, packaged, and finally a finished product is obtained.

[0048] The above-mentioned consumption (percentage weight, summation 100%) of each raw material except water is:

[0049]

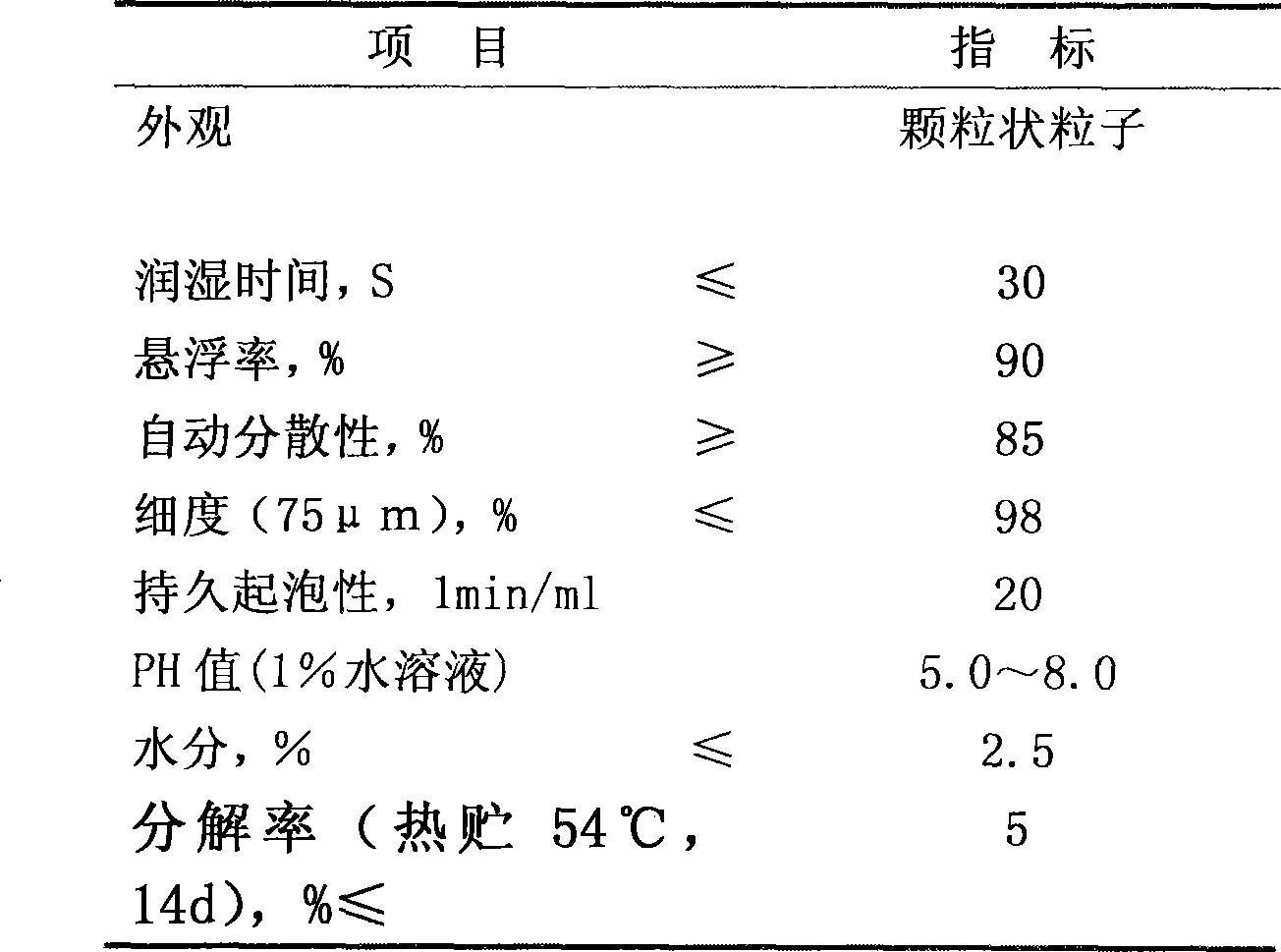

[0050] Main technical indicators of the present invention are as follows:

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com