Polishing composition

A composition and compound technology, applied in polishing compositions containing abrasives, grinding machine tools, grinding devices, etc., to achieve the effects of high flatness and sufficient grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

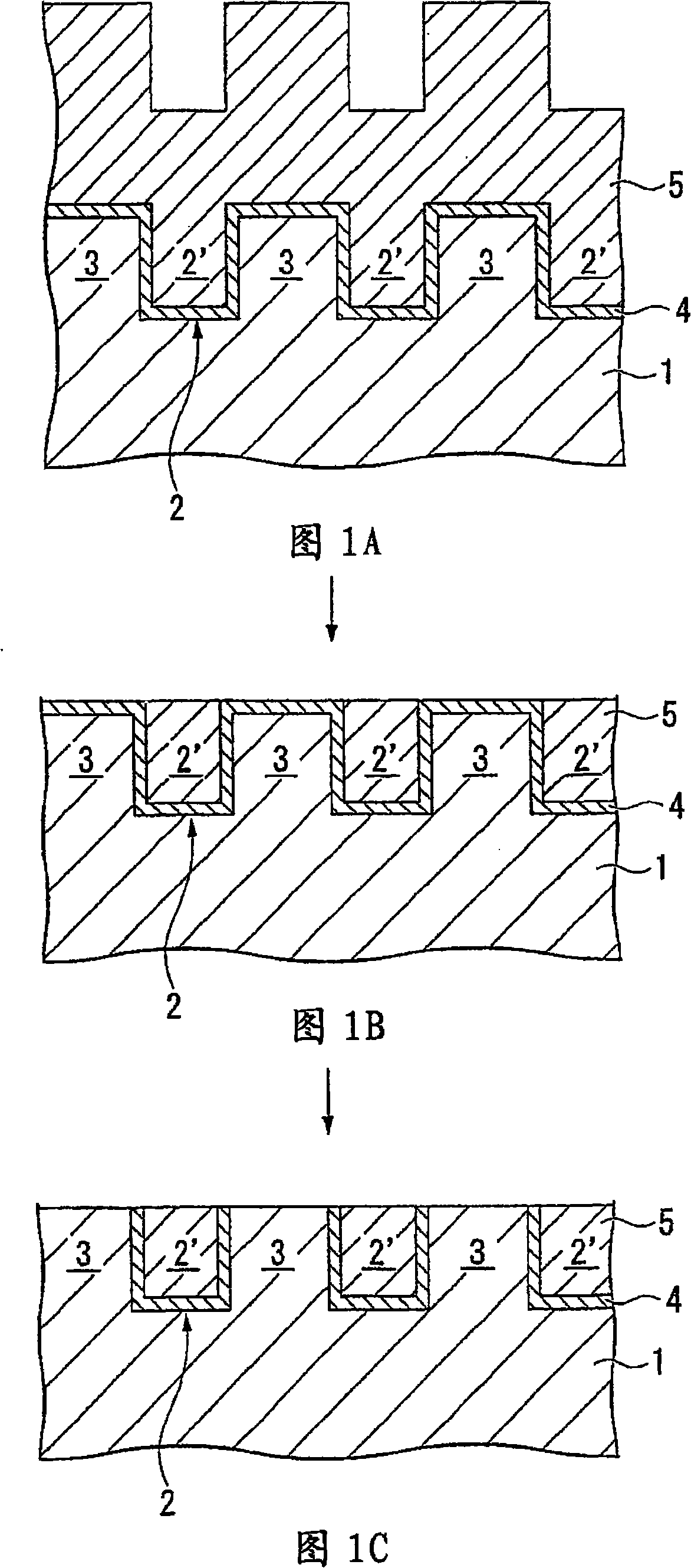

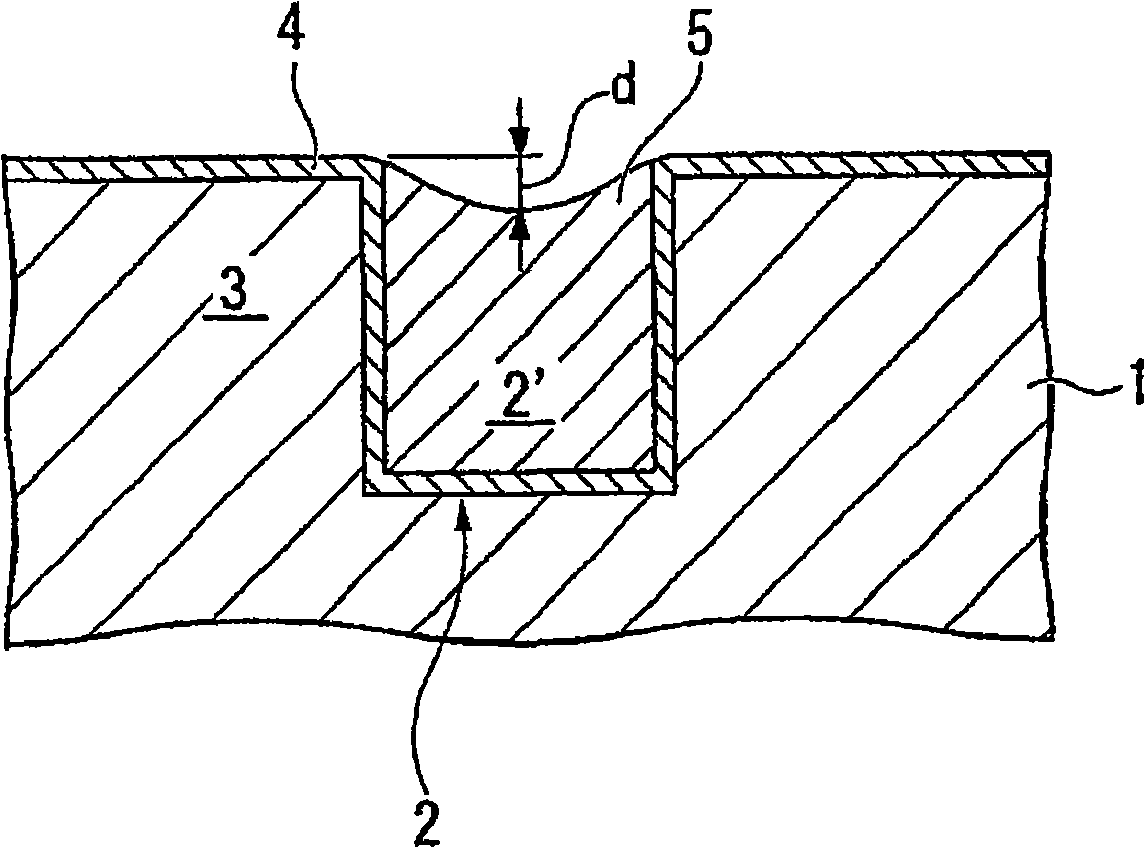

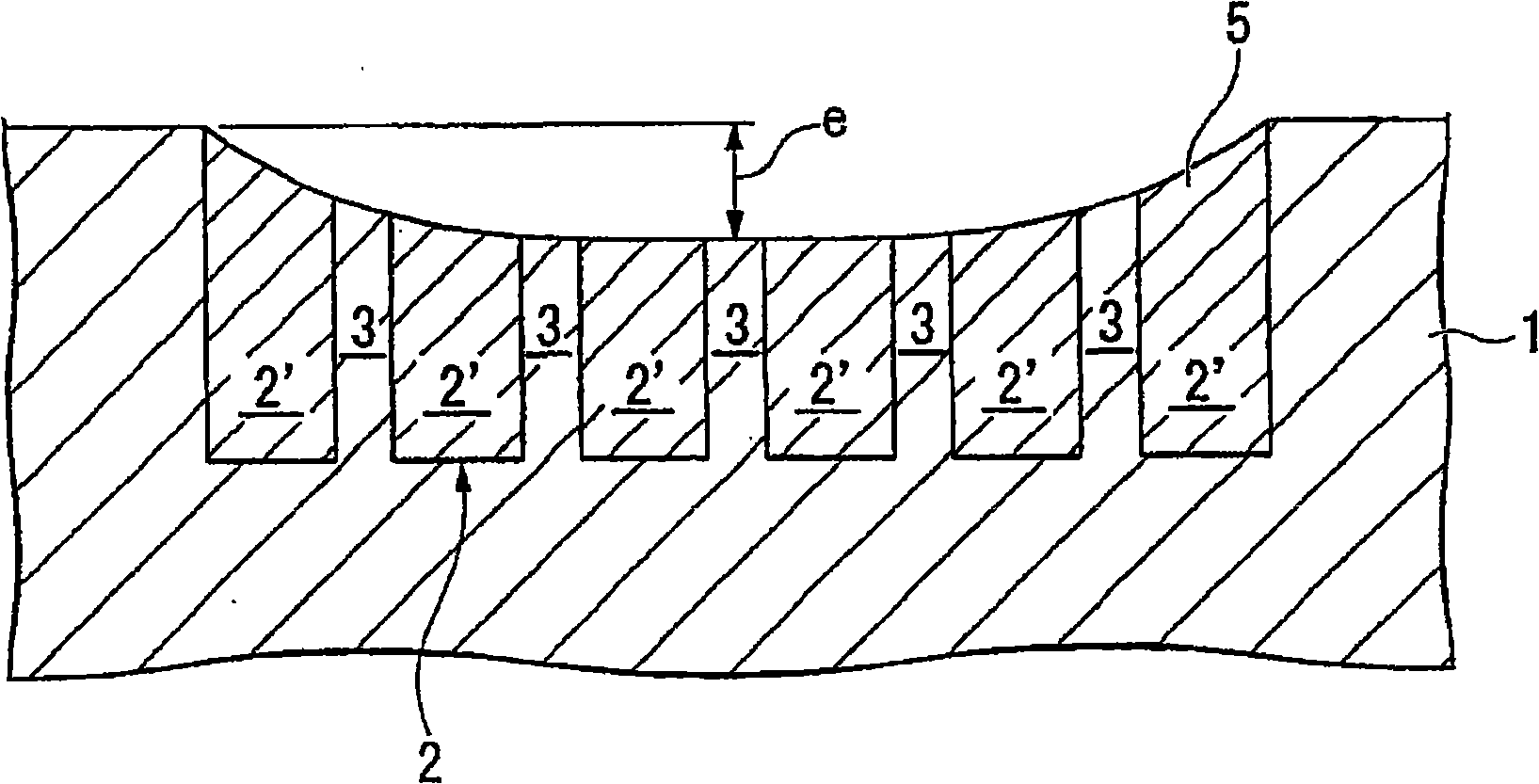

Method used

Image

Examples

Embodiment

[0188] Hereinafter, although an Example is given and this invention is demonstrated in detail, this invention is not limited by these Examples.

Synthetic example

[0189] (Synthesis example: azole group-containing compound)

[0190] Hereinafter, although the synthesis examples of the azole group-containing compound containing 3 or more azole groups are shown, this invention is not limited to these synthesis examples.

[0191]

