Processing device of ammoniacal odor and spray liquid and operation method thereof

A treatment device and operation method technology, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve problems such as limiting denitrification and denitrification effects, difficulty in commissioning and management, and increased treatment costs, etc., to achieve odor removal High efficiency, significant denitrification effect, and the effect of reducing the amount of filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

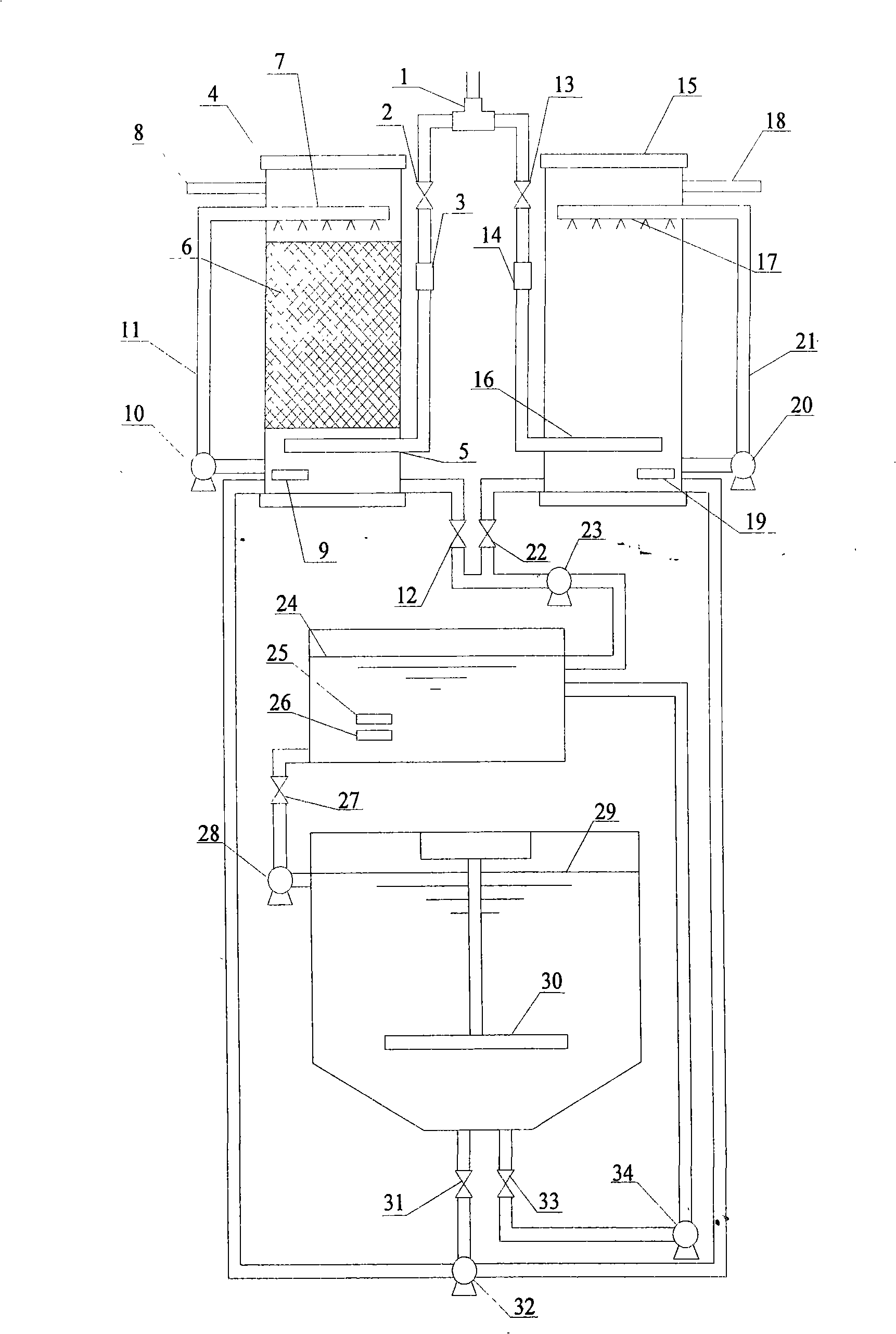

[0027] Embodiment 1: (see figure 1 ) odor enters, the three-way 1 divides the airflow into two parts, and one part enters the biological trickling filter tower 4 through the No. 1 flow control valve 2 and the No. 1 gas flow meter 3. , liquid distributor 7, gas outlet 8, there is a No. 1 NO at the bottom of the tower x -Concentration detector 9, No. 1 circulating pump 10 and No. 1 circulating water pipe 11 connected with the liquid distributor are arranged on the outside, water outlet pipe is provided at the bottom of the tower, equipped with No. 1 valve 12; another part of odor passes through No. 2 flow control valve 13 and The No. 2 gas flowmeter 14 enters the washing tower 15, and the washing tower includes a gas distributor 16, a liquid distributor 17, and a gas outlet 18. The bottom of the tower is provided with a No. 1 ammonia-nitrogen concentration detector 19, and No. 2 circulation pump 20 and liquid distributor are arranged outside. The No. 2 circulating water pipe 2...

