Full-flow process for upgrading and reconstructing urban sewage factory

A technology for upgrading and transformation of urban sewage, applied in the field of urban sewage treatment and recycling, it can solve the problem that the effluent cannot meet the quality of reclaimed water, and achieve the effect of reducing physical indicators such as turbidity and chromaticity, low investment and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The original domestic sewage, secondary effluent, deep effluent and deep removal rate of the sewage plant are shown in Table 1.

[0017] The specific operating parameters are described as follows:

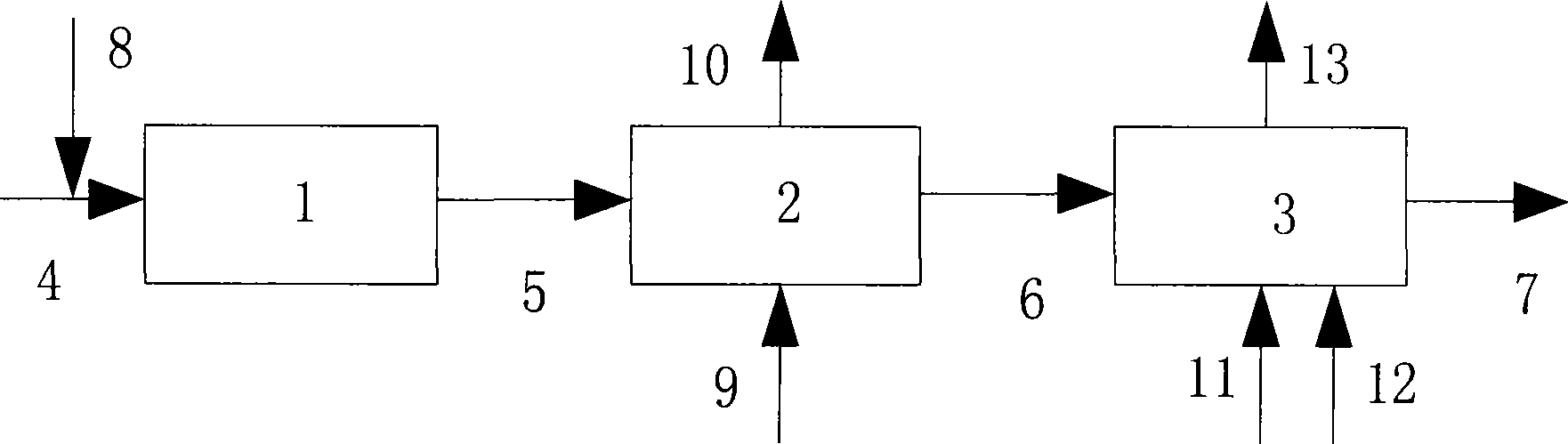

[0018] refer to figure 1 , the secondary effluent of the sewage plant enters the flocculation tank 1 through the water inlet pipe 4, and at the same time, polyaluminum chloride flocculant is added through the flocculant dosing pipe 8. According to the water quality of the secondary effluent in Table 1, the flocculant dosage is 70mg / L. The secondary effluent and flocculant are mixed and reacted in the pipeline mixer, and the flocculation reaction occurs under the third-stage stirring in the flocculation tank, and the stirring intensity is 50 / 30 / 20 (S -1 ), the reaction residence time is 20min. After flocculation, impurity particles, sludge fragments, organic matter, etc. in the water destabilize and aggregate to form a floc combination, and then flow to the air flotation ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com