Micro-machine overhang beam simultaneously implementing driving and self-cleaning with single integrated resister

A technology integrating resistors and cantilevers, applied in the field of micromechanical sensors, can solve the problems of unfavorable portable sensors, bulky equipment, and increase the complexity of devices, and achieve the effect of optimizing the selection of driving current, simplifying the structure, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Streptavidin biosensor

[0036] An implementation example of detecting streptavidin is used to illustrate the performance of the sensor of the present invention in detail.

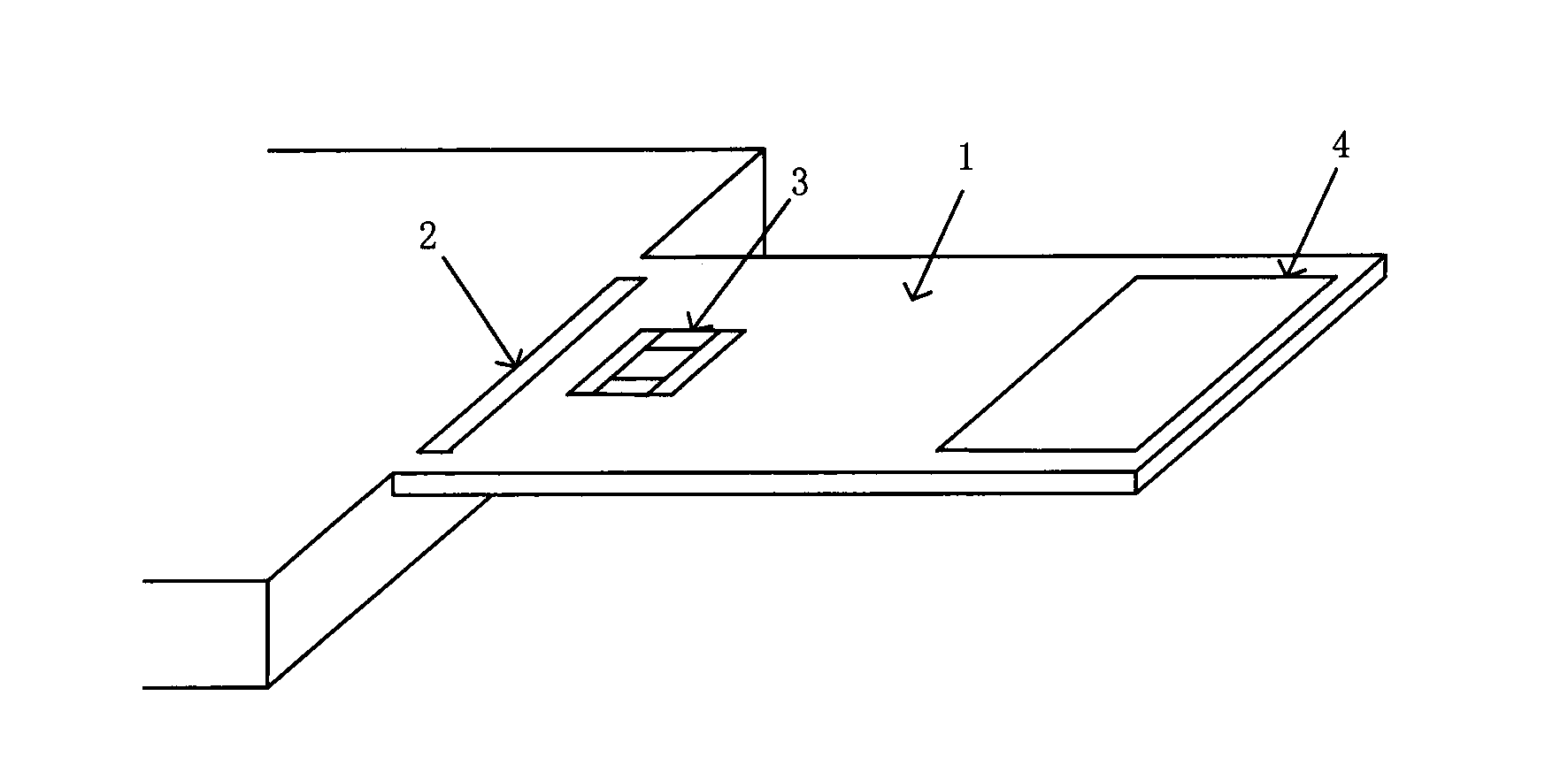

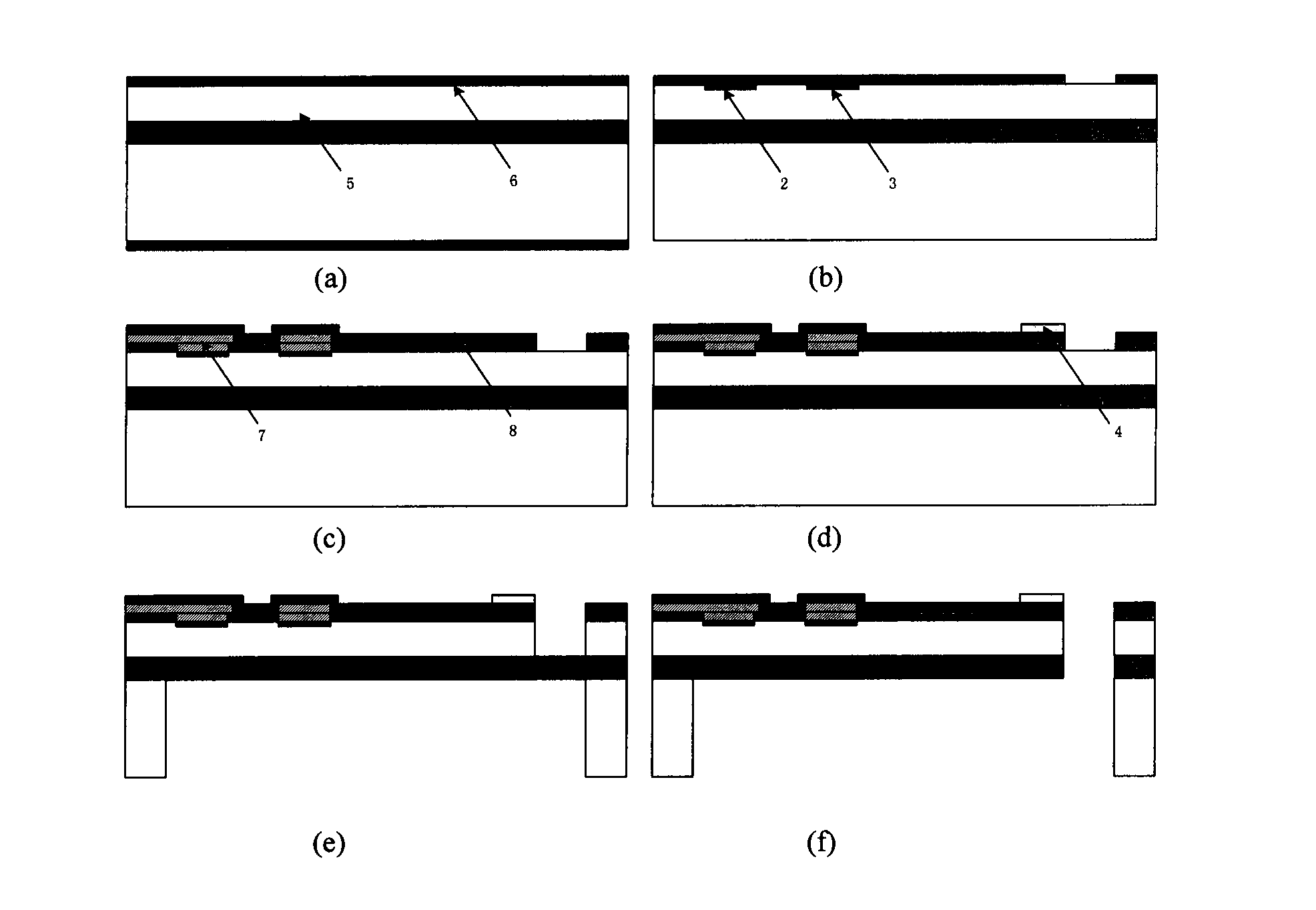

[0037] The scanning electron microscope photograph of the cantilever beam is shown as Figure 4 shown. Its size is 300 μm × 100 μm × 3 μm, the size of the driving resistor is 2.12 kΩ, and the size of the gold film is 94 μm × 45 μm × 0.05 μm. The working principle of the sensor is as follows: Molecules self-assemble on the surface of the gold film to form a layer of GOPS (glycidoxytrimethoxysilane) film, and then cover the rest of the cantilever beam with a layer of PEG (polyethylene glycol) molecules to Inhibition of non-specific adsorption, followed by self-assembled growth of biotin on GOPS film as a sensitive membrane for specific adsorption of streptavidin. When the sensor is immersed in a solution containing streptavidin, streptavidin will be specifically adsorbed to the surface o...

Embodiment 2

[0046] Example 2: DMMP chemical sensor

[0047] This embodiment takes the detection of saturated DMMP (dimethyl phosphonate) gas as an example to describe in detail the application of the present invention in chemical gas detection and its self-cleaning function.

[0048] DMMP is a simulant of sarin gas. Sarin is a dangerous substance with great harm. It has been used in terrorist attacks and caused serious consequences. Effective detection of sarin gas will provide technical support for security checks and anti-terrorism at transportation hubs and important locations such as airports, stations, ports, and customs, and is of great significance to ensuring public safety.

[0049] Each design of the sensor is the same as that of Embodiment 1, except that the sensitive film deposited on the gold film is different. The sensor first grows a layer of hyperbranched polymer on the gold film, and then grows a DMMP-sensitive head group on it. The fabrication process of the device is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com