Polymer carbon nano tube compound structure and preparation method thereof

A carbon nanotube composite and carbon nanotube technology, which is applied in the field of polymer carbon nanotube composite structure and its preparation, can solve the problems of product instability and weak non-covalent bond force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

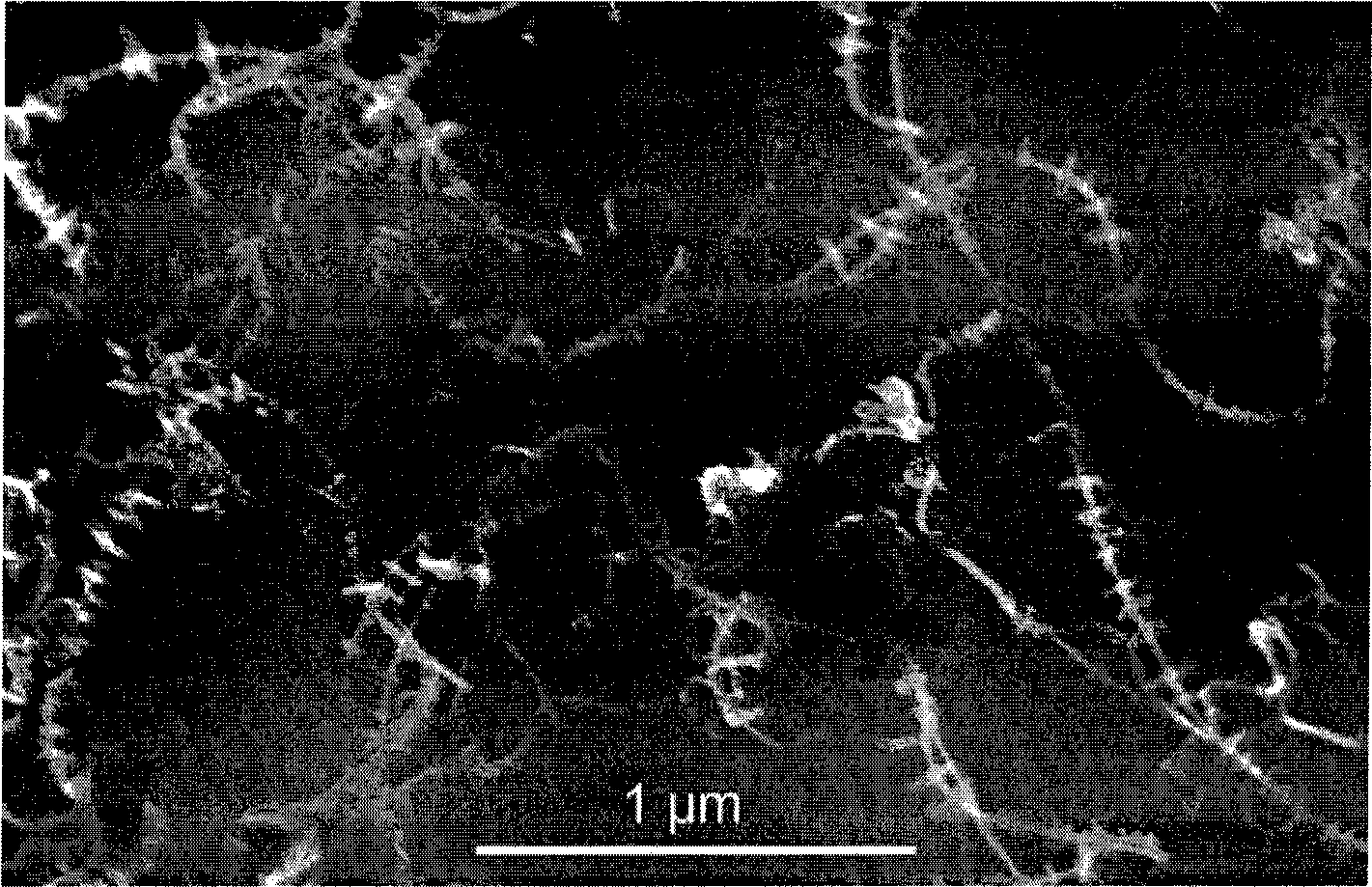

[0016] Weigh 1 mg of single-walled carbon nanotubes and add them to a test tube containing 3 ml of o-dichlorobenzene, and ultrasonicate for 3 h; at the same time, weigh 2 mg of high-density polyethylene and add them to a test tube containing 10 ml of o-dichlorobenzene Dissolve in a constant temperature oil bath set at 140°C; add the ultrasonically treated single-walled carbon nanotube suspension into the polyethylene solution, and keep the temperature at 140°C for 10 minutes; take out the mixed solution and let it cool down to room temperature naturally; filter and dry That is, a solid product is obtained. The SEM analysis spectrum of polyethylene / single-walled carbon nanotube composite structure is as follows figure 1 shown.

[0017] from figure 1 It can be seen that polyethylene platelets form a periodic arrangement on the surface of the single-walled carbon nanotubes, completely wrap the carbon nanotubes, and the carbon nanotubes are separated from each other.

