Method for preparing composite charged mosaic membrane via interfacial polymerization

A technology of interfacial polymerization and charged mosaic, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of backward nanofiltration membrane preparation technology of charged mosaic membrane, no industrial membrane modules, membrane production Harsh process conditions and other issues, to achieve good interception capacity, good permeability, and facilitate industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

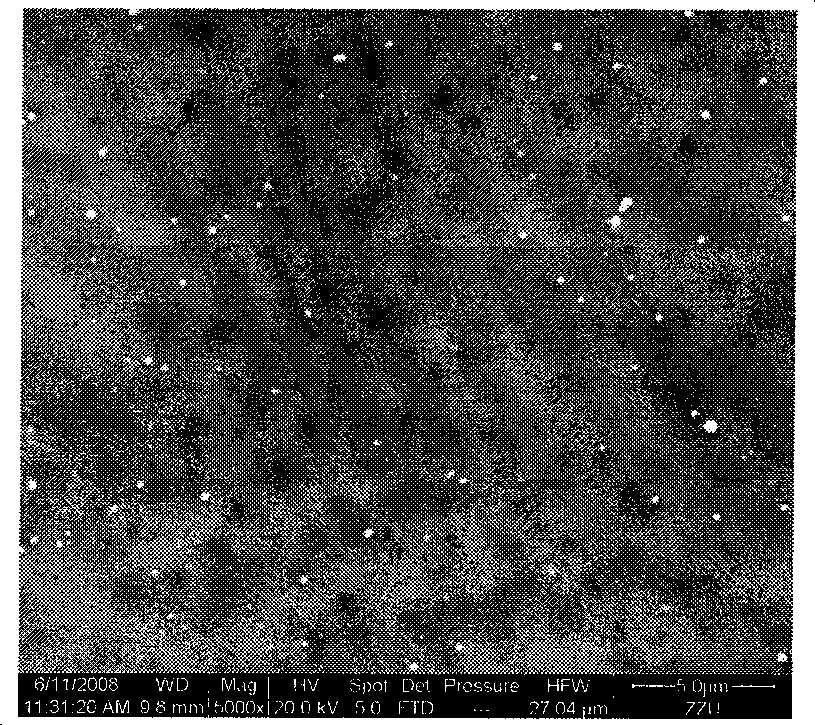

[0041] The polysulfone ultrafiltration membrane is used as the supporting membrane, the mixed aqueous solution of polyethyleneimine (PEI) and 2,5-diaminobenzenesulfonic acid (DIA) is used as the inorganic phase, and the n-hexane solution of trimesoyl chloride (TMC) As the organic phase, a composite charged mosaic film was prepared by interfacial polymerization. Proceed as follows:

[0042] (1) Select polysulfone (PS) flat ultrafiltration membrane as base membrane (water flux is 200-300L m -2 h -1 · bar -1 , cut molecular weight is about 50000-80000);

[0043] (2) prepare inorganic phase solution, the mass percent concentration of PEI is 1.0% in the inorganic phase solution; The mass percent concentration of DIA is 1.0%; Sodium carbonate mass percent concentration is 0.2%, sodium bicarbonate mass percent concentration is 0.1%; the mass percent concentration of sodium lauryl sulfate is 0.1%. Introduce the inorganic phase solution on the surface of the dense layer of the ult...

