Method for preparing silicon base mesoporous molecular sieve SBA-15 immobilized enzyme biocatalyst

A biocatalyst and silicon-based mesoporous technology, which is applied in the direction of immobilization on/in the organic carrier, can solve the problems of easy leakage of immobilized enzymes, unsuitable catalysis of macromolecular substrate reactions, diffusion limitations, etc., and achieve the preparation process Simple and reliable, good enzyme dispersion, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

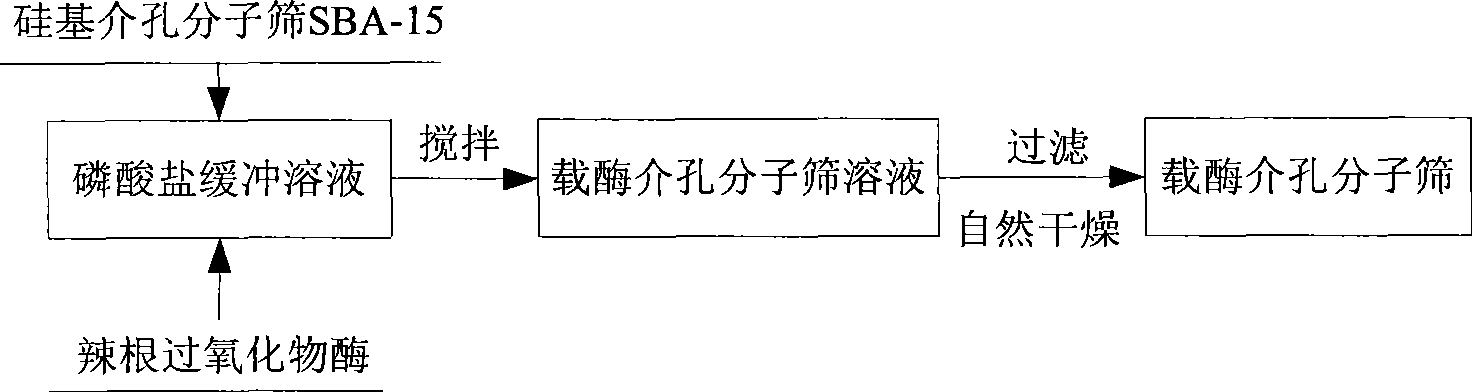

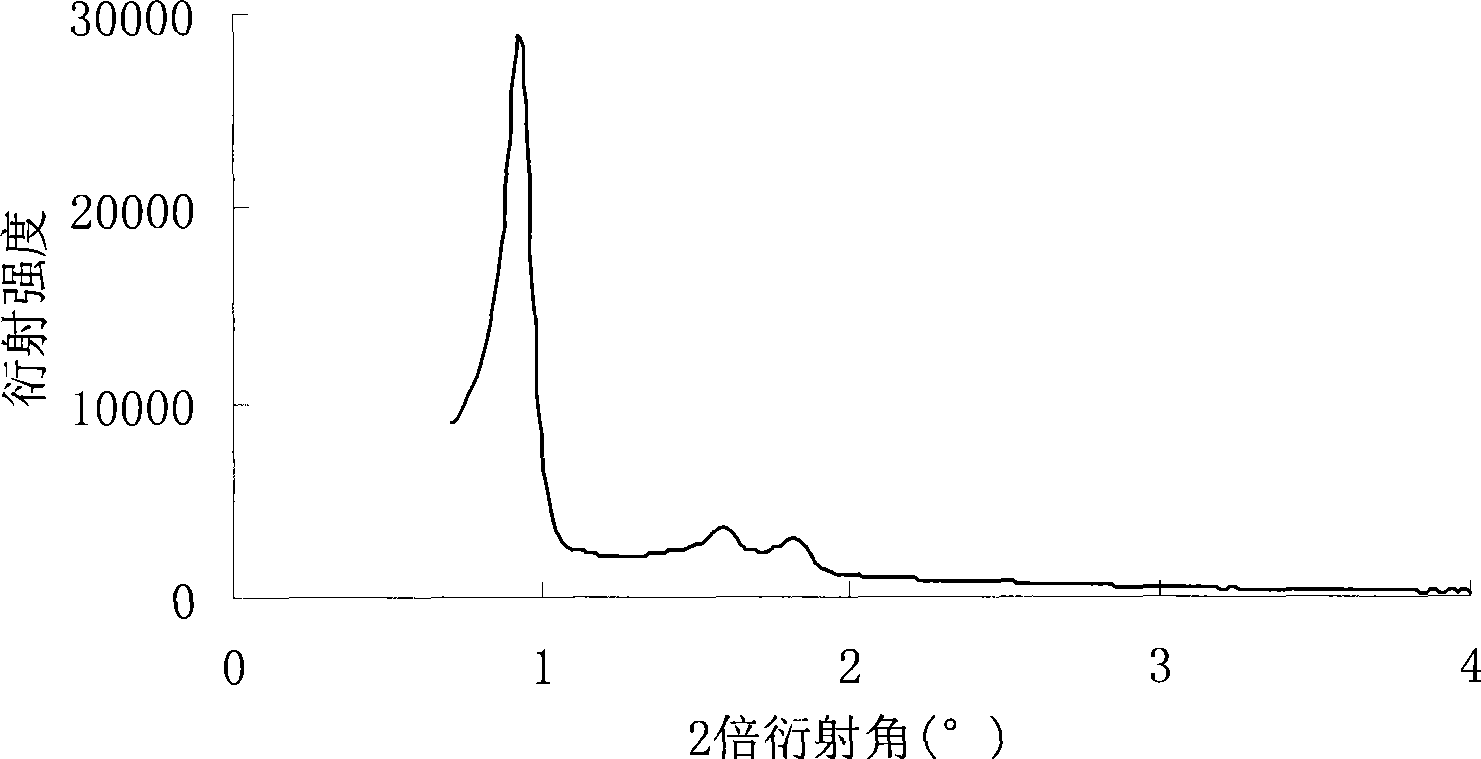

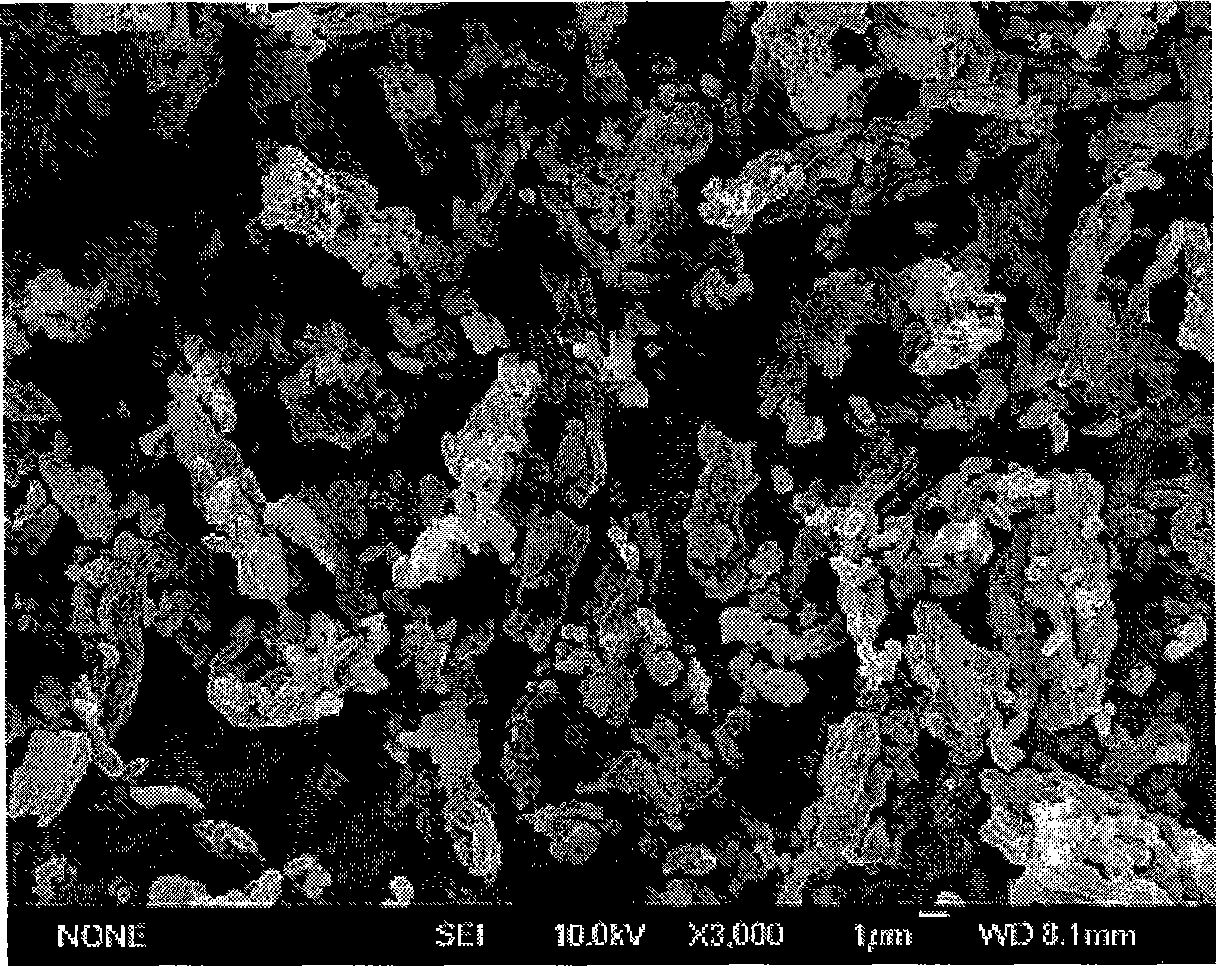

[0024] See attached figure 1 process flow chart. Firstly, the mesoporous molecular sieve SBA-15 carrier was prepared. Polyoxyethylene ether-polyoxypropylene ether-polyoxyethylene ether triblock copolymer (P123) was used as a template, and tetraethyl orthosilicate (TEOS) was used as a silicon source. Weigh 2.0g of P123 into a beaker, add 15g of water and 60g of 2M hydrochloric acid solution, stir at 35°C until P123 is completely dissolved, then add 4.25g of TEOS, and keep stirring at 35°C for 20h. Subsequently, the reactant was transferred to a polytetrafluoroethylene-lined reactor