Method for preparing boron nitride nano-tube

A technology of boron nitride nanotubes and nitrogen gas, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of diverse structures and low purity of BN nanotubes, and achieve simple preparation process, mild reaction conditions, thickness uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

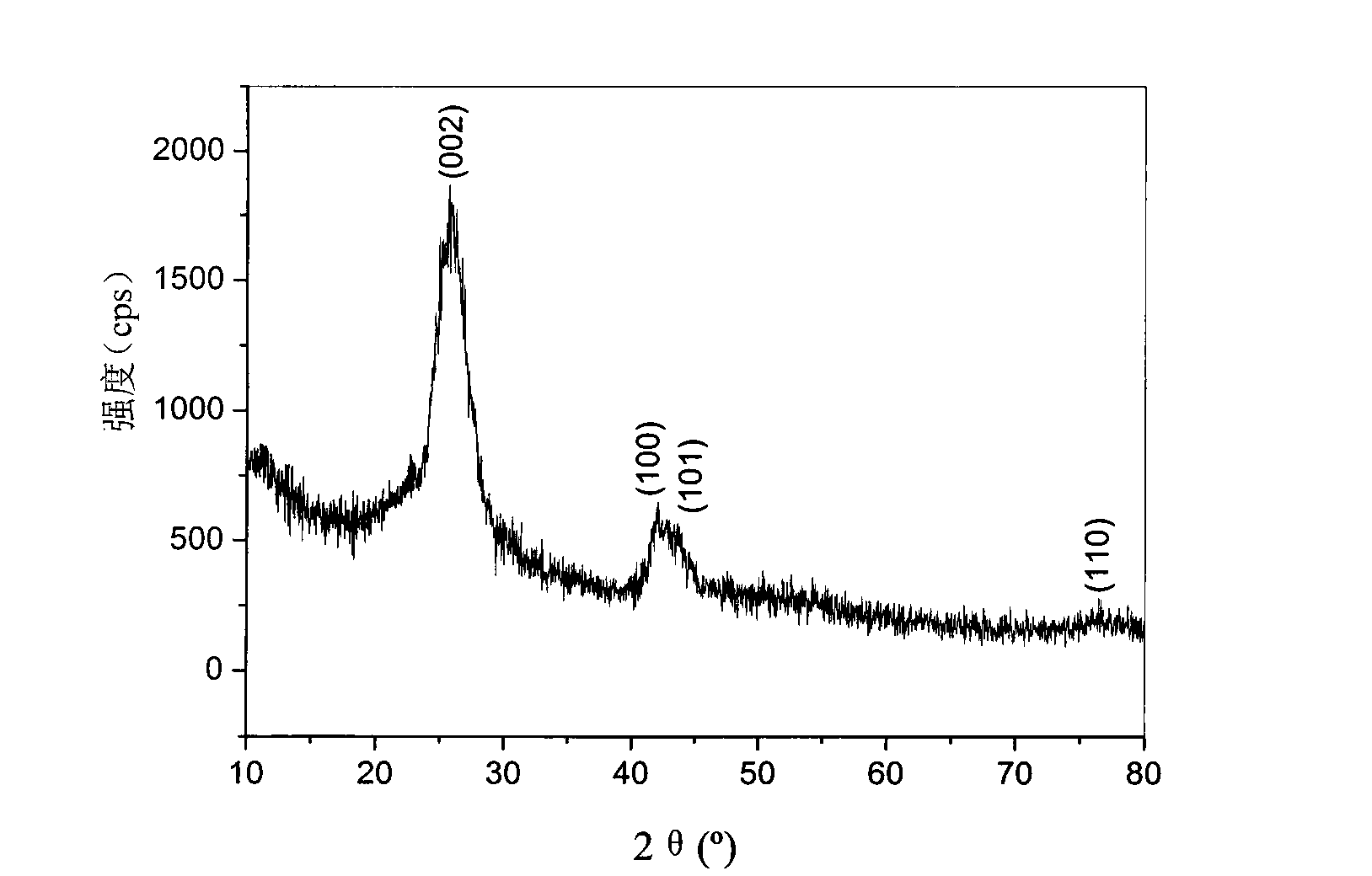

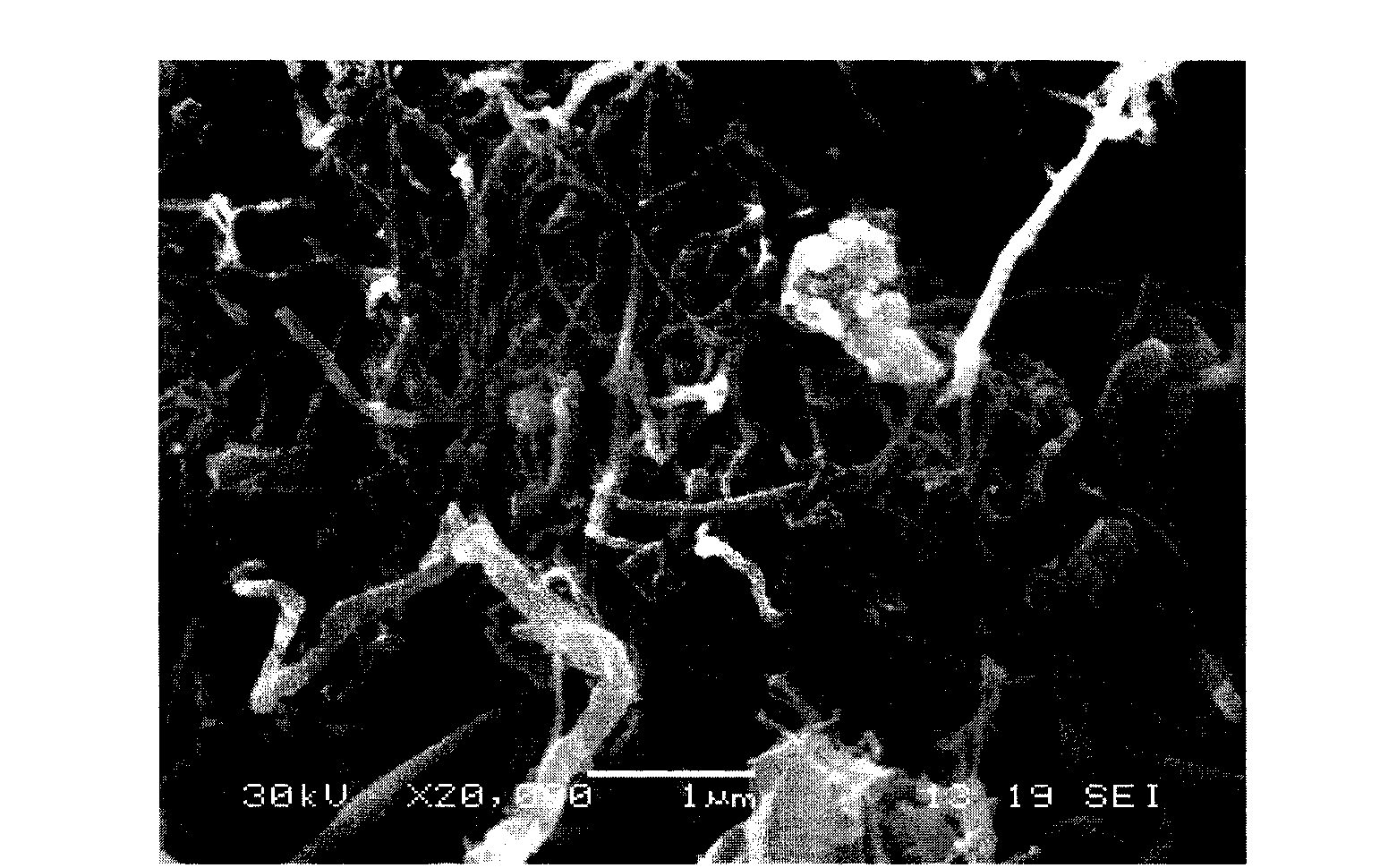

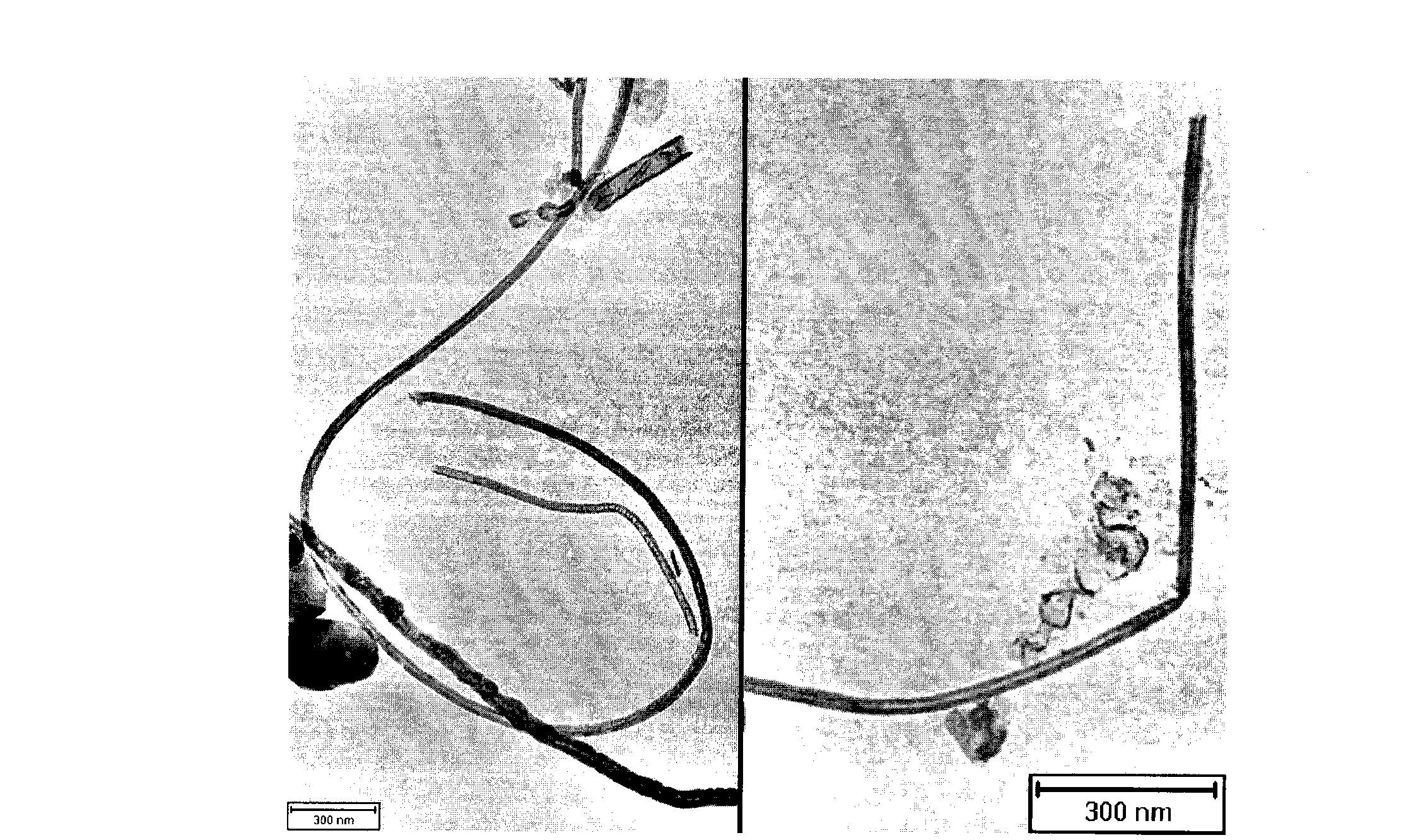

[0025] Take 7.05 grams of Ca(OH) 2 , 19.9 g B 2 o 3 , 23.15 grams of magnesium powder and 0.52 grams of Co 2 o 3 , put it into the reaction boat after mixing thoroughly, put it in a tube furnace, and react in an ammonia atmosphere at 950°C for 24 hours, keep the gas flux at 0.1L / min, cool down to 600°C with the furnace, and switch to argon to prevent BN oxidation. Add distilled water and 36wt.% hydrochloric acid to the product according to the reaction ratio, heat and stir at 50°C for 24 hours, dissolve impurities and metals in the product, filter with suction and wash several times, and dry in vacuum at 80°C for 24 hours to obtain 12.34 grams of white powder , with B 2 o 3 The yield was