Solvent-free epoxy coating for long distance pipeline repaired mouth

A technology for long-distance pipelines and epoxy coatings, applied in the direction of epoxy resin coatings, coatings, etc., which can solve the harsh construction requirements of primers and heat shrinkable tapes, the difficulty in guaranteeing the quality of baking bonding, and the lack of outstanding anti-corrosion functions, etc. problems, to achieve the effect of excellent storage stability, excellent constructability, and good peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

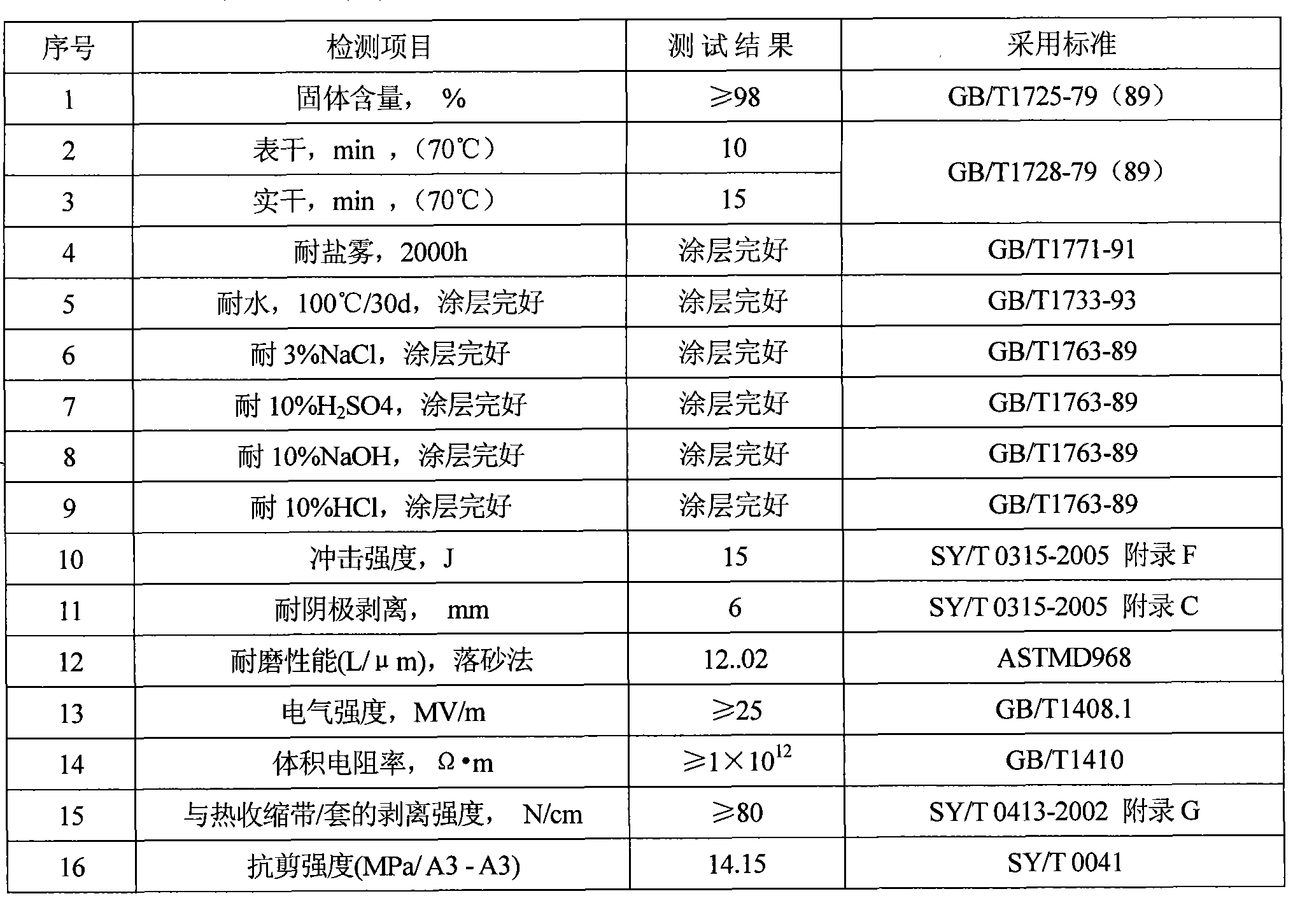

Examples

Embodiment 1

[0013] The invention discloses a method for manufacturing a solvent-free epoxy coating for joint joints of long-distance pipelines. In a stainless steel barrel, add 0.06 parts by weight of polycarboxylic acid solution containing amine derivatives, 0.01 parts by weight of acrylate copolymer, and 0.015 parts by weight of polysilicon in 1 part by weight of bisphenol F epoxy resin. Oxane solution, 0.02 parts by weight of polyether siloxane copolymer, and 0.02 parts by weight of urethane oligomer solution are heated, controlled at 25°C, mixed, and stirred at a high speed. Add the fumed silica powder of 0.025 parts by weight, the carbon black of 0.002 parts by weight, the precipitated barium sulfate of 0.24 parts by weight, the mica powder of 0.2 parts by weight, the quartz powder of 0.2 parts by weight, the silicon carbide of 0.3 parts by weight, the silicon carbide of 0.07 parts by weight 1 part of chromium oxide green, stirred at high speed for 0.25h, and ground it with a sand mi...

Embodiment 2

[0015] The manufacture method of the solvent-free epoxy paint for long-distance pipeline filling of the present invention is characterized in that in the bisphenol F epoxy resin of 1 weight part, successively add the polycarboxylic acid solution of 0.01 weight part containing amine derivative, 0.005 The acrylate copolymer of parts by weight, the polysiloxane solution of 0.005 parts by weight, the polyether siloxane copolymer of 0.005 parts by weight, the urethane oligomer solution of 0.01 parts by weight, it is heated, controlled temperature At 25°C, mix and stir at high speed, add 0.01 parts by weight of fumed silica powder, 0.002 parts by weight of carbon black, 0.1 parts by weight of precipitated barium sulfate, 0.1 parts by weight of mica powder, 0.1 parts by weight of Part of quartz powder, 0.1 part by weight of silicon carbide, 0.01 part by weight of chromium oxide green, after stirring at high speed for 0.25h, grind 0.5 part with a sand mill to make liquid A in the coati...

Embodiment 3

[0017] The manufacture method of the solvent-free epoxy paint for long-distance pipeline repairing of the present invention is characterized in that in the bisphenol F epoxy resin of 1 weight part, add successively the polycarboxylic acid solution containing amine derivative of 0.1 weight part, 0.05 The acrylate copolymer of parts by weight, the polysiloxane solution of 0.05 parts by weight, the polyether siloxane copolymer of 0.05 parts by weight, the urethane oligomer solution of 0.05 parts by weight, it is heated, controlled temperature At 25°C, mix and stir at high speed, add 0.05 parts by weight of fumed silica powder, 0.01 parts by weight of carbon black, 0.5 parts by weight of precipitated barium sulfate, 0.3 parts by weight of mica powder, 0.5 parts by weight of Part of quartz powder, 0.5 parts by weight of silicon carbide, 0.1 parts by weight of chromium oxide green, after stirring at high speed for 0.25h, grind 1h with a sand mill to make liquid A in the coating; in 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com