Preparation of composite bacteria

A production method and technology of composite bacteria, applied in the direction of using microorganisms, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of inability to grasp the composition of bacteria, low decomposition efficiency, unstable effect, etc., to achieve The effect of good stability and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

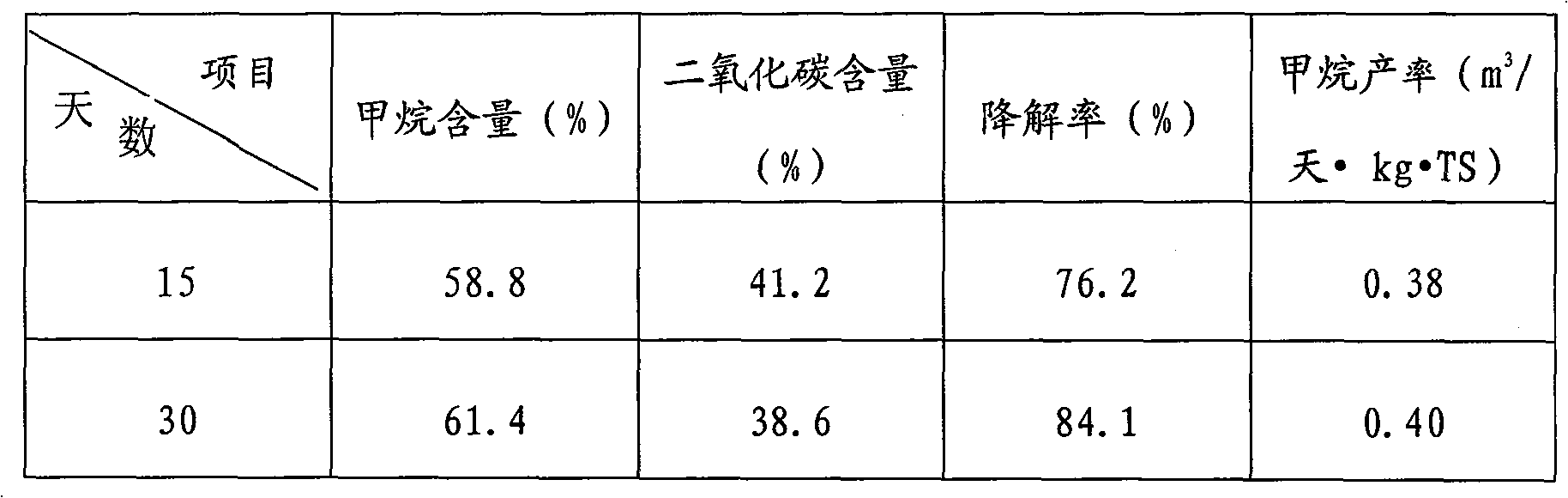

Embodiment 1

[0029] The following 13 strains were mixed and inoculated in a cellulose-containing culture solution, sealed and allowed to stand and cultivated at a culture temperature of 40°C and a pH of 6.5. The ratio of the number of cells of each strain to the total number of complex bacteria in the 13 strains was respectively They are: Cytophaga fermentans 10%, Clostridium papyrosolvens 25%, Desulfovibrio vulgaris 1%, Butyrivibrio fibrisolvens 5%, Acetobacterium woodii 5%, Cellulomonas flavigena 1%, Clostridium termitidis 1%, Clostridium cellobioparum 2.5% Wolfei 5%, Methanosarcina barkeri 19%, Methanobrevibacter arboriphilicus 15%, Methanosphaera stadtmaniae 8%, and Methanococcus vannielii 2.5%. The formula of the above-mentioned cellulose-containing culture solution is as follows: NaCl 3‰, cellulose (straw) 5‰, urea 1‰, peptone 1‰, yeast powder 0.5‰, CaCO 3 2‰, with water as solvent, the above content refers to CaCO 3 The ratio of the quality of NaCl, cellulose, urea, peptone, and yeas...

