Ion exchange fiber material one-step preparation method

A technology of ion exchange fiber and synthetic fiber, applied in the direction of cation exchange material, ion exchange, anion exchange, etc., can solve the problems of monomer waste, low grafting efficiency, environmental pollution, etc., and achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

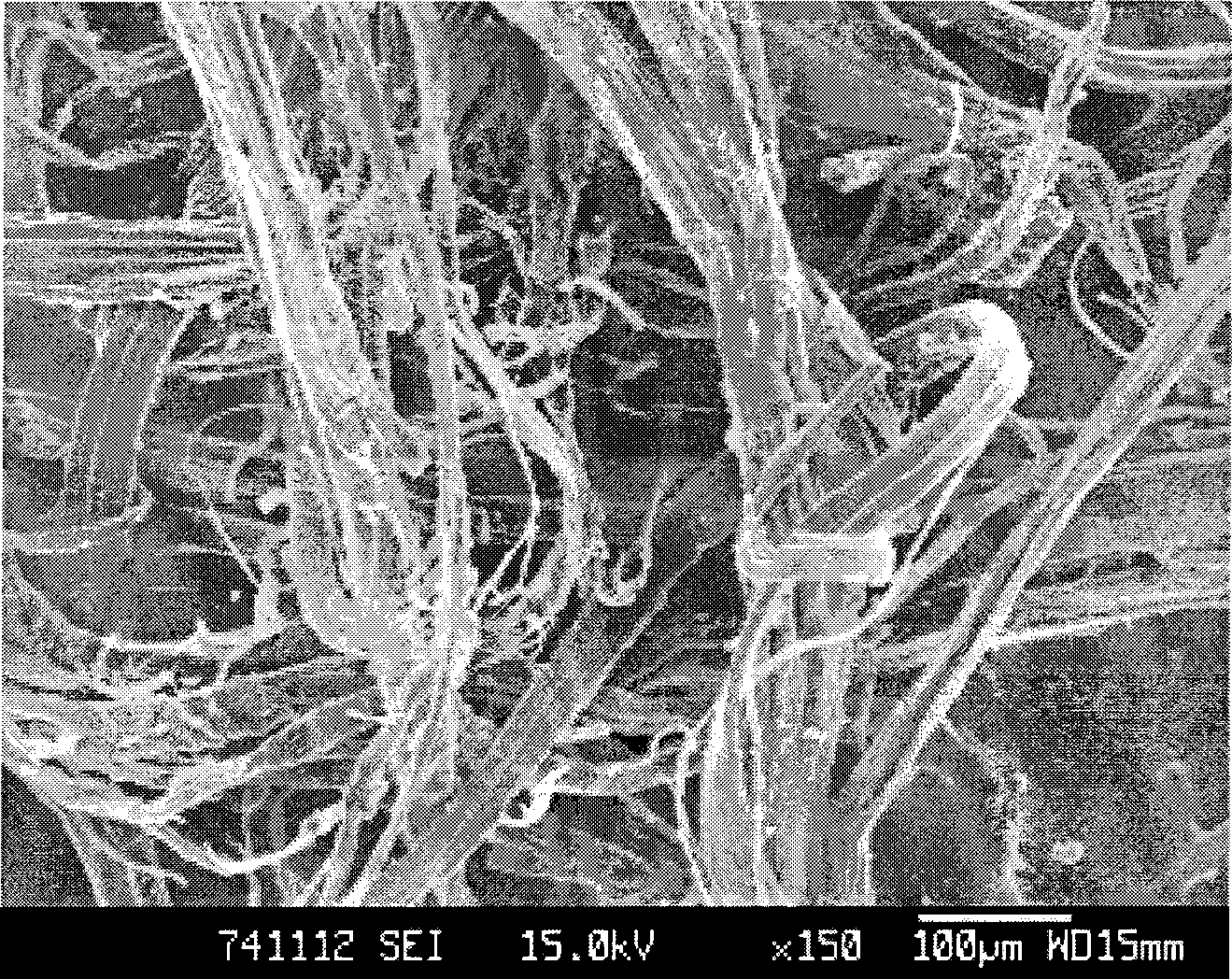

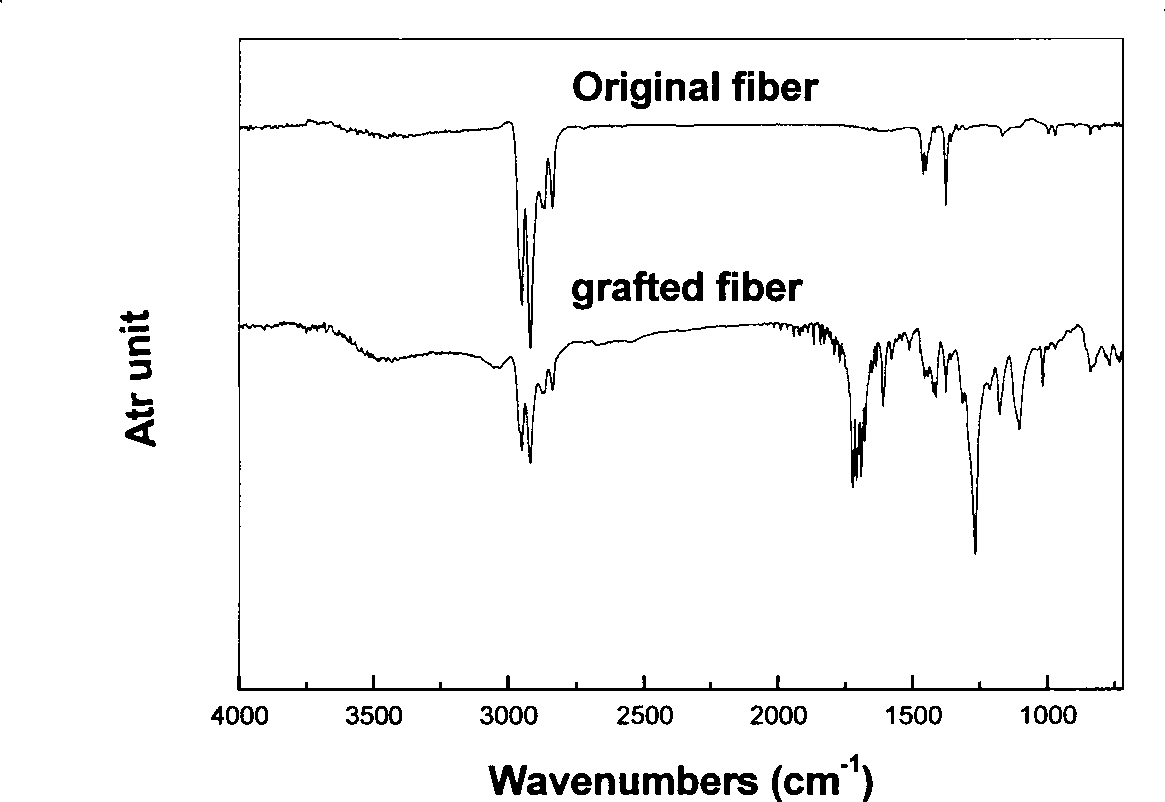

Embodiment 1

[0019] Weigh a certain amount of pretreated polytetrafluoroethylene fiber into a stoppered Erlenmeyer flask, and seal it with a silica gel membrane. It is irradiated with cobalt 60 gamma rays, the radiation dose is controlled to 48KGy, and the irradiation time is 55 hours. Sodium sulfonate styrene, acrylic acid monomer (monomer ratio: 1:3) and dichloromethane were prepared into a homogeneous mixed solution at a volume percentage of 60:40, and added at a bath ratio of 1:30 (weight: volume) 3.5g pre-irradiated polytetrafluoroethylene fiber, add activator Mohr's salt by 5%, react at 80 DEG C for 6 hours, remove organic solvent and unpolymerized monomer by vacuum distillation of grafting system after reaction, The calculated monomer conversion rate was 95%, soaked in toluene for 2 days, removed the homopolymer by suction filtration, washed with methanol, and dried in vacuum. The calculated graft rate was 167%, and the graft efficiency was 10.4%. Transform the fiber material with ...

Embodiment 2

[0021] Weigh a certain amount of pretreated polytetrafluoroethylene fiber into a stoppered Erlenmeyer flask, and seal it with a silica gel membrane. It is irradiated with cobalt 60 gamma rays, the radiation dose is controlled to 48KGy, and the irradiation time is 55 hours. Sodium