Pretreatment method for hard solder on partial surface of magnesite product

A local, brazing technology, applied in the direction of welding medium, welding equipment, metal material coating process, etc., can solve the problems of segregation, deformation of magnesium alloy, and corrosion of magnesium alloy by flux without consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

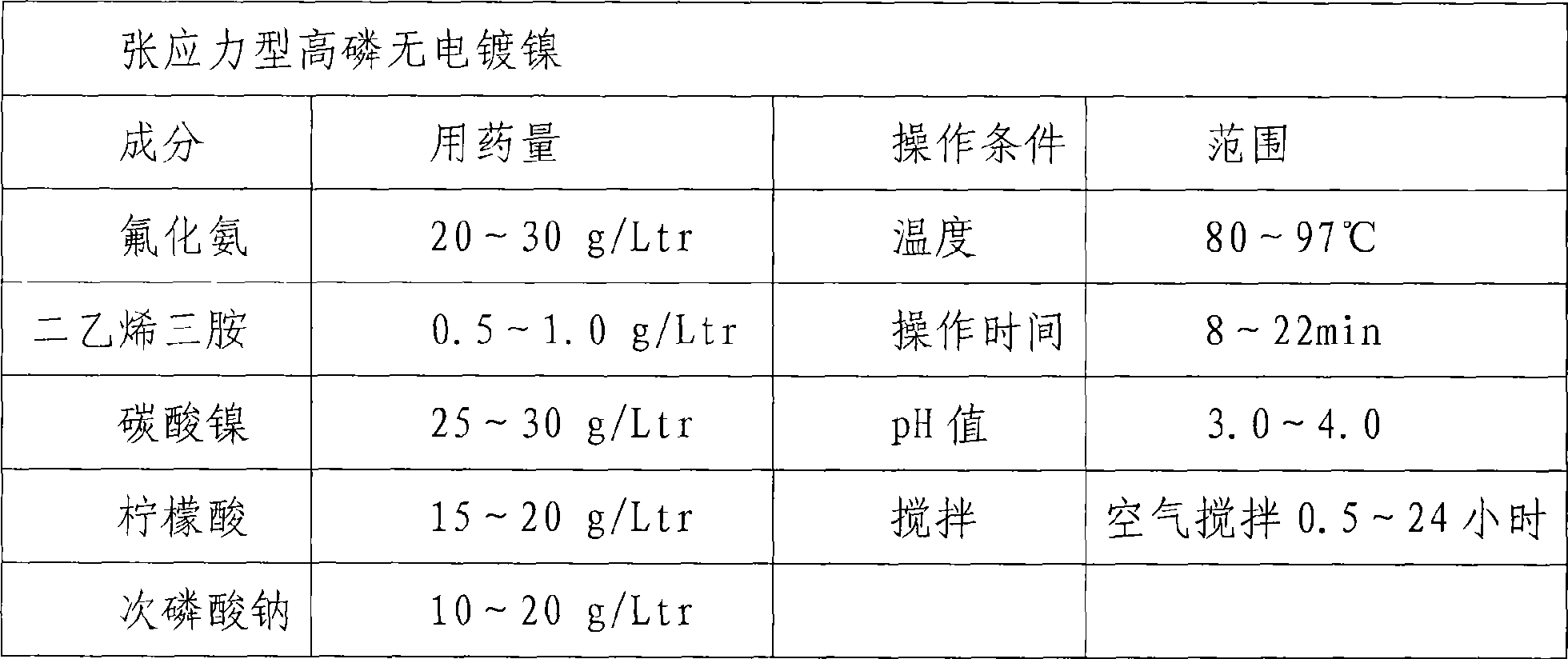

[0011] Magnesium alloy AZ31 plate test piece, thickness 0.4mm, after hot-rolled forming, try to weld copper nut with 3mm outer diameter on it. For example, the process shown in example 1 of patent application No. 095117849 is carried out to the first electroless nickel plating process (the plate test piece at this stage is referred to as test piece A), and it is directly put into the operating conditions without washing with water, as shown in Table 1. The electroless nickel deposition process is carried out in the high-phosphorus electroless nickel plating tank shown (the plate test piece at this stage is referred to as test piece B).

[0012] Table 1: High Phosphorus Electroless Nickel Plating Operating Conditions

[0013]

[0014] Prepare commercial soldering flux (Alpha 100T2) quenched and tempered as shown in Table 2 and mix corresponding tin alloy particles to form solder paste with different components. After reflow shown in Table 2, solder the nut on the magnesium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com