Apparatus for implementing non-mask surface plasma interference photolithography by using Lloyd lens

A surface plasmon and interference lithography technology, applied in the field of nanofabrication, can solve the problems of increased production cost, high production cost, small processing area, etc., and achieves the effects of high work efficiency, low cost and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. But the following examples are only limited to explain the present invention, and the protection scope of the present invention should include the whole content of claim, and promptly can realize the whole content of claim of the present invention to those skilled in the art through following embodiment.

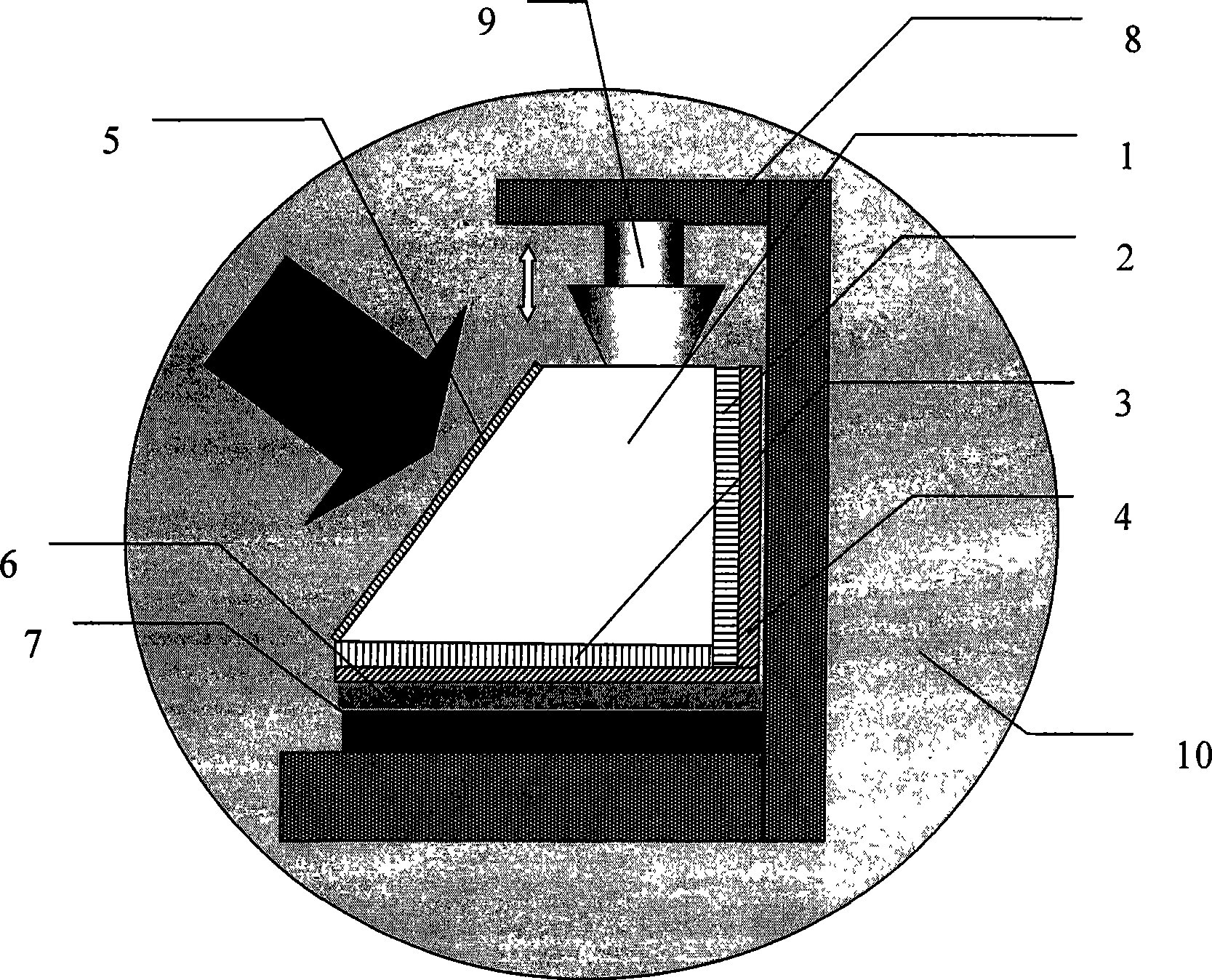

[0028] A device for realizing maskless surface plasmon interference lithography using a Lloyd mirror in this embodiment, its structural schematic diagram is as follows figure 1 As shown; including: a precision turntable 10 for adjusting the angle of incident light; a right-angled trapezoidal prism 1 for coupling excitation surface plasmon interference; a pressing device 9 for pressing the substrate 7 and the right-angled trapezoidal prism 1; Fix the support 8 of the pressing device 9 .

[0029] The right-angled trapezoidal prism in the devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com