sulfonate styrene, acrylic acid monomer (monomer ratio: 1:3) and N, N-dimethylformamide are prepared into a homogeneous mixed solution at a volume percentage of 60:40, with a bath ratio of 1:30 (weight:volume) 3.5 g of pre-irradiated polytetrafluoroethylene fiber was added, activator mohr salt was added at 5%, the reaction temperature was 75° C., and the reaction time was 8 hours. Subsequent treatment was the same as in Example 1, and the same type of ion exchange fiber material was obtained, the monomer conversion rate was 98%, the grafting rate was 120%, and the grafting efficiency was 7.5%. The maximum static exchange capacity is 3.0mmol / g, of which the strong acid part is 1.85mmol / g.

Embodiment 3

[0023] Weigh a certain amount of pretreated polyacrylonitrile fiber into a stoppered Erlenmeyer flask, and seal it with a silica gel membrane. It is irradiated with cobalt 60 gamma rays, the radiation dose is controlled to 48KGy, and the irradiation time is 55 hours. Sodium sulfonate styrene, acrylic acid monomer (monomer ratio: 1:5) and dichloromethane were prepared into a uniform mixed solution at a volume percentage of 50:50, and added at a bath ratio of 1:30 (weight: volume) 3.5g pre-irradiated polyacrylonitrile fiber, add activator nano-magnesium powder by 5%, react at 80°C for 6 hours, remove organic solvent and unpolymerized monomer by vacuum distillation of the graft system after reaction, calculate The conversion rate of the monomer is 96%. Soak in toluene for 2 days, remove the homopolymer by suction filtration, wash with methanol, and dry in vacuum. The calculated grafting rate is 133%, and the grafting efficiency is 9.79%. Transform the fiber material with 1M hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com