Production of rosin based aqueous polyurethanes

A water-based polyurethane and rosin-based technology, applied in the field of preparation of rosin-based water-based polyurethane, can solve the problems of low hardness, poor water resistance, low gloss of water-based polyurethane, etc., and achieve the effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A preparation method of rosin-based water-based polyurethane, the steps are:

[0020] The first step is to prepare rosin-based polyester polyol: compound the modified rosin polyacid alone or with a dibasic acid with 3 to 6 carbon atoms in any ratio, and then mix it with a small molecule polyol, and the alkyd ratio is 1:1.1 -1:1.6, a rosin-based polyester polyol with a number average molecular weight of 500-3000 prepared through dehydration condensation reaction at 150-270°C;

[0021] The second step is to prepare rosin-based water-based polyurethane: the rosin-based polyester polyol obtained in the first step is compounded alone or with polyether polyol or polyester polyol in any ratio, and vacuum dehydrated at 100-120°C for 2-3 After cooling, add diisocyanate and catalyst to react at 60-90°C for 1-3 hours, then add hydrophilic monomer and react at 60-90°C for 1-2 hours, then add organic solvent and small molecule chain extender at 0-90°C React at 70°C for 3 to 6 hours...

Embodiment 1

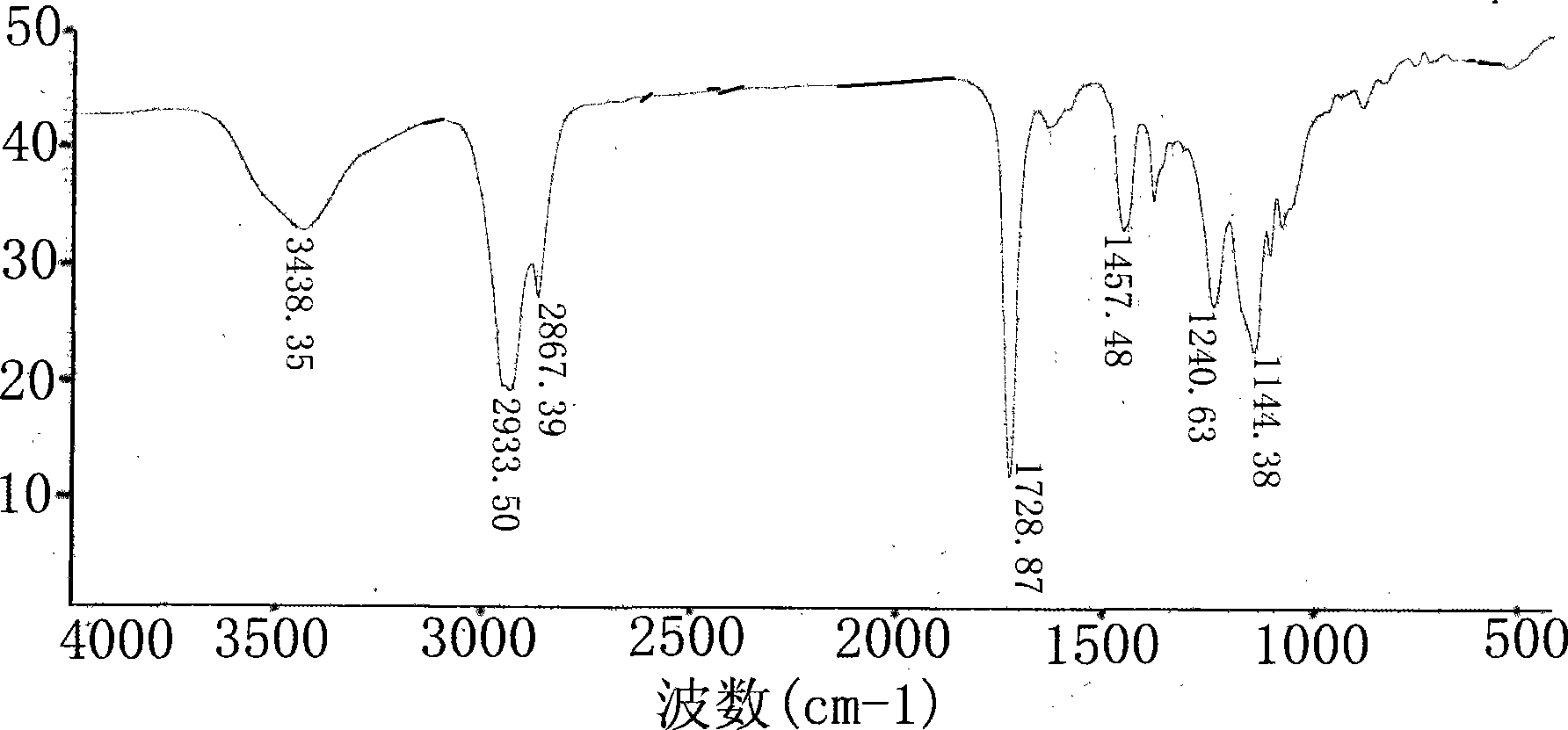

[0030] Add propylene pimaric acid 74.8g, 1,4-butanediol 27g in the 500ml flask that is equipped with thermometer, agitator, air guide tube, distillation head, 220 ℃ react until the acid value of the system drops to 40mg / g, then vacuum condition The reaction was carried out until the acid value of the system dropped below 3 mg / g, and the temperature was lowered to 160° C. to discharge to obtain a rosin-based polyester polyol with a hydroxyl value of 95.44 mg / g. Depend on figure 1 It can be seen that at 3438.35cm -1 Contains the characteristic absorption peak of hydroxyl at 1728.87cm -1 contains the characteristic absorption peak of ester carbonyl, indicating that the product is indeed a polyester polyol.

[0031] Take 10g of the above-mentioned rosin-based polyester polyol and 15g of polyether N-210, vacuum dehydrate at 120°C for 2-3 hours, add 16g of toluene diisocyanate and 0.02g of dibutyltin dilaurate after cooling, and react at 85°C for 1.5 hours , then add 2.3g of dimeth...

Embodiment 2

[0036] Add propylene pimaric acid 74.8g, diethylene glycol 42.4g in the 500ml flask that is equipped with thermometer, agitator, air guide tube, distillation head, 220 ℃ react until the acid value of the system drops to 40mg / g, then vacuum condition The reaction was carried out until the acid value of the system dropped below 3 mg / g, and the temperature was lowered to 160° C. to discharge to obtain a rosin-based polyester polyol with a hydroxyl value of 195.37 mg / g.

[0037] Take the above-mentioned rosin-based polyester polyol 5g, polyether N-210 15g, vacuum dehydrate at 100-120°C for 2-3 hours, add 16g of toluene diisocyanate and 0.02g of dibutyltin dilaurate after cooling, and react at 85°C After 1.5 hours, add 2.3g of dimethylolpropionic acid, react at 85°C for 1 hour, finally add 4.3g of diethylene glycol and 12g of acetone, react at 60°C for 4-5 hours, add triethylamine to neutralize after cooling, Stir vigorously, disperse in 100 g of water at a rotational speed of 600 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com