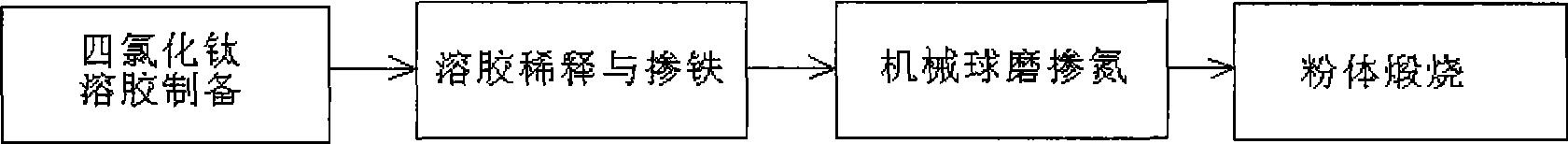

Preparation of iron-doped nitrogen-doped nano titanium dioxide powder

A nano-titanium dioxide, titanium dioxide technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide and other directions, can solve the problems of affecting the absorption of titanium dioxide powder, affecting the nano-effect of powder, particle growth, etc. Catalytic performance, expanding the wavelength of light response, and improving the effect of photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

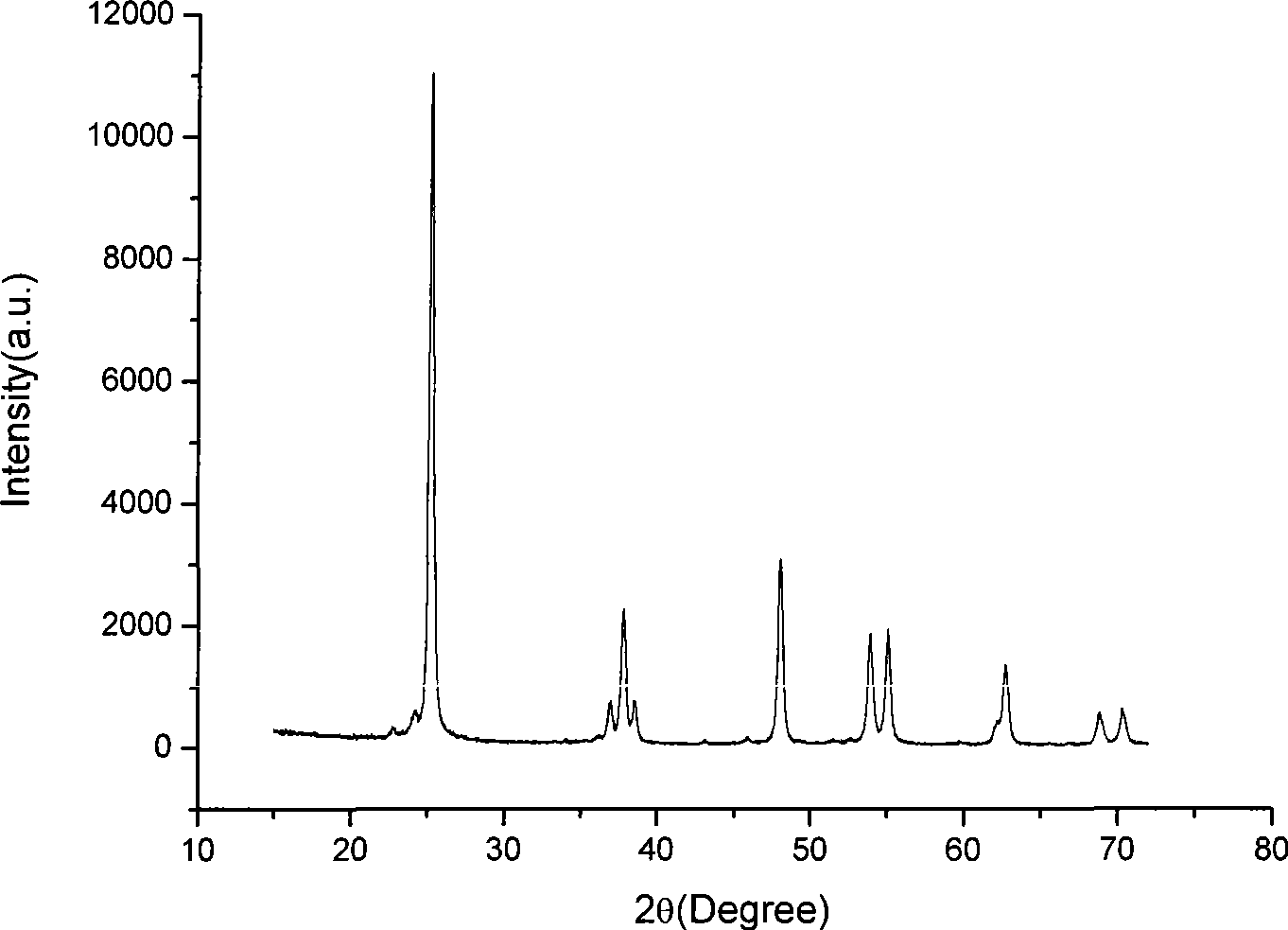

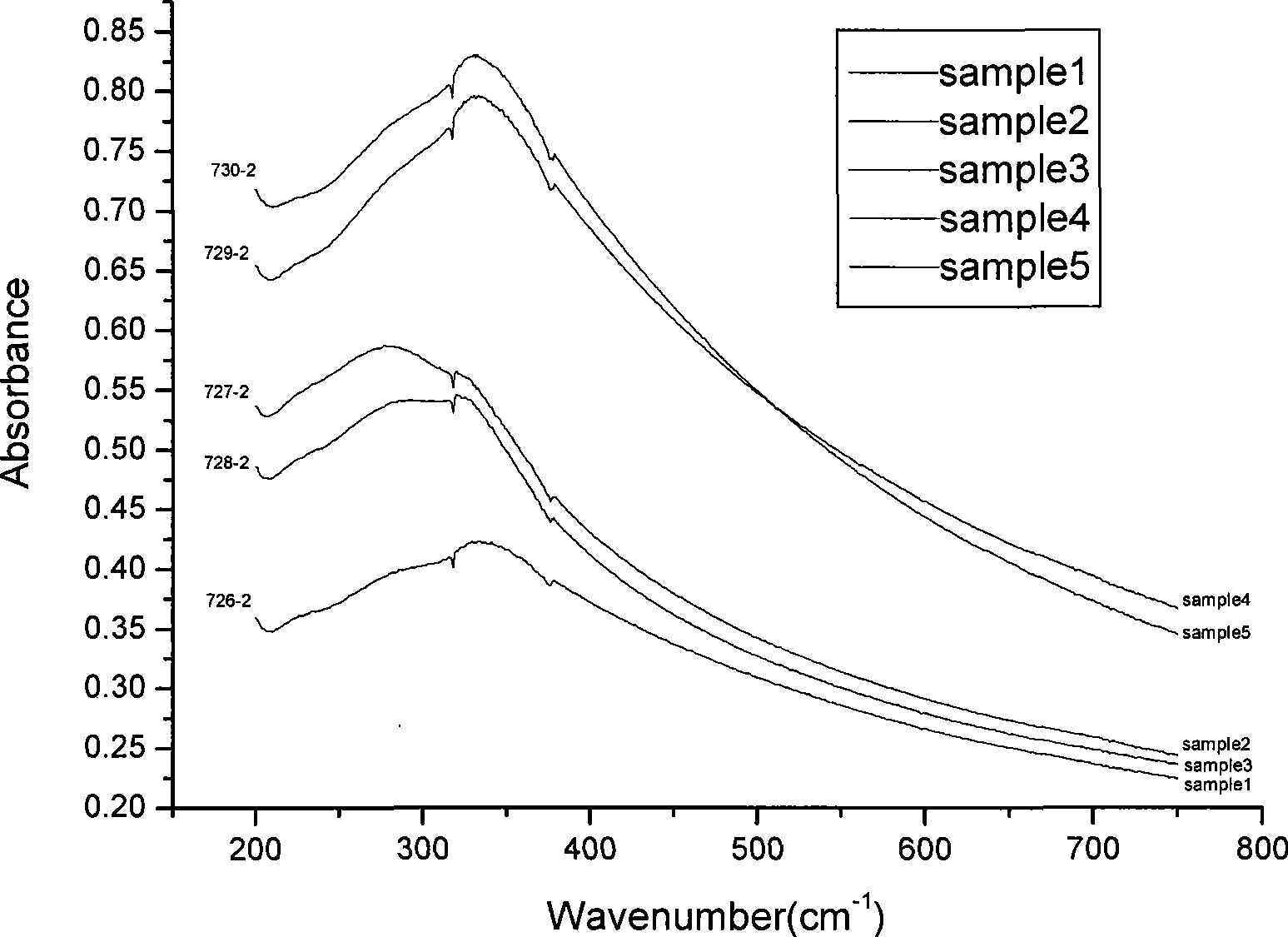

Embodiment 1

[0032] (1) Fix a three-necked bottle with a capacity of 1000mL in an ice-water bath, take 300mL of pure water (H20) and put it into the three-necked bottle; install a condenser tube on the middle port of the three-necked bottle, and use tap water to condense; install Contact thermometer to monitor and control the temperature of the reaction system; take TiCl 4 Put 300mL into a dry constant-pressure separating funnel, and install the constant-pressure separating funnel on the other side port of the three-necked flask; under the conditions of magnetic stirring and ice-water bath cooling, turn on