and reacted at 80°C for 24 hours. Finally, the solid product was collected, washed with water, dried at room temperature, and the temperature was slowly raised to 500° C. within 8 hours, and calcined at a constant temperature for 6 hours. The calcined powder is SBA-15 with channels. The prepared SBA-15 has a pore size of about 6.7nm and a specific surface area of 686m 2 / g, the specific pore v...

Embodiment 2

[0028] Step a in this example is the same as step a in Example 1; then add 0.2 g of the prepared silicon-based mesoporous molecular sieve SBA-15 carrier to 15 ml of disodium hydrogen phosphate-dihydrogen phosphate with an adsorption reaction pH of 8 Sodium buffer solution, placed on a magnetic stirrer and stirred for 1h to disperse evenly in the solution. After stirring, 1 mg, 2 mg, 4 mg, 6 mg, 8 mg, and 10 mg of horseradish peroxidase were added into the solution and stirred, and the adsorption reaction time was 6 hours. Then filter, wash the molecular sieve material alternately and repeatedly with secondary water and phosphate buffer solution, and finally dry the obtained enzyme-loaded molecular sieve naturally to obtain the immobilized enzyme biocatalyst. attached by Figure 5 It can be seen that, under other conditions being the same, the relative activity of the immobilized enzyme increases as the amount of the enzyme increases. When the amount of the enzyme per gram of ...

Embodiment 3

[0030] Step a in this example is the same as step a in Example 1; then add 0.2 g of the prepared silicon-based mesoporous molecular sieve SBA-15 carrier to 15 ml of disodium hydrogen phosphate-dihydrogen phosphate with an adsorption reaction pH of 8 Sodium buffer solution, placed on a magnetic stirrer and stirred for 1h to disperse evenly in the solution. After the stirring is completed, 4 mg of horseradish peroxidase is added into the solution and stirred, and the adsorption reaction time is 1 h, 2 h, 3 h, 4 h, 5 h, 6 h, 7 h, 8 h. Then filter, wash the molecular sieve material alternately and repeatedly with secondary water and phosphate buffer solution, and finally dry the obtained enzyme-loaded molecular sieve naturally to obtain the immobilized enzyme biocatalyst. attached by Figure 6 It can be seen that the relative enzyme activity of the immobilized enzyme increases with the increase of the adsorption time. When the adsorption time is 4 hours, the relative enzyme activ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com