Modified rare-earth-containing molecular sieve catalyst as well as preparation method and use thereof

A molecular sieve and catalyst technology, applied in the field of low-carbon olefin catalysts and their preparation, can solve the problems of low propylene selectivity, short catalyst life, low methanol conversion rate, etc., and achieve the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

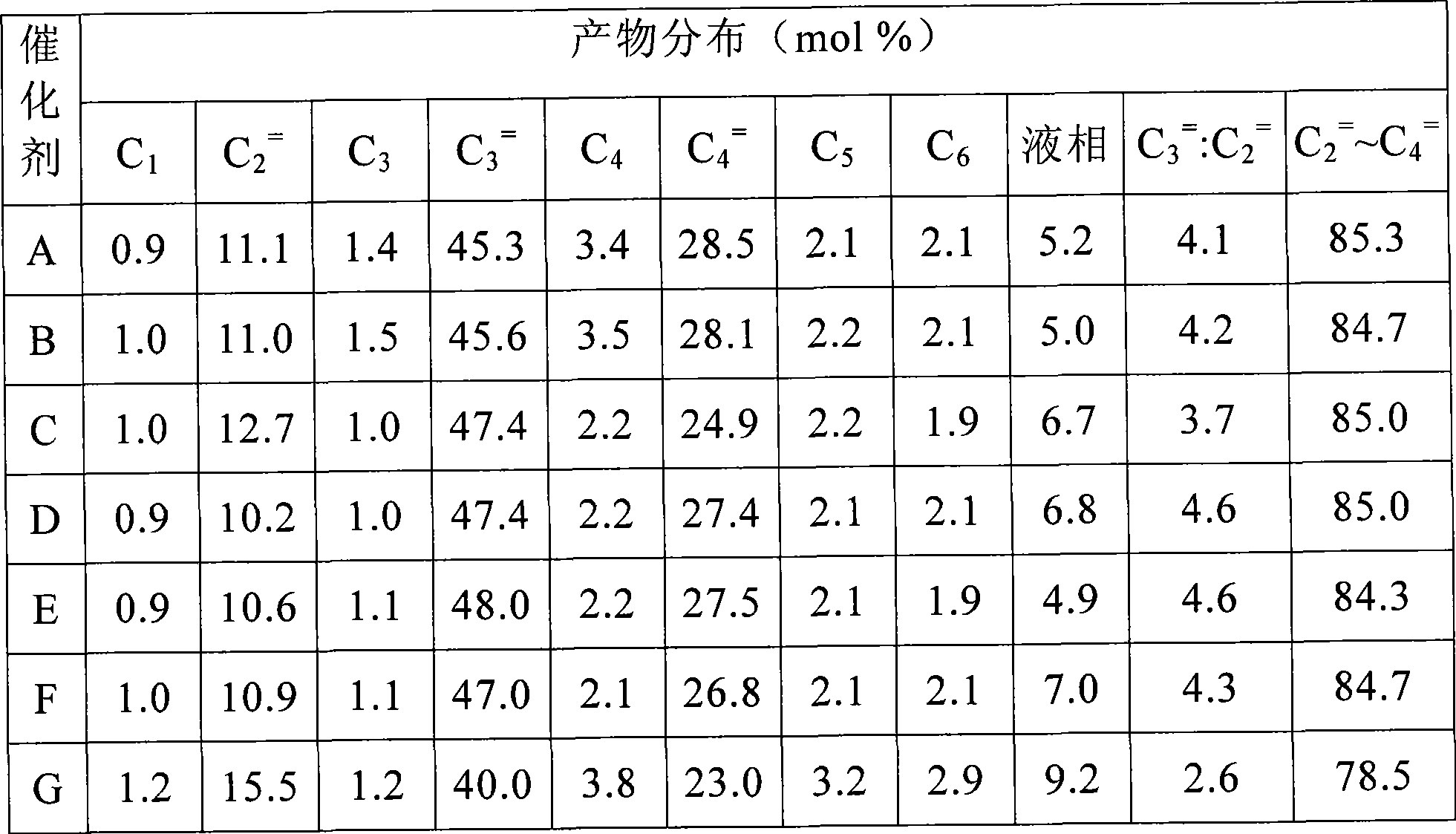

Examples

Embodiment 1

[0077] Take by weighing 100 grams of commercially available ZSM-5 molecular sieves (SiO 2 :Al 2 o 3 =80), added to 2000 grams of RECl 3 In the aqueous solution, RE represents the rare earths Ce and La, and the RECl in the aqueous solution 3 The mass content is 2%, CeCl 3 : LaCl 3 =2:1. Then stir, perform ion exchange at 95°C for 50 minutes, filter, and roast at 550°C for 2 hours, repeat the above steps once to obtain RE 2 o 3 RE-ZSM-5 seed crystals with a mass percent content of 21%.

[0078] Weigh 30 grams of the above-mentioned RE-ZSM-5 seed crystals and add them to 1800 grams of water glass solution; Na in the water glass solution 2 O mass content 3.6%, SiO 2 The mass content is 12%. Stir well, add 300 grams of 1.0% Al 2 o 3 Aluminum phosphate colloidal solution, adjust the pH value to 10.5 with a concentration of 8% phosphoric acid solution. The system was crystallized at 180°C for 20 hours, cooled, filtered, washed with water until neutral, and dried at 120°C...

Embodiment 2

[0088] Get the 2.2%RE that 100 grams of embodiment 1 prepares 2 o 3 RE-ZSM-5 molecular sieve, by molar ratio, SiO 2 :Al 2 o 3 =100,

[0089] Add 15 grams of alumina dry glue, mix well, and extrude into strips with a diameter of 3 mm. Dry at 120°C for 3 hours, and bake at 450°C for 4 hours. Prepare RE-HZSM-5 molecular sieve catalyst semi-finished product.

Embodiment 3

[0091] Take 10 grams of the RE-HZSM-5 molecular sieve catalyst semi-finished product prepared in Example 2, use 7 grams of magnesium acetate solution with a mass percentage of 10%, soak it at 60°C for 3 hours, dry it at 120°C for 3 hours, and use 100ml of water in the Steam treatment at 500°C for 3 hours, followed by calcination in air at 550°C for 6 hours, to prepare finished catalyst A. After analysis, the mass percentage of MgO in the catalyst was 1.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com