Embodiment 2

[0033] The following 13 strains were mixed and inoculated in a cellulose-containing culture solution, sealed and allowed to stand and cultivated at a culture temperature of 40°C and a pH of 6.5. The ratio of the number of cells of each strain to the total number of complex bacteria in the 13 strains was respectively Cytophaga fermentans accounted for 7.5%, Clostridium papyrosolvens accounted for 35%, Desulfovibrio vulgaris accounted for 3%, Butyrivibrio fibrisolvens 4%, Acetobacterium woodii accounted for 5%, Cellulomonas flavigena accounted for 5%, Clostridium termitidis accounted for 3%, and Clostridium cellobioparum accounted for 5%. Wolfei 5%, Methanosarcina barkeri 10%, Methanobrevibacter arboriphilicus 10%, Methanosphaera stadtmaniae 5%, and Methanococcus vannielii 2.5%. The formula of the above-mentioned cellulose-containing culture solution is as follows: NaCl 5‰, cellulose (straw) 8‰, urea 2‰, peptone 2‰, yeast powder 1‰, CaCO 3 2‰, with water as solvent, the above con...

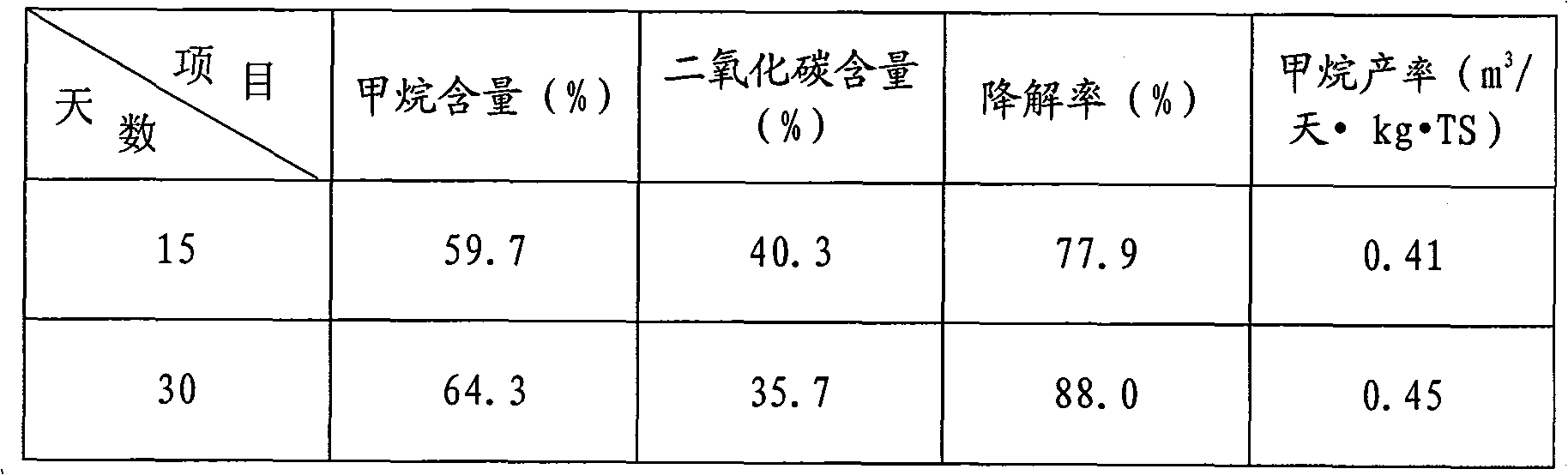

Embodiment 3

[0038] The following 13 strains were mixed and inoculated in a cellulose-containing culture solution, sealed and allowed to stand and cultivated at a culture temperature of 40°C and a pH of 6.5. The ratio of the number of cells of each strain to the total number of complex bacteria in the 13 strains was respectively As follows: Cytophaga fermen tans accounted for 5%, Clostridium papyrosolvens accounted for 30%, Desulfovibrio vulgaris accounted for 1%, Butyrivibrio fibrisolvens 5%, Acetobacterium woodii accounted for 5%, Cellulomonas flavigena accounted for 5%, Clostridium termitidis accounted for 2%, Clostridium celloparitidis accounted for 2%, Syntrophomonas Wolfei 6%, Methanosarcina barkeri 20%, Methanobrevibacter arboriphilicus 10%, Methanosphaera stadtmaniae 5%, and Methanococcus vannielii 3%. The formula of the above-mentioned cellulose-containing culture solution is as follows: NaCl 7‰, cellulose (straw) 10‰, urea 4‰, peptone 3‰, yeast powder 1.5‰, CaCO 3 2‰, with water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com