Ozagrel sodium microballoon lyophilized preparation and preparation method thereof

A technology of ozagrel sodium and freeze-dried agent, which is applied in the field of medicine, can solve problems such as short storage time, clarity problems, suspended particles, etc., and achieve the effect of simple process, low production cost and good targeting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

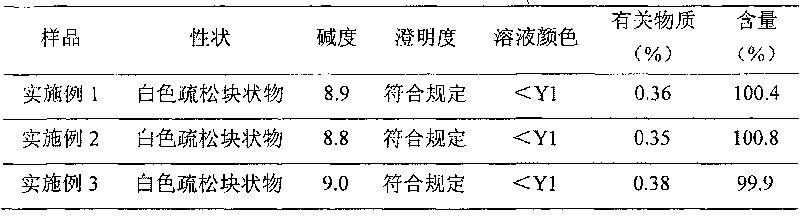

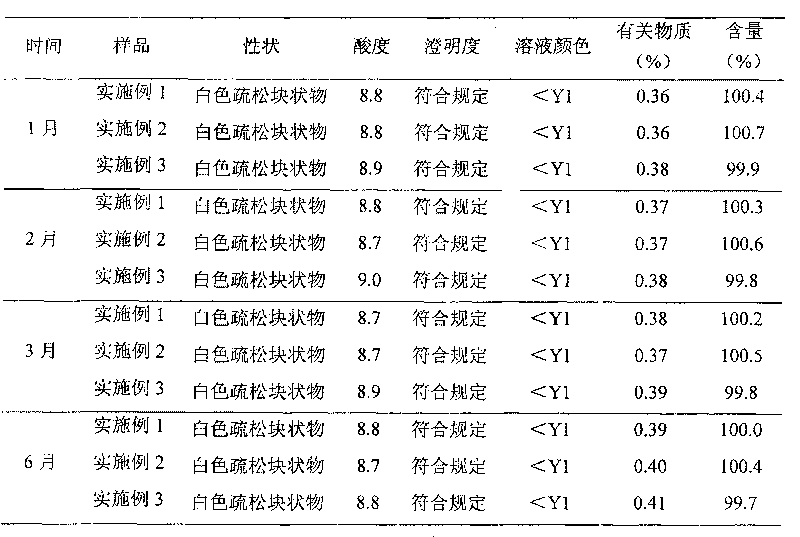

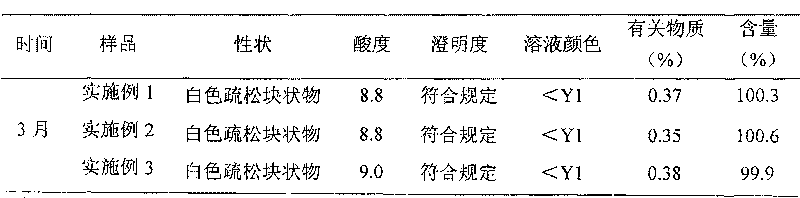

Embodiment 1

[0034] The composition of the freeze-dried agent:

[0035] Component Content

[0037] Chitosan 50g

[0038] Polyvinyl alcohol 1500 40g

[0039] Polysorbate 80 30g

[0040] Glucose 50g

[0041] Preparation:

[0042] (1) Dissolve 40g of polyvinyl alcohol 1500 in 500ml of distilled water, then add 30g of polysorbate 80, stir to dissolve completely, and obtain the water phase;

[0043] (2) 20g sodium ozagrel and 50g chitosan are dissolved in 500ml ethanol together, stir well, obtain oily phase;

[0044] (3) Slowly add the oil phase to the water phase, and keep stirring, the solution temperature is kept at 55°C, the oil phase rapidly diffuses into the water phase, forming an O / W or W / O emulsion;

[0045] (4) Heat the obtained emulsion to 80° C. under magnetic stirring, remove ethanol to obtain a suspension, centrifuge for 15-30 min, wash with distilled water to remove organic solvent and surfactant residues, and obtain microsphere precipitates;

...

Embodiment 2

[0048]The composition of the lyophilizer:

[0049] Component Content

[0051] Chitosan 150g

[0052] Polyvinyl alcohol 1500 100g

[0053] Poloxamer 188 120g

[0054] Mannitol 300g

[0055] Preparation:

[0056] (1) dissolve 100g polyvinyl alcohol 1500 in 1000ml distilled water, add 120g poloxamer 188 again, stir and dissolve completely, obtain water phase;

[0057] (2) co-dissolving 80 g of sodium ozagrel and 150 g of chitosan in 1000 ml of n-hexane, stirring evenly to obtain an oil phase;

[0058] (3) slowly adding the oil phase to the water phase, and stirring continuously, the solution temperature was maintained at 70°C, and the oil phase quickly diffused into the water phase to form an O / W or W / O type emulsion;

[0059] (4) heating the obtained emulsion to 80°C under magnetic stirring, removing n-hexane to obtain a suspension, centrifuging for 15 to 30 min, and washing with distilled water to remove organic solvent and surfactant residue ...

Embodiment 3

[0062] The composition of the lyophilizer:

[0063] Component Content

[0064] Sodium Ozagrel 40g

[0065] Chitosan 100g

[0066] Polyvinyl alcohol 2000 60g

[0067] Polysorbate 80 100g

[0068] Sorbitol 180g

[0069] Preparation:

[0070] (1) dissolve 60g polyvinyl alcohol 2000 in 800ml distilled water, add 100g polysorbate 80 again, stir and dissolve completely, obtain water phase;

[0071] (2) Dissolve 40 g of sodium ozagrel and 100 g of chitosan in 600 ml of ethanol, stir evenly, and it is an oil phase;

[0072] (3) slowly adding the oil phase to the water phase, and stirring continuously, the solution temperature was maintained at 60°C, and the oil phase quickly diffused into the water phase to form an O / W or W / O type emulsion;

[0073] (4) heating the obtained emulsion to 80°C under magnetic stirring, removing ethanol to obtain a suspension, centrifuging for 15 to 30 min, and washing with distilled water to remove organic solvent and surfactant residue to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com