Embodiment 2

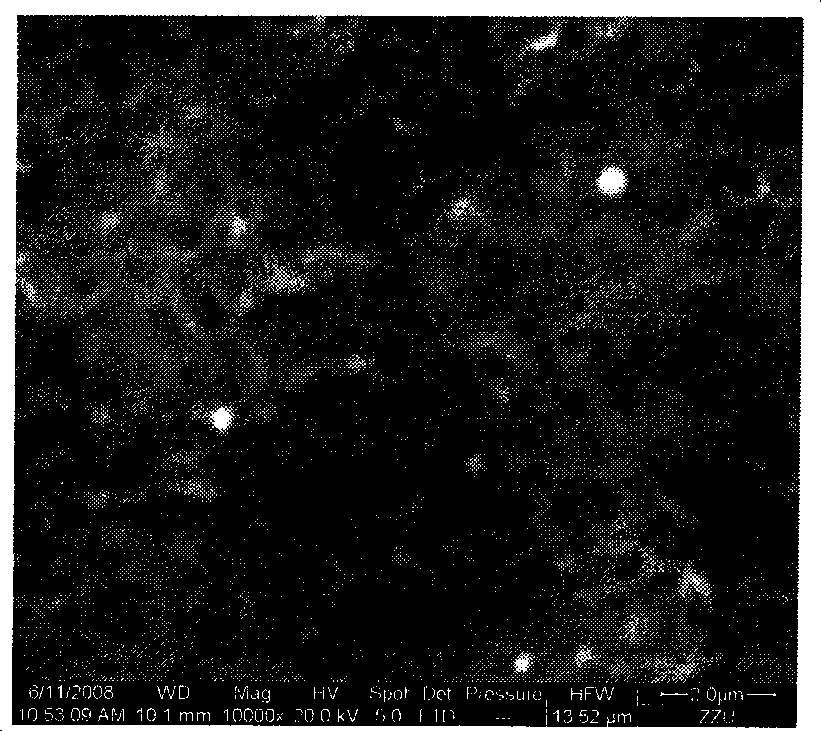

[0060] The polyethersulfone (PES) flat ultrafiltration membrane is used as the base membrane, the mixed aqueous solution of polyepichlorohydrin amine (PECH-amine) and DIA is used as the inorganic phase, and the n-hexane solution of TMC is used as the organic phase. Electrical mosaic film.

[0061] Referring to Example 1 step, take polyethersulfone (PES) flat ultrafiltration membrane as base membrane (water flux is 100-150L m -2 h -1 · bar -1 , the cutting molecular weight is about 10000-20000), the mass percentage concentration of polyepichlorohydrin amine (PECH-amine) in the inorganic phase solution is 1.2%; the mass percentage concentration of DIA is 1.4%; the sodium carbonate concentration mass percentage The concentration is 0.1%; the mass percent concentration of TMC in the organic phase is 1.0%; the interfacial polymerization time is 180s. After the interfacial polymerization, the composite film is placed in a vacuum drying oven and heat-treated at 80-110°C for 10min , ...

Embodiment 3

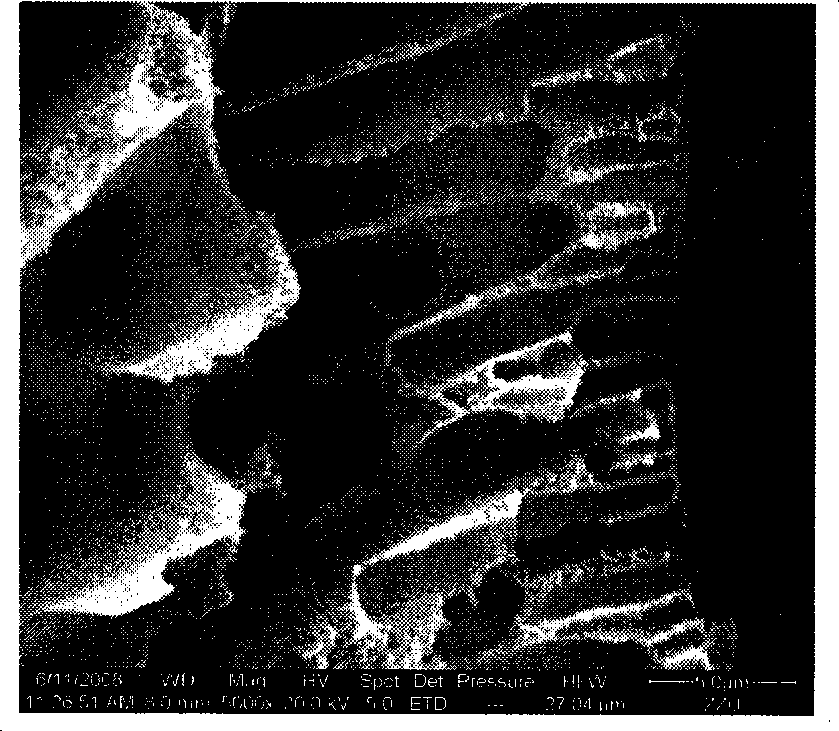

[0067] The polyethersulfone hollow fiber ultrafiltration membrane is used as the supporting membrane, the mixed aqueous solution of polyethyleneimine (PEI) and 2,5-diaminobenzenesulfonic acid (DIA) is used as the inorganic phase, and the n-hexane solution of TMC is used as the organic phase , to prepare composite charge-mosaic membranes by interfacial polymerization.

[0068] With reference to the steps of Example 1, using polyethersulfone (PES) hollow fiber ultrafiltration membrane as the supporting membrane (the inner diameter of the membrane is 0.630mm, the membrane thickness is 0.350mm and the molecular weight cut-off is 50000-80000), the mass percentage concentration of PEI in the inorganic phase solution 0.85%; the mass percentage concentration of DIA is 0.75%; the mass percentage concentration of acid acceptor is 0.3%, and the ratio of sodium carbonate and sodium bicarbonate is 1:2; the mass percentage concentration of surfactant is 0.1%; in the organic phase The mass p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water flux | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com