Aluminum nitride single-edge nano-comb and method for preparing the same

A nano-comb and aluminum nitride technology, which is applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of aluminum nitride single-sided nano-combs that have not been reported, the process is not easy to control, and the synthesis time is long. The effect of short preparation time, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

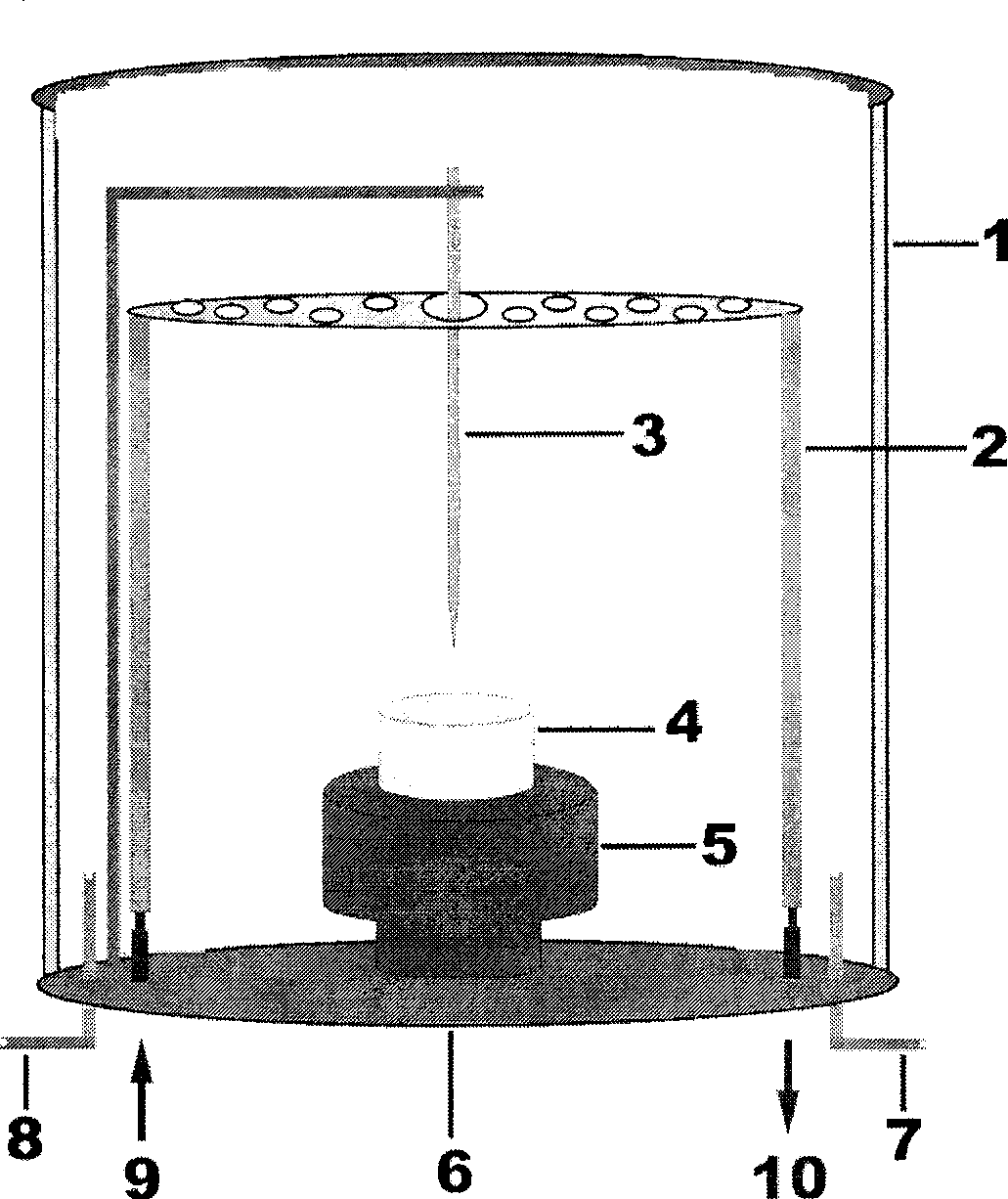

[0022] Example 1 Combined figure 1 A device for preparing nanocombs of the present invention is described.

[0023] figure 1 Among them, 1 is the reaction chamber; 2 is the water-cooled collection wall; 3 is the tungsten cathode, which can be rod-shaped; 4 is the aluminum block; 5 is the anode of the copper pot, and the cathode 3 and the anode 5 are connected to the DC power supply; 6 is the circulating cooling water port , including a water inlet and a water outlet; 7 is a gas mixture inlet; 8 is an air release port, 9 is a water inlet of a water-cooled collection wall, and 10 is a water outlet of a water-cooled collection wall.

[0024] The water-cooled collection wall 2 is used for cooling the reaction, so as to protect the device for preparing the nanocomb.

Embodiment 2

[0025] Example 2 The whole process of preparing AlN single-sided nanocomb.

[0026] First, high-purity Al blocks (purity 99.999%) are put into a copper pot in a reaction chamber of a DC arc discharge device. The anode of the arc discharge device is a copper pot, the cathode is a tungsten electrode with a diameter of 3mm, and the anode is fed with circulating cooling water. The reaction chamber of the DC arc discharge device is evacuated (less than 5 Pa), and then filled with a mixed gas of nitrogen and ammonia (gas purity 99.999%) to 20 kPa. The volume ratio of ammonia in the mixed gas is 5%. After reacting at a voltage of 15V and a current of 80A for 10 minutes, the white powder collected on the anode copper pot and the Al block was an AlN single-sided nanocomb.

