Novel rivastigmine preparation

A compound and methylation technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of carbamate derivatives, etc., can solve the problems of no synthesis route and examples, low yield, large loss, etc., and achieve pollution. Small, high reaction yield, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

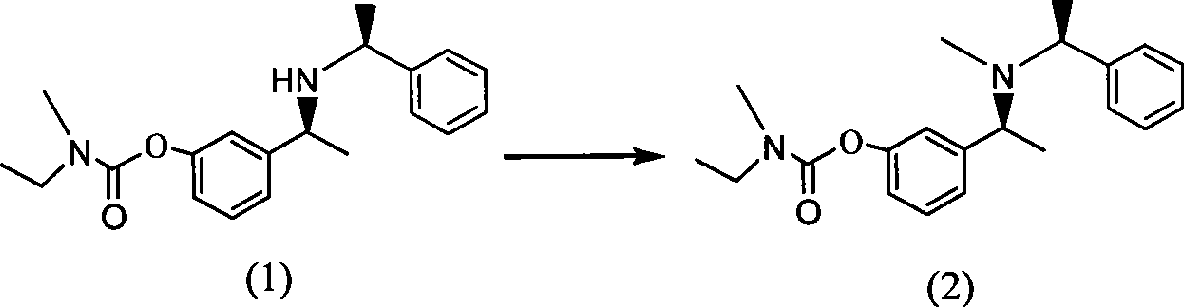

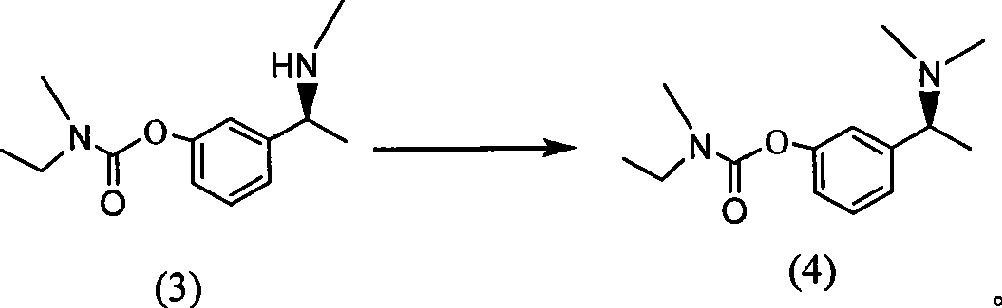

[0038] Example 1: Preparation of 3-((S)-1-((S)-1-phenethylamino) ethyl) phenylethyl (methyl) carbamate (compound 1)

[0039] 10g (0.05mol) of 3-acetylphenylethyl (methyl) carbamate (formula 5), 5.5g (0.05mol) of (S)-1-phenylethylamine, tetraisotitanate 19g (0.07mol) of propyl ester and 85ml of ethyl acetate were stirred and reacted at 30°C for 2 hours, 0.5g of 10% palladium carbon was added, hydrogen was passed, and the reaction was carried out at 65°C and 15atm for 15 hours, and the reaction of compound (5) was monitored by TLC. Cooling and suction filtration, add 100ml of 1N sodium hydroxide solution to the mother liquor, stir at room temperature for 1 hour, suction filtration, separate layers of the mother liquor, extract the water layer with 50ml of ethyl acetate twice, combine the ethyl acetate layers, and wash with saturated saline 80ml× Washed 3 times, dried with anhydrous sodium sulfate, then sucked and spin-dried to obtain 13.5 g of a yellow clear liquid with a yiel...

Embodiment 2

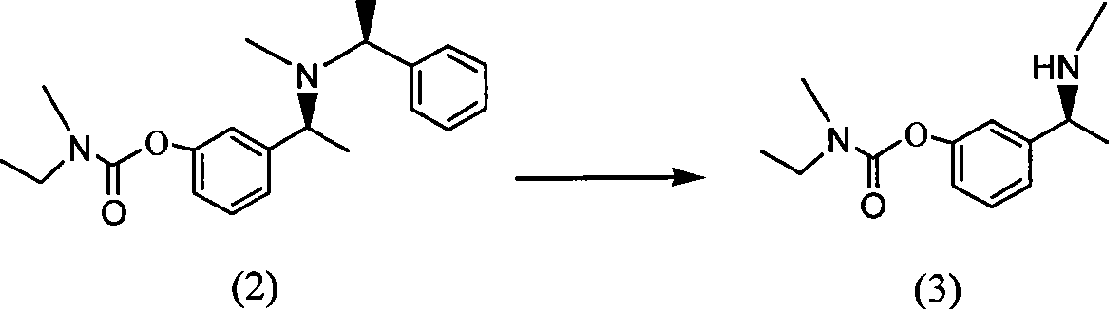

[0040] Example 2: 3-((S)-1-(methyl((S)-1-phenylethyl)amino)ethyl)phenylethyl(methyl)carbamate (compound 2) preparation

[0041] Put 10g (0.03mol) of compound (1) into the reactor, 1.8g (0.06mol) of paraformaldehyde and 5ml (0.11mol) of 88% formic acid, heat and stir at 95°C for 8 hours, cool, and spin dry at 60°C , add 30ml of 10% sodium hydroxide solution and 30ml of ethyl acetate, stir at room temperature for 0.5 hours, separate the layers, extract the water layer with 30ml of ethyl acetate x 2 times, separate the layers, combine the ethyl acetate layers, and wash with saturated saline 50ml ×Washed twice, dried with anhydrous sodium sulfate, then suction filtered and spin-dried to obtain 9.5 g of light yellow clear liquid with a yield of 91%.

Embodiment 3

[0042] Example 3: 3-((S)-1-(methyl((S)-1-phenylethyl)amino)ethyl)phenylethyl(methyl)carbamate (Compound 2) preparation

[0043] Put into the reactor 10g (0.03mol) of compound (1), 1.8g (0.06mol) of paraformaldehyde and 5ml (0.11mol) of 88% formic acid, heat and stir at 45°C for 42 hours, spin dry at 60°C, add 30ml of 10% sodium hydroxide solution and 30ml of ethyl acetate, stirred at room temperature for 0.5 hours, separated into layers, extracted the water layer with 30ml of ethyl acetate x 2 times, separated into layers, combined the ethyl acetate layers, and washed with saturated saline 50ml x 2 Washed for three times, dried with anhydrous sodium sulfate, and then sucked and spin-dried to obtain 8.6 g of light yellow clear liquid with a yield of 82%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com