[0192] In the 500ml flask equipped with thermometer, stirring device, nitrogen inlet tube and reflux condenser, add 30g of n-propanol, under nitrogen atmosphere, while stirring, be warming up to reflux temperature (about 98 ℃). A liquid obtained by dissolving 15.72 g of 1-vinylimidazole, 74.28 g of 1-vinylpyrrolidone, and 0.066 g of 2-mercaptoethanol in 29.93 g of n-propanol (hereinafter referred to as mono-propanol) was added thereto by a quantitative pump. body solution.), and 0.77g dimethyl-2,2'-azobis (2-methylpropionate) dissolved in 215.23g of n-propanol liquid (hereinafter referred to as initiator solution 1 ). Addition time: 4 hours for both solutions. After adding these monomer solutions and ...

Embodiment 1~3、 comparative example 1

[0214] In Examples 1 to 3 and Comparative Example 1, SH-24 manufactured by Speed Farm was used as a grinder, and an 8-inch wafer (200 mm wafer) was evaluated. Polishing was performed at a relative speed of the substrate and the polishing table at 70 m / min, a polishing composition supply rate of 150 ml / min, and a pressure of 15 kPa.

[0215] As a polishing pad, IC1400 (k groove) manufactured by Rodelnita Co., Ltd. was used. The compositions of these Examples 1 to 3 and Comparative Example 1 are shown in Table 1.

[0216] In addition, in Table 1, the addition amount of each composition is shown by mass %. In addition, the additive other than Table 1 is water. Among them, APS means ammonium persulfate, DBS means dodecylbenzenesulfonic acid, and POE means polyoxyethylene 2-level alkyl ether phosphate (addition of secondary alcohol with an average carbon number of 13 and an average of 3 mol of ethylene oxide) (formed by phosphating the obtained alcohol with the raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com