Advanced purification treatment system for high concentrated organic wastewater

A technology for deep purification of organic wastewater, applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of low purification degree of effluent, unsuitable for recycling, and low pollutant content To achieve the effect of improving the flocculation effect and sedimentation effect, improving the treatment effect and reducing the pollution level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

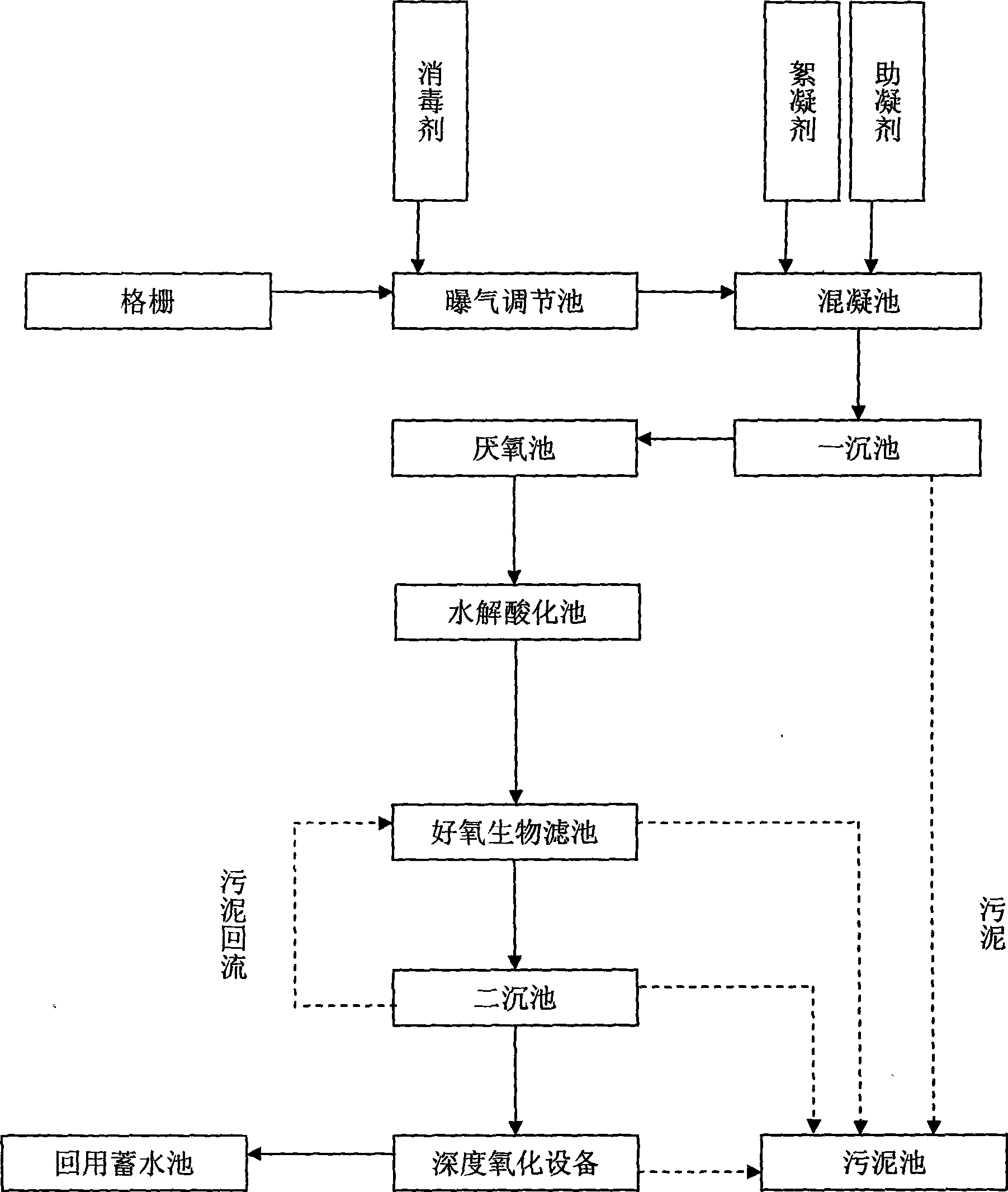

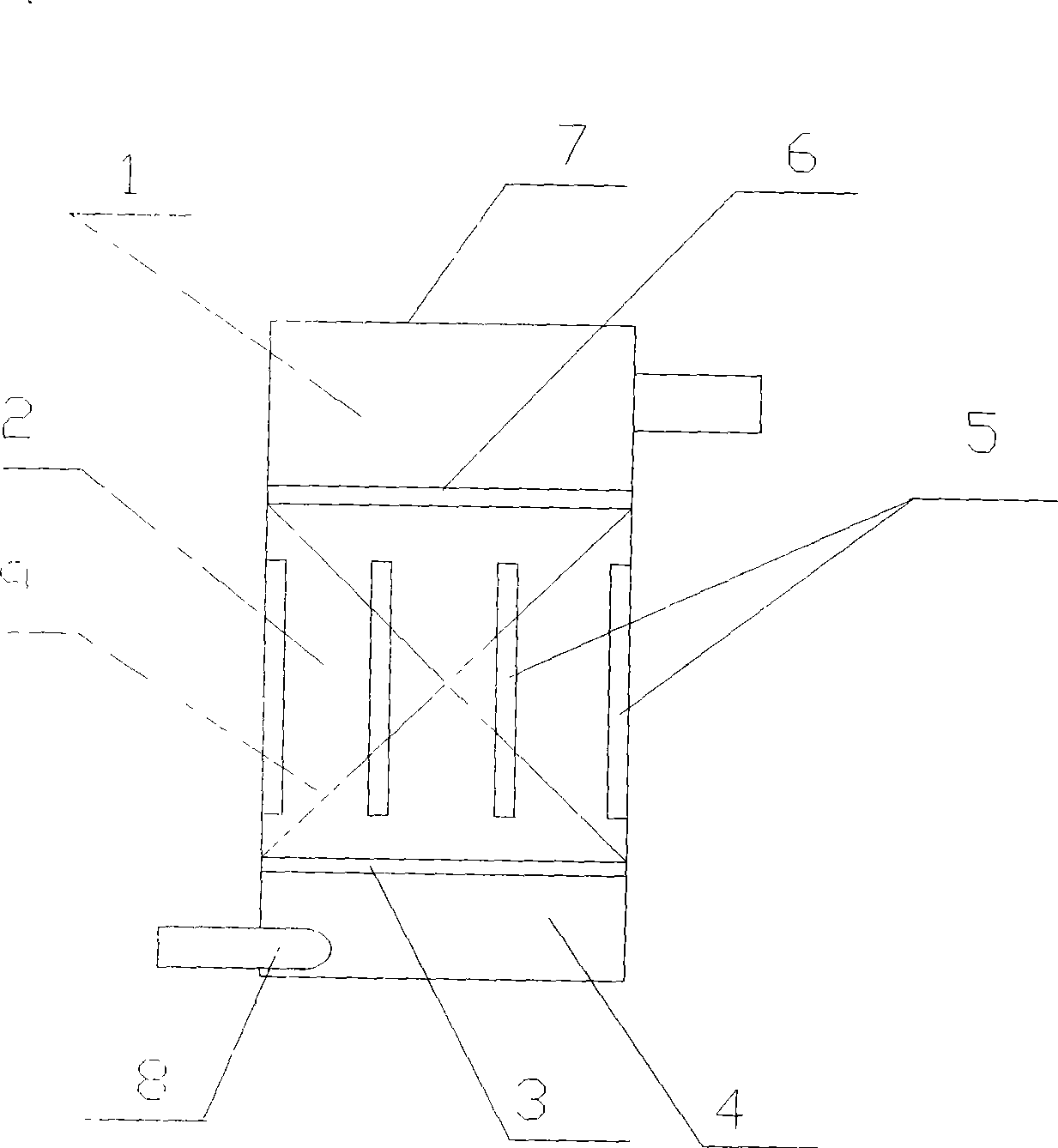

[0019] see figure 1 , the treatment facilities of the present invention are grille, aeration regulating tank, coagulation tank, primary sedimentation tank, anaerobic tank, hydrolytic acidification tank, aerobic biological filter, secondary sedimentation tank, deep oxidation equipment and reuse water storage The pool is composed of pipes or corresponding overflow weirs to realize the water flow connection between each other. After the raw wastewater passes through the grille, the large materials such as waste gauze contained in it are intercepted. The grille can be in any form, usually can be divided into There are two levels of thickness and thickness, the coarse grid adopts a bar shape, and the fine grid adopts a grid shape. The aeration regulating tank is equipped with aeration equipment, which automatically adjusts the aeration volume according to the water inflow. The water inflow can be obtained from the data of the inflow flow meter arranged behind the grille, or the aer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com