Production process for comprehensively utilizing eupatorium adenophorum

A technology for the production of Echinacea, which is applied in the petroleum industry, biofuels, special forms of dry distillation, etc., can solve the problems of igniting dry slag, consuming manpower and funds, and long production cycle, reducing burning raw materials and saving energy. The effect of improving production costs and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

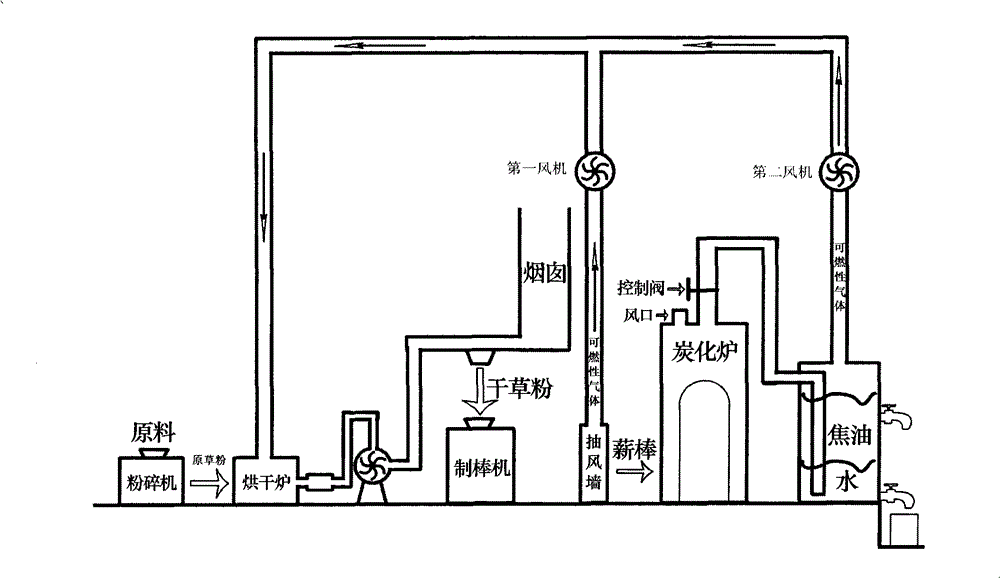

[0072] The detailed production process of the comprehensive utilization of Eupatorium adenophorum is as follows:

[0073] Firstly, the whole plant of Eupatorium adenophorum is dried in the sun, then the dried plant is cut into grass sections with a length of 4 cm, and crushed by a pulverizer to obtain raw grass powder; then the raw grass powder is sent to a drying oven for drying to obtain hay powder; then feed the hay powder into the rod making machine, when the temperature in the rod making machine reaches 200-400°C, the hay powder is hot-pressed into a fuel rod, and the CO and other gases generated during this process are drawn back through the exhaust wall for drying. The drying furnace participates in the combustion, thereby saving the combustion raw materials of the drying furnace and saving costs.

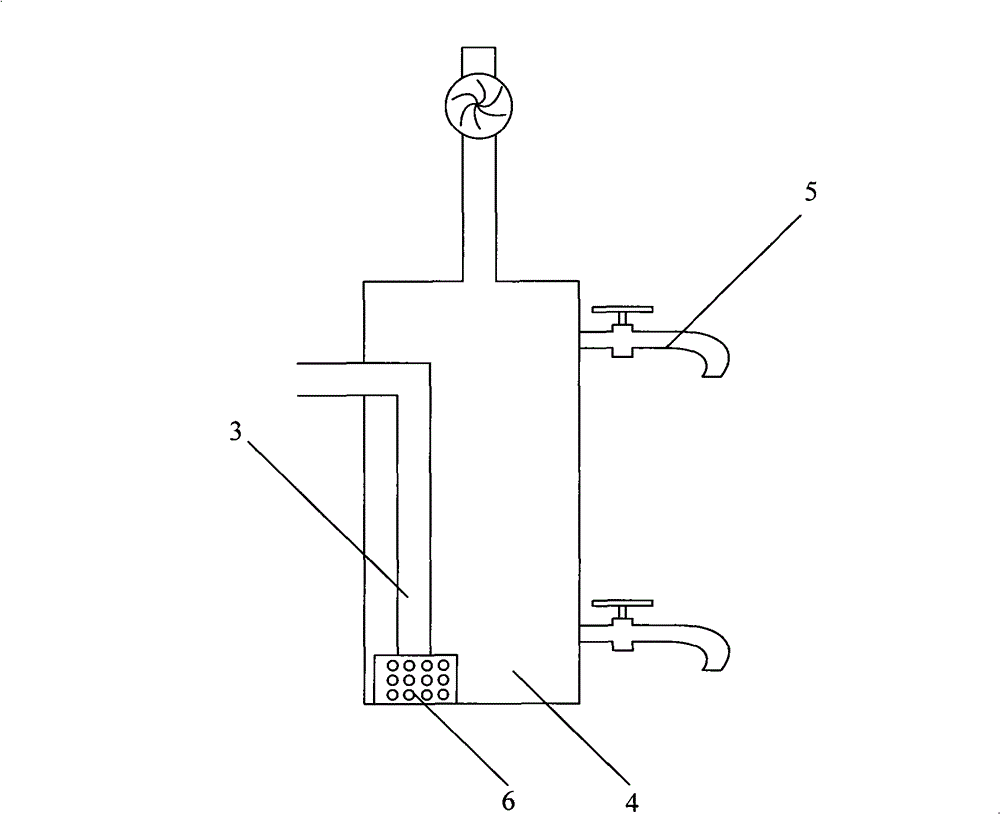

[0074] After the shaped rod comes out of the rod outlet of the rod making machine, it is sent into the carbonization furnace to start the carbonization process. When laying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com