Solar cell, front film layer structure of solar cell, preparation method of front film layer structure, assembly and system

A technology of solar cells and film layer structure, applied in the field of solar cells, can solve the problems of poor anti-PID potential induction performance and low conversion efficiency of battery components, and achieves improved compactness and passivation effect, increased absorption and utilization, and increased light. absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

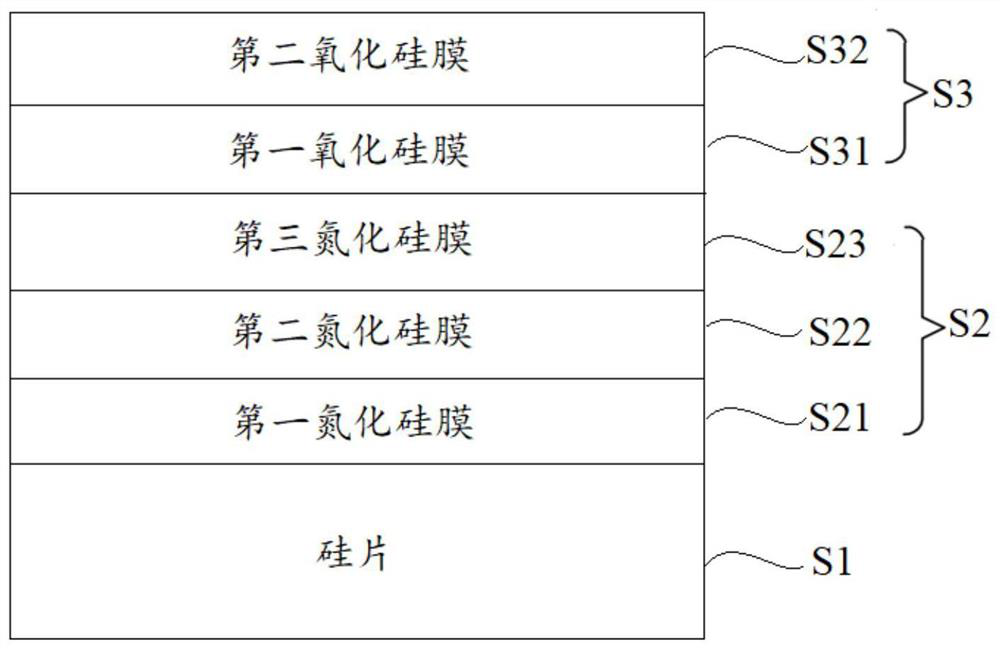

[0052] see figure 1 , is a structural schematic diagram of the front film layer structure of the solar cell provided by the first embodiment of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown. The front film layer of the solar cell provided by the embodiment of the present invention The structure includes a silicon nitride layer S2 and a silicon oxide layer S3 sequentially deposited on the front side of the silicon wafer S1;

[0053] The silicon nitride layer S2 is composed of at least three layers of silicon nitride films with different refractive indices; the silicon oxide layer S3 is composed of at least two layers of silicon oxide films with different refractive indices.

[0054] The refractive index of each layer of silicon nitride film and silicon oxide film arranged in sequence decreases successively.

[0055] Among them, in one embodiment of the present invention, the front film lay...

Embodiment 2

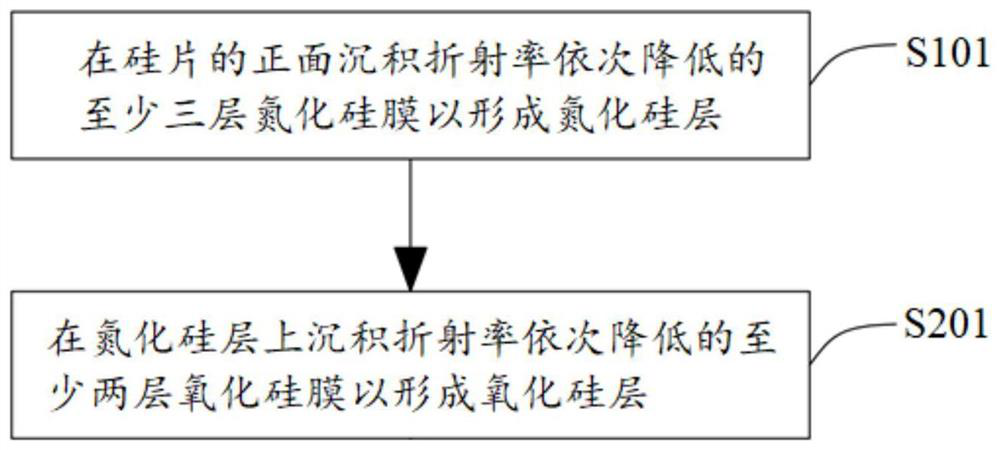

[0070] see figure 2 , is a schematic flow chart of a method for preparing a solar cell front film structure provided by the second embodiment of the present invention. For the convenience of description, only the parts related to the embodiment of the present invention are shown. The front film layer structure of the solar cell of the embodiment, specifically, the method includes:

[0071] Step S11, depositing a silicon nitride layer S2 on the front surface of the silicon wafer S1; depositing at least three layers of silicon nitride films with a gradually decreasing refractive index on the front surface of the silicon wafer to form a silicon nitride S2 composed of multiple layers of silicon nitride films layer;

[0072] Among them, in the embodiment of the present invention, a single crystal silicon wafer is selected, which is processed into a silicon substrate required for deposition after sequential texturing, diffusion, SE laser, etching, and annealing treatments, specifi...

Embodiment 3

[0105] The third embodiment of the present invention also provides a solar cell, which includes a silicon wafer, a back film structure deposited on the back of the silicon wafer, and a front film structure as in the preceding embodiment deposited on the front of the silicon wafer.

[0106] This embodiment provides a solar cell with high performance and high reliability. By setting at least three silicon nitride layers and at least two silicon oxide film layers in the front film system, compared with the existing front film structure, A layer of silicon nitride film and silicon oxide film is added to increase the absorption of short-wavelength light and reduce the reflection of light back to the incident interface to reduce the reflection loss of light on the front side, thereby increasing the absorption and utilization of light by silicon wafers and improving solar cells. The conversion efficiency of the front side is increased by more than 0.05%; through the cooperation of at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com