Method for synthesizing hexagonal phase TbPO4 H2O nano/micron multi-stage structural material

A synthesis method and technology of structural materials, applied in the field of rare earth phosphates, can solve the problems of unfavorable large-scale production and application, non-recyclable raw materials, high synthesis temperature, etc., and achieve the effects of low raw material prices, easy industrial production, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

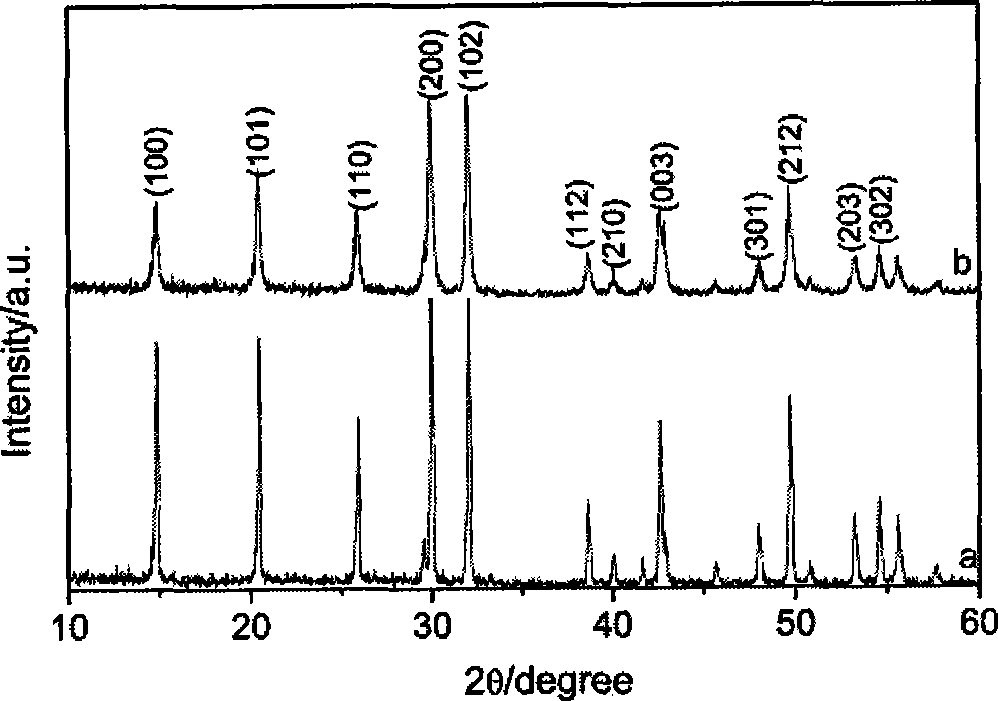

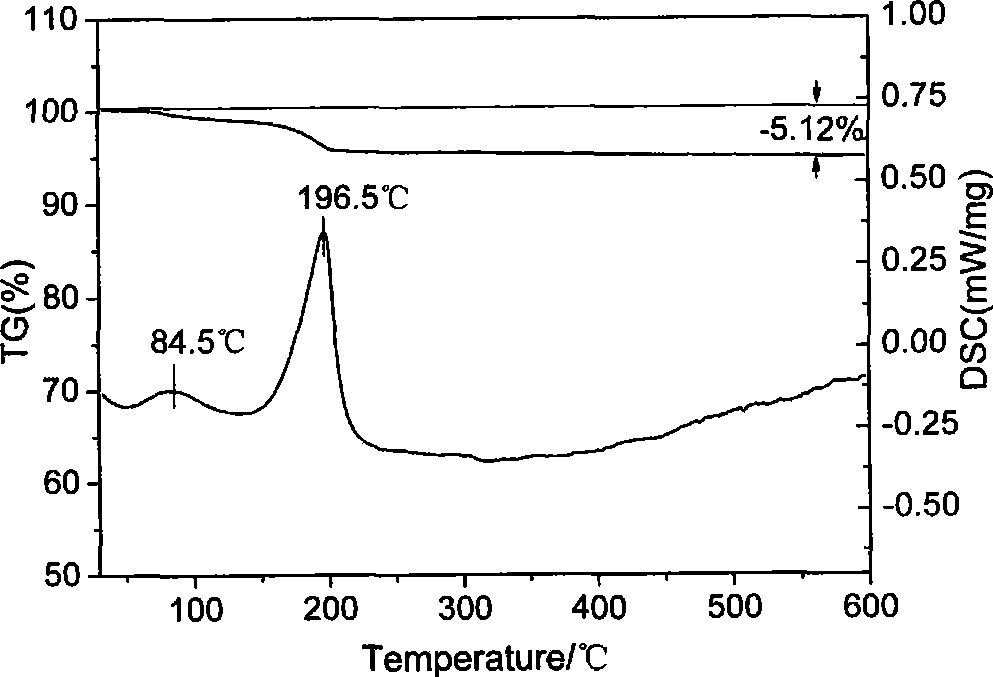

[0021] Take 0.453g Tb(NO 3 ) 3 ·6H 2 O was dissolved in 10mL of distilled water and added dropwise to 10mL of 6mol / L H 3 PO 4 , making it PO 4 The / Tb molar ratio is 60, stirred for 20mim, and transferred to the reaction kettle. React at 100°C for 6 hours, wash with distilled water and absolute ethanol three times, and dry at 60°C to obtain a white powder. XRD pattern shows that the product is hexagonal phase TbPO 4 ·nH 2 O (such as figure 1 a curve in); According to the TG-DSC (thermogravimetric-scanning differential calorimetry) curve, it is calculated that 196.5 ° C loses 1mol of crystal water, and the TG-DSC curve shows that the resulting product is TbPO 4 ·H 2 O (such as figure 2 ); SEM photos show that the resulting product is a hexagonal prism with a diameter of about 700 to 800 nm and a length of several microns with better monodispersity (such as Figure 5 ).

Embodiment 2

[0023] Take 0.680g Tb(NO 3 ) 3 ·6H 2 O was dissolved in 10mL of distilled water and added dropwise to 10mL of 6mol / L H 3 PO 4 , making it PO 4 The / Tb molar ratio is 40, stirred for 20mim, and transferred to the reaction kettle. React at 100°C for 8 hours, wash with distilled water and absolute ethanol three times, and dry at 60°C to obtain a white powder. SEM photos show that the obtained product is a hexagonal prism with a diameter of about 400 to 500 nm and a length of several microns with good monodispersity (such as Image 6 ).

[0024] Spindle-shaped TbPO composed of nanorods 4 ·H 2 Preparation of O nanostructures:

[0025] Embodiment one

[0026] Take 0.680g Tb(NO 3 ) 3 ·6H 2 O was dissolved in 10mL of distilled water and added dropwise to 10mL of 6mol / L H 3 PO 4 , making it PO 4 The / Tb molar ratio is 40, after stirring for 20mim, adjust the pH value of the system to 1.4 with concentrated ammonia water, and transfer it to the reaction kettle. React at 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com