Modified nano molecular sieve catalyst for cracking endothermic hydrocarbon fuels and preparation method

A technology of nano-molecular sieves and hydrocarbon fuels, which is applied in the direction of molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., and can solve problems such as unfavorable normal operation of aircraft, unfavorable heat diffusion, and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

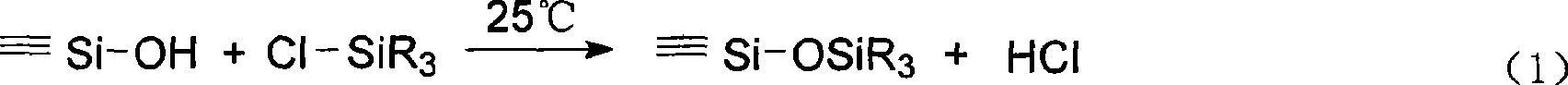

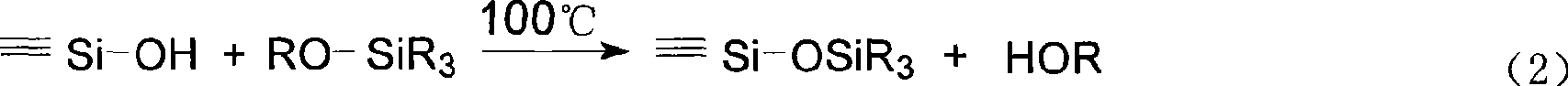

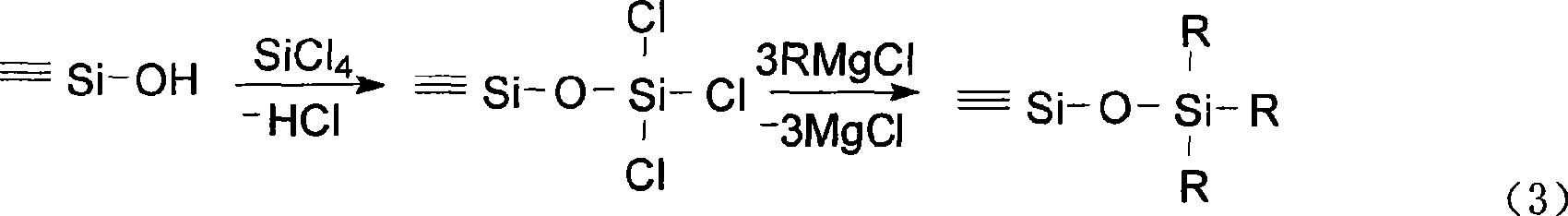

Method used

Image

Examples

Embodiment 1

[0031] Preparation of methyl functionalized nanometer HZSM-5 molecular sieve catalyst:

[0032] (1) Weigh 80g of Na-type nano ZSM-5 molecular sieve and place it in a 1L round bottom flask, add 800ml of ammonium nitrate solution with a concentration of 0.4mol / L, and stir in a constant temperature water bath at 80°C for 2h. After the reaction, filter, wash with deionized water repeatedly until neutral, and dry. The above process was repeated four times, and the obtained molecular sieve was dried in an oven at 120°C for 12 hours, and then roasted at a constant temperature of 540°C for 4 hours in a muffle furnace at a rate of 3°C / min. After the calcination, the molecular sieve was ground in a ball mill (Nanjing University Instrument Factory, QM-ISP04) at a speed of 600r / min for 12h to disperse the agglomerated grains, and the particle size after grinding was less than 1 μm. (2) Place the nanometer H-type ZSM-5 molecular sieve prepared in step (1) in a vacuum drying oven at 140° C...

Embodiment 2

[0035] Step is identical with embodiment 1. The difference is that in the preparation step (3) of the organofunctionalized nano molecular sieve, another 0.5 ml of triethylchlorosilane is dissolved in 20 ml of absolute ether; what is obtained is an ethyl modified nanometer HZSM-5 catalyst.

Embodiment 3

[0037] Step is identical with embodiment 1. The difference is that: in the preparation step (3) of the organofunctionalized nano molecular sieve, another 0.5 ml tripropyl chlorosilane is dissolved in 20 ml absolute ether; the n-propyl modified nano HZSM-5 catalyst is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com