Anti-caking agent for mineral composite fertilizer and production method and use thereof

The technology of an anti-caking agent and a manufacturing method is applied in the directions of application, fertilization device, fertilizer mixture, etc., and can solve the problems of applicable soil and surrounding environment pollution, low particle forming strength, and difficulty in improving soil, etc. The effect of protecting soil and facilitating crop absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Raw material ingredients according to the following weight and physical index requirements:

[0033] 1. Use pure natural high-quality talc (telc): 80%; physical index requirements: whiteness ≥ 90%, refractive index: 1.57, dry brightness 85-92%, average particle size 0.25-0.5 μm, relative density 2.70-2.75, Oil-absorbing base 25-35ml / 100g, silicon dioxide content ≥ 61%, magnesium oxide content ≥ 31%;

[0034] 2. Potassium feldspar (KAlSi308): 10%; physical index requirements: K2O.Al2O3.6SiO2 of which K2O 9.55%, Al2O3 above 16%, SiO2 70%, density 2.56g / cm 3 , Mohs hardness: 6, monoclinic crystal system, the color is white, milky white,

[0035] 3. Attapulgie CIay: 5%, physical index requirements: mg023.8% siO 2 52.96%H 2 O19.21%, Mohs hardness 2-3, specific gravity 2.05-2.32; attapulgite clay has cation exchangeability, all kinds of attapulgite clay can exchange calcium ions of 7.5-12.5mmol / 100g, and can exchange magnesium The ion content is 2.5~7.5mmol / 100g. After a...

Embodiment 2

[0039] Raw material batching by following weight ratio:

[0040] Excellent grade talc (telc): 90%; potassium feldspar (KAlSi308): 5%; natural pure white purified attapulgite (Attapulgie CIay) 5%.

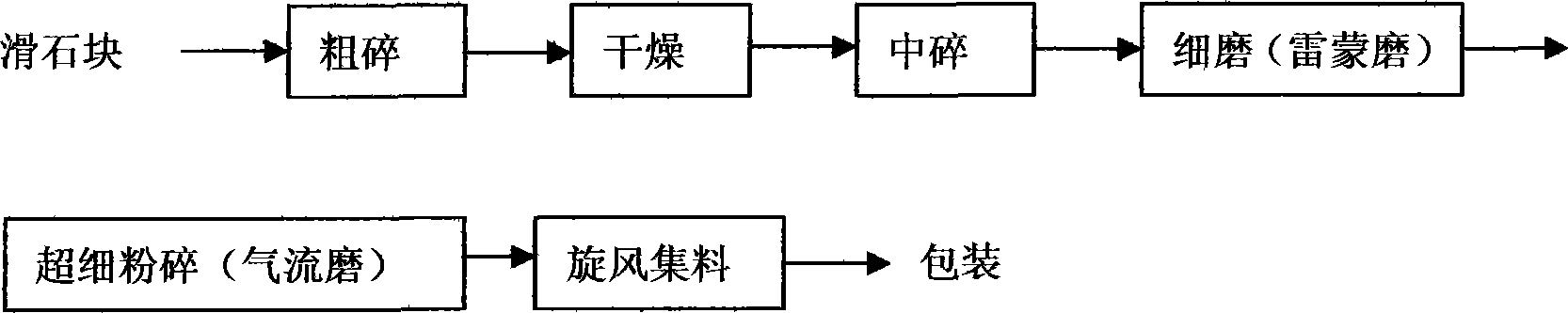

[0041] The talc is crushed by dry process, such as figure 1 . Production process: firstly, the screened talc is sent to the hammer crusher for crushing by the feeder; the crushed material enters the Raymond mill for fine grinding through the bucket elevator and vibrating feeder; the finely ground The talcum powder enters the jet mill for ultra-fine crushing, and is collected by a cyclone collector. The final product fineness can reach 500-5000 mesh (d 97 =30-5um). The calcining temperature of talc is 600-1200℃, and the potassium feldspar and attapulgite after mineral processing and purification are respectively crushed to 2-10 microns, and then finely classified to 500-2500 mesh; then the potassium feldspar, attapulgite Put the rod stones into a continuous vortex powder surface mo...

Embodiment 3

[0043] Raw material batching by following weight ratio:

[0044] Use pure natural high-grade talc: 85%; potassium feldspar (KAlSi308): 10%, illite: 5%.

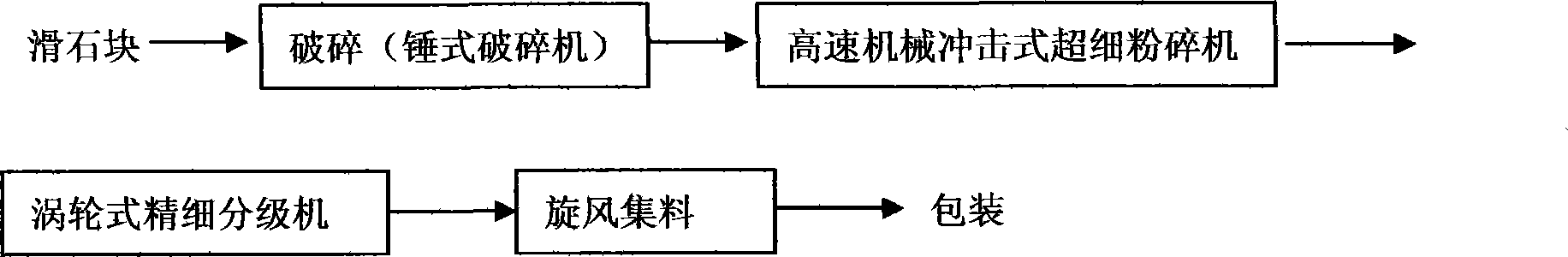

[0045] Production process: the high-speed mechanical impact ultra-fine powder ore process of talc is as follows: figure 2 . First, the selected high-quality talc blocks are crushed to 8mm by a hammer crusher, and then directly fed into a high-speed mechanical impact ultrafine pulverizer. The pulverized products are classified by a turbine fine classifier and collected by a cyclone collector. The coarse-grained products after classification can be returned to the mill or used as products alone; the modification mainly adopts dry modification process; it is calcined in a continuous vortex powder surface modification machine (SLG type). The calcining temperature is generally 600-1200°C. Within this temperature range, the higher the temperature, the higher the whiteness of the calcined talc, and the calcined whiteness can reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com