Method for preparing gallium nitride based field-effect transistor

A gallium nitride-based field and gallium nitride-based technology, which is applied in the field of manufacturing gallium nitride-based field effect transistors, can solve the problems of AlGaN surface pollution and increase of AlGaN surface state density, and achieve surface state elimination, suppression increase, The effect of solving the current collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

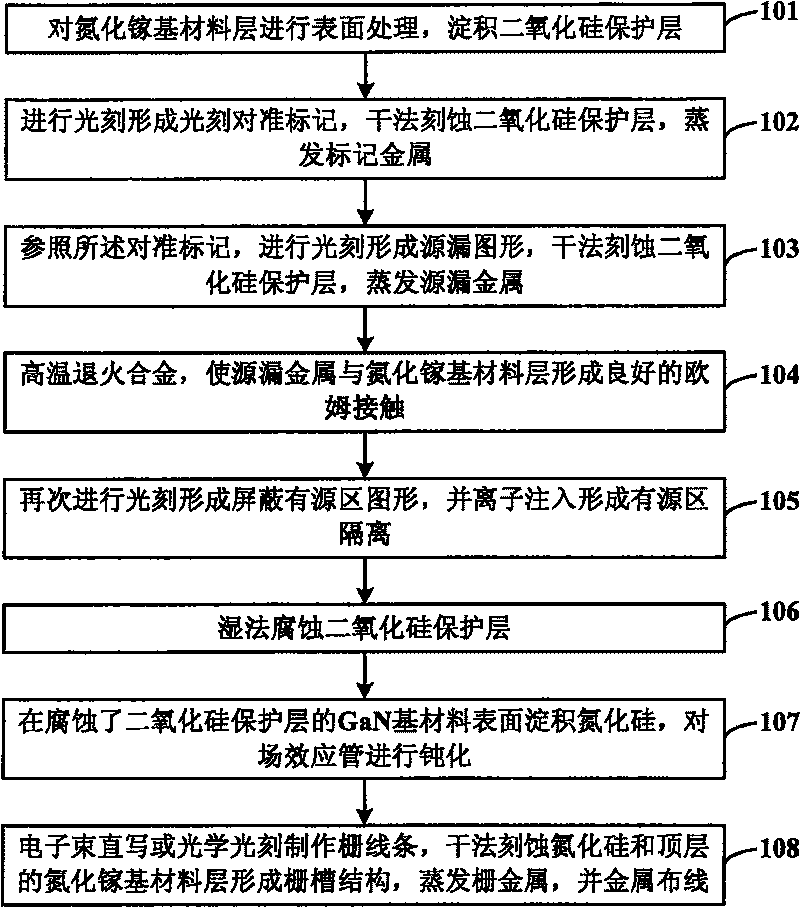

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

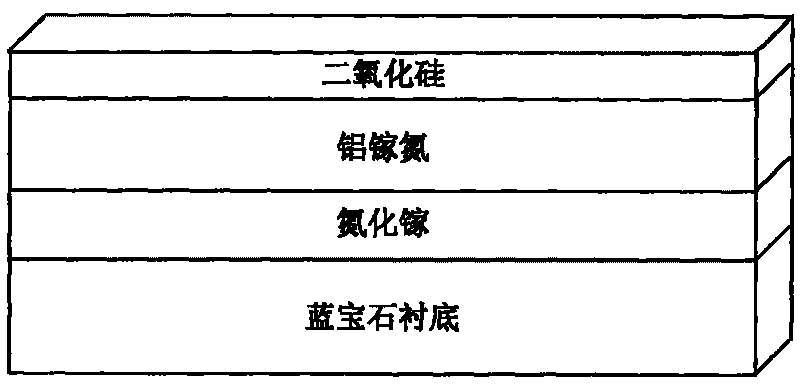

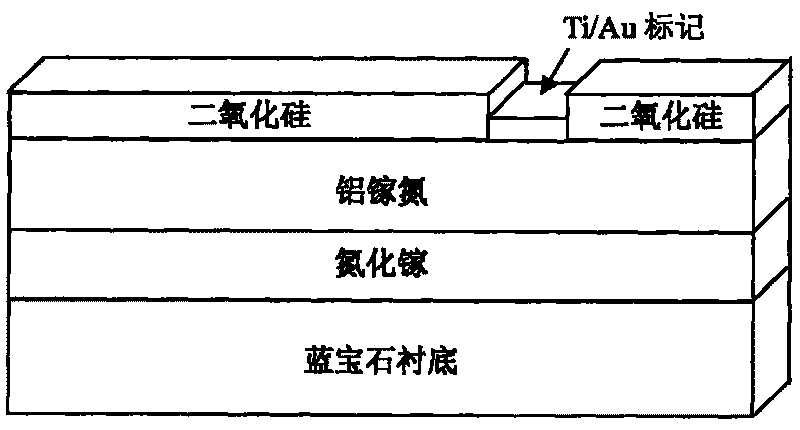

[0048] The core idea of the present invention is to use a mixed solution of acetone, isopropanol, hydrochloric acid and hydrofluoric acid to treat the surface of gallium nitride-based materials, remove surface dirt, corrode the original oxide layer on the surface, and eliminate surface damage caused by the oxide layer. state, which reduces the surface state density of gallium nitride-based materials, and before the HEMT manufacturing process, PECVD is the first to deposit silicon dioxide on gallium nitride-based materials to protect the surface of gallium nitride-based materials and avoid gallium nitride-based materials. The surface of the material is exposed in the air, which prevents the surface of the gallium nitride-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com