Tridax procumbens total flavone preparation method and use thereof

A technology for the production of total flavonoids from Miscanthus flavonoids, which is applied in the field of preparation of total flavonoids from Miscanthus flavonoids, which can solve the problems of troublesome operation, large amount of solvent used, low extraction rate and transfer rate of flavonoids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

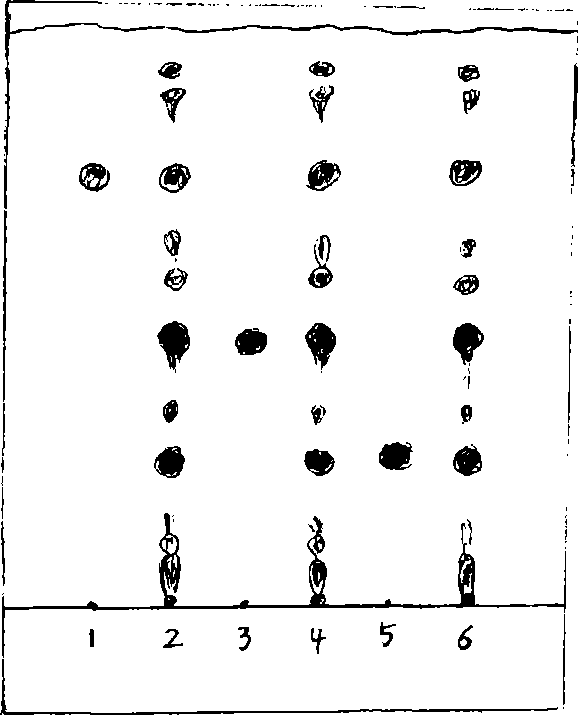

Image

Examples

Embodiment 1

[0025] 1) Raw material processing: crush the whole herb of Pistachio chrysanthemum into coarse powder, and pass through a 40-mesh sieve;

[0026] 2) Extraction: Put the chrysanthemum chrysanthemum powder into the extraction container, put it into an ultrasonic extractor, and use 8 times the amount of 60% aqueous ethanol as a solvent for ultrasonic extraction twice under the condition of 50°C. Each time for 45 minutes, filter with suction, and combine the filtrates;

[0027] 3) Concentration under reduced pressure: Concentrate the filtrate in step 2) with a vacuum film at a water bath temperature below 50° C., recover ethanol, and obtain a concentrated solution;

[0028] 4) Decolorization and degreasing treatment: the concentrated solution of step 3) is ultrasonicated for 40 minutes below 50° C. with powdered activated carbon, the amount of powdered activated carbon is 2% of the weight of Miscanthus coarse powder, suction filtered, activated carbon is removed, and the filtrate ...

Embodiment 2

[0032] In the above step 1): the whole herb of Misantha chrysanthemum is crushed into coarse powder, and passed through a 20-mesh sieve; in the above step 2): the temperature of ultrasonic extraction is 40°C, the time of ultrasonic extraction is 60min, and the amount of hydrous ethanol is 10 times of weight, the concentration of aqueous ethanol is 70%; step 4): in the step 4): the time of ultrasonic decolorization and degreasing treatment is 50min, the consumption of powdered activated carbon is 3% of the weight of the chrysanthemum chrysanthemum powder; in step 6): successively Gradient elution with 20%, 30%, 35%, 55%, 65% aqueous ethanol; the elution flow rate is 15mL·min -1 The diameter-to-height ratio of the chromatographic column is 1:15; the eluent from each part of 30-55% aqueous ethanol is combined; other steps are the same as in Example 1.

Embodiment 3

[0034] In above-mentioned step 2): the temperature of ultrasonic extraction is 60 ℃; Ultrasonic extraction time 30min; 1% of Miscanthus chrysanthemum coarse powder weight; step 6) in: carry out gradient elution with 15%, 25%, 45%, 50%, 60% aqueous ethanol successively; Elution flow rate is 5mL·min -1 ; Merge the eluent of each part of 25-60% aqueous ethanol; Other steps are the same as in Example 1.

[0035] In the above step 2): the temperature of ultrasonic extraction is 45°C, 48°C, 55°C; the time of ultrasonic extraction is 35min, 45min, 55min; the concentration of aqueous ethanol is 55%, 65%. In step 4): the time for ultrasonic decolorization and degreasing treatment is 32 minutes, 35 minutes and 45 minutes. In step 6): the elution flow rate is 6mL min -1 , 12mL·min -1 , 8mL·min -1 . Other steps are the same as in embodiment 1, and can achieve the same technical effect.

[0036] In the above step 2), using 6-8 times the amount of water-containing ethanol as a solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com