Embodiment 2

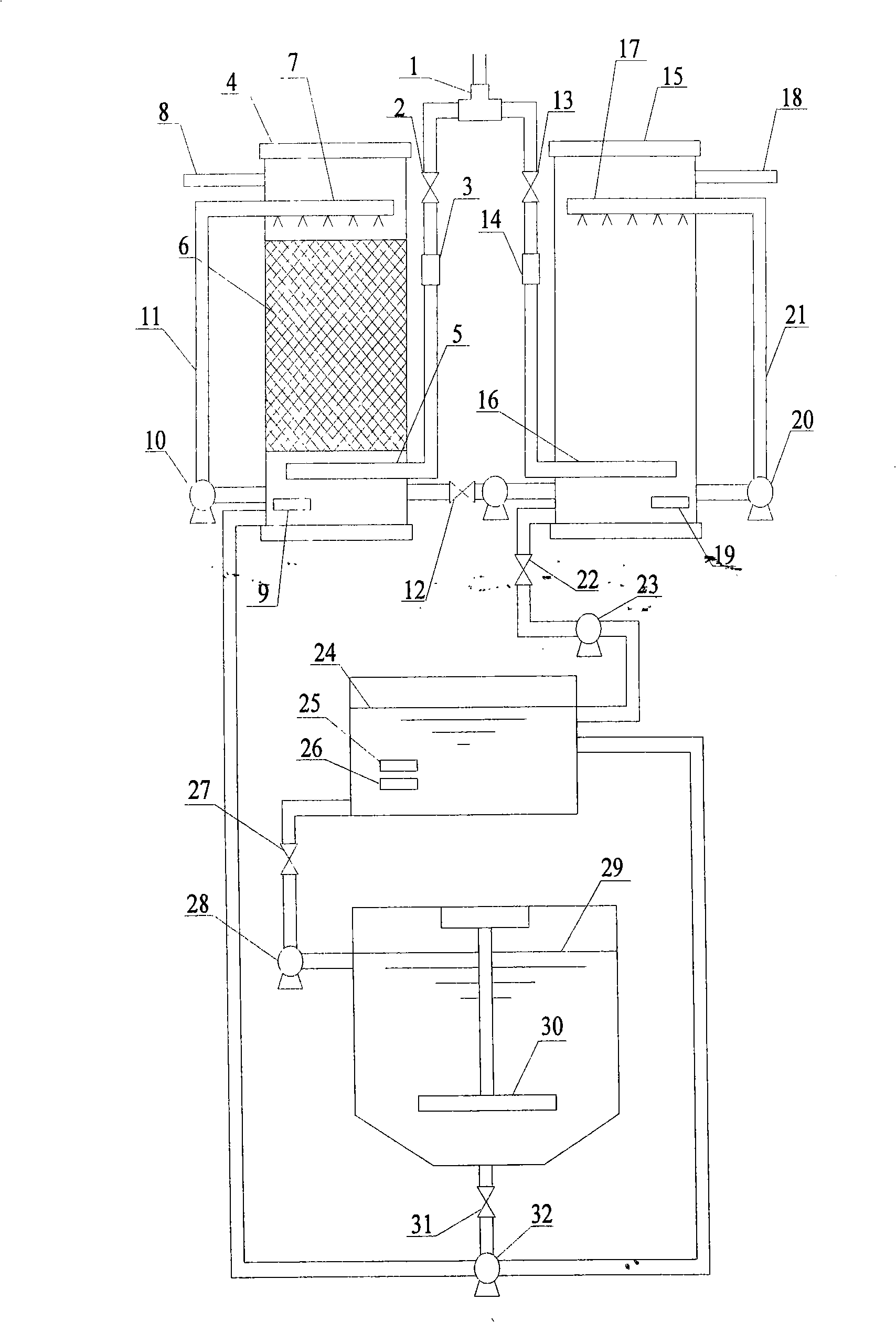

[0033] Embodiment 2: (see figure 2 ) The difference between this embodiment and Embodiment 1 is that the effluent of the biological trickling filter tower 4 is passed into the scrubber 15 (in series), and enters the liquid distributor 17 through the circulating pump 20 and the circulating water pipe 21 as the scrubber spray water. And ASBR29 effluent no longer enters the washing tower. The water volume ratio of the ASBR backflow to the biotrickling filter tower and the mixing adjustment tank is 1:1.5-2.5.

[0034] In this embodiment, the effluent of the biological trickling filter is used as the spray water of the washing tower, which is mainly because the effluent of the biological trickling filter contains NO x - The concentration is high, the concentration of ammonia nitrogen is low, and the water is weakly acidic, which is very suitable as the spray water of the washing tower. After the washing tower is drained, the effluent of the biological trickling filter is inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com