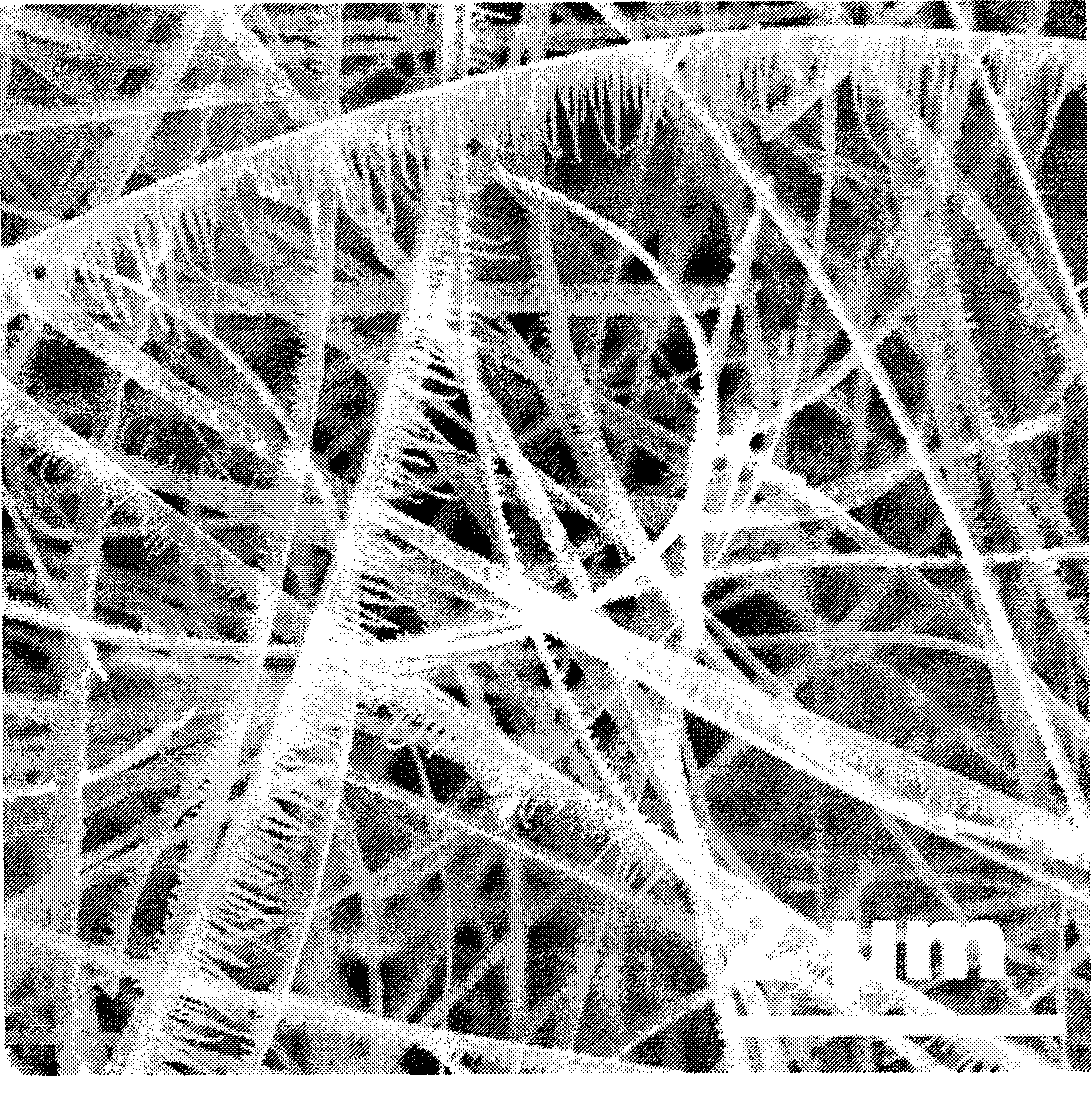

[0027] from figure 2 with image 3 It can be seen that the nanowire array of the unilateral nanocomb structure grows from one side of the middle trunk, while the other side of the trunk is very flat, and no nan...

Embodiment 3

[0029] Example 3 The whole process of preparing AlN single-sided nanocomb.

[0030] First, high-purity Al blocks (purity 99.999%) are put into a copper pot in a reaction chamber of a DC arc discharge device. The anode of the arc discharge device is a copper pot, the cathode is a tungsten electrode with a diameter of 5mm, and the anode is fed with circulating cooling water. The reaction chamber of the DC arc discharge device is evacuated (less than 5 Pa), and then filled with a mixed gas of nitrogen and ammonia (purity 99.999%) to 30 kPa. The volume ratio of ammonia in the mixed gas is 10%. After reacting at a voltage of 30V and a current of 100A for 30 minutes, the white powder collected on the anode copper pot and the Al block was an AlN single-sided nanocomb.

[0031] Image 6 It can be seen from the SEM image that the nanowire array of the unilateral nanocomb structure grows from one side of the middle trunk, while the other side of the trunk is very flat, and no nanowir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com