calculated as 87% based on the calculation. The product is analyzed by XRD, SEM, TEM, HRTEM and FTIR, which proves that the product is a relatively pure BN nanotube with a BN nanotube content of more than 85%. 90μm, diameter 17-21nm, average about 20nm, wall thickness 5-7nm, average 6n...

Embodiment 2

[0032] Take 7.58 grams of CaO, 28.28 grams of B 2 o 3 , 32.90 grams of magnesium powder and 0.85 grams of Co 2 o 3 , put it into the reaction boat after mixing thoroughly, put it in a tube furnace, and react in a nitrogen atmosphere at 600°C for 48 hours, keep the gas flux at 2.5L / min, cool down to 500°C with the furnace, and switch to argon to prevent BN oxidation. Add distilled water and 38wt.% hydrochloric acid to the product according to the reaction ratio, heat and stir at 80°C for 12 hours, dissolve impurities and metals in the product, filter with suction and wash several times, and vacuum dry at 80°C for 12 hours to obtain 17.73 grams of white powder , with B 2 o 3 The yield was calculated as 87.9% based on the calculation. The product is analyzed by XRD, SEM, TEM, HRTEM and FTIR, which proves that the product is a relatively pure BN nanotube with a BN nanotube content of more than 90%. ; Diameter 15-20nm, average about 22nm, wall thickness 5-10nm, average about...

Embodiment 3

[0034] Take 7.51 grams of Ca(OH) 2 , 36.10 g H 3 BO 3 , 23.51 grams of magnesium powder and 0.65 grams of Fe 2 o 3 , put it into the reaction boat after mixing thoroughly, put it in a tube furnace, and react in a nitrogen atmosphere at 1000°C for 48 hours, keep the gas flux at 5L / min, cool down to 600°C with the furnace, and switch to argon to prevent BN oxidation . Add distilled water and 38wt.% hydrochloric acid to the product according to the reaction ratio, heat and stir at 80°C for 12 hours, dissolve impurities and metals in the product, filter with suction and wash several times, and dry in vacuum at 80°C for 12 hours to obtain 12.41 grams of white powder , with H 3 BO 3 The yield was calculated as 82.7% as a benchmark. The product is analyzed by XRD, SEM, TEM, HRTEM and FTIR, which proves that the product is a relatively pure BN nanotube with a BN nanotube content of over 90%. ; Diameter 15-20nm, average about 22nm, wall thickness 5-10nm, average about 7nm, unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com