the switch of the constant-pressure separating funnel, The titanium chloride solution is slowly dropped into pure water, and the temperature of the entire dropping and mixing process is controlled at about 40°C by controlling the dropping speed and the temperature of the ice-water bath; with the addition of titanium tetrachloride, the color of the system gradually changes, From colorless...

Embodiment 2

[0038] (1) Fix a three-necked bottle with a capacity of 1000mL in an ice-water bath, take pure water (H 2 (2) 400mL is packed in the there-necked bottle; A condenser is installed on the middle port of the there-necked bottle, and utilizes tap water to condense; A contact type thermometer is installed on a mouth of the there-necked bottle, to monitor and control the temperature of the reaction system; Take TiCl 4 150mL was put into a dry constant pressure separating funnel, and the constant pressure separating funnel was installed on the other side port of the three-necked flask; under the conditions of magnetic stirring and ice-water bath cooling, the switch of the constant pressure separating funnel was turned on, The titanium chloride solution is slowly dropped into pure water, and the temperature of the entire dropping and mixing process is controlled at about 10°C by controlling the dropping speed and the temperature of the ice-water bath; with the addition of titanium tet...

Embodiment 3

[0045] (1) Fix a three-neck bottle with a capacity of 100mL in an ice-water bath, take pure water (H 2 (2) 400mL is packed in the there-necked bottle; A condenser is installed on the middle port of the there-necked bottle, and utilizes tap water to condense; A contact type thermometer is installed on a mouth of the there-necked bottle, to monitor and control the temperature of the reaction system; Take TiCl 4 Put 100mL into a dry constant-pressure separating funnel, and install the constant-pressure separating funnel on the other side port of the three-necked flask; under the condition of magnetic stirring and ice-water bath cooling, turn on the switch of the constant-pressure separating funnel, The titanium chloride solution is slowly dropped into the pure water, and the temperature of the whole dropping and mixing process is controlled at about 0°C by controlling the dropping speed and the temperature of the ice-water bath; with the addition of titanium tetrachloride, the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com