[0018] T...

Embodiment 2

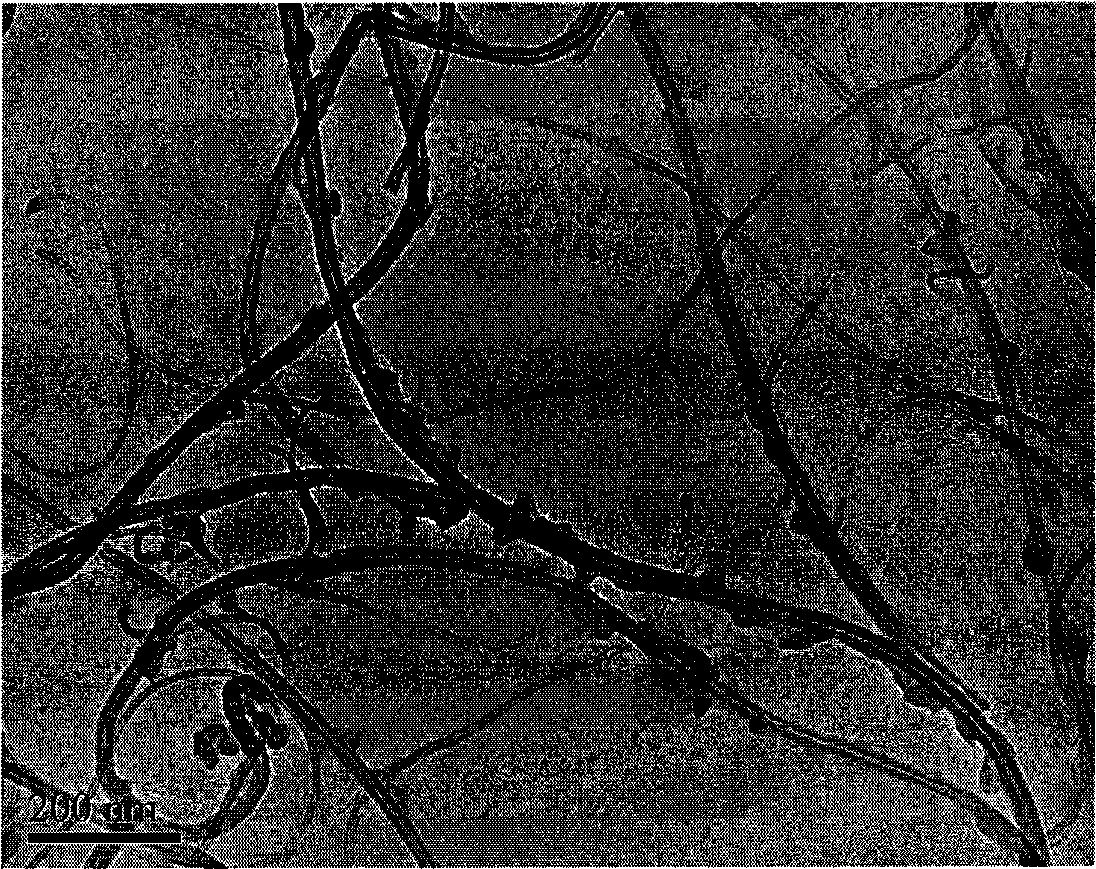

[0020] Weigh 1 mg of multi-walled carbon nanotubes and add them to a test tube containing 3 ml of dimethyl sulfoxide, sonicate for 3 hours; at the same time weigh 2 mg of polybutylene terephthalate and add them to a test tube containing 10 ml of dimethyl sulfoxide , placed in a constant temperature oil bath set at 240°C to dissolve; add the multi-walled carbon nanotube suspension after ultrasonic treatment into the polybutylene terephthalate solution, and keep the temperature at 240°C for 10 minutes; take out The mixed solution was allowed to cool down to room temperature naturally; the solid product was obtained by filtering and drying.

[0021] The TEM analysis spectrum of polybutylene terephthalate / multi-walled carbon nanotube composite structure is as follows image 3 shown, from image 3 It can be seen that the surface of the multi-walled carbon nanotubes is covered with a layer of polybutylene terephthalate, which also has good dispersion in xylene.

Embodiment 3

[0023] Weigh 1 mg of multi-walled carbon nanotubes and add them to a test tube containing 3 ml of o-dichlorobenzene, and ultrasonically treat them for 3 h; at the same time, weigh 2 mg of polypropylene and add them to a test tube containing 10 ml of o-dichlorobenzene, and set the temperature at Dissolve in a constant temperature oil bath at 180°C; add the multi-walled carbon nanotube suspension after ultrasonic treatment to the polypropylene solution, and keep the temperature at 180°C for 10 minutes; take out the mixed solution and let it cool down to room temperature naturally; filter and dry to obtain solid product.

[0024] The HR-TEM analysis spectrum of polypropylene / multi-walled carbon nanotube composite structure is as follows Figure 4 shown, from Figure 4 It can be seen that the surface of the multi-walled carbon nanotubes is covered with a layer of polypropylene, which has good dispersion in p-xylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com