Fire-resistant micro-metal brake pad

A technology of brake pads and high temperature resistance, applied in the field of automobile brake pads, can solve the problems of large damage to brake drums or brake discs, easy corrosion of semi-metallic brake pads, high thermal conductivity, etc. Slow heating and good comfort performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Put wollastonite fiber 10% and E glass short fiber 9% into an oven by weight percentage, heat at 350 ° C for 15 minutes, then pour it into a high-speed disperser, and then according to the weight ratio to the above mixture is Pour the aqueous solution of KH-550 silane coupling agent (γ-aminopropyltriethoxysilane) with a mass concentration of 1.0% into a high-speed disperser in a ratio of 1:1, control the temperature at 150 ° C, and stir at a high speed for 25 After a few minutes, take out the mixture and dry it for later use.

[0018] Then, by weight percentage, nitrile rubber powder (100-150 mesh) 2%, tire powder (60-80 mesh) 6%, expanded graphite 3%, ultrafine iron oxide powder 8%, chromite powder (300-350 mesh) 3%, magnetite 3%, diatomite 8%, crushed steel fiber 6%, viscose fiber (length 1-2mm) 8%, aluminum silicate hollow sphere 1%, heavy magnesium oxide 3%, Zinc stearate 0.5%, copper sulfide powder 0.5%, calcined petroleum coke 5%, barite powder (500-60...

Embodiment 2

[0019] Example 2: Put wollastonite fiber 7% and E glass short fiber 6% into an oven by weight percentage, heat at 350 ° C for 20 minutes, then pour it into a high-speed disperser, and then according to the weight ratio to the above mixture is Pour the aqueous solution of KH-550 silane coupling agent (γ-aminopropyltriethoxysilane) with a mass concentration of 0.5% into a high-speed disperser in a ratio of 1:1, control the temperature at 180 ° C, and stir at a high speed for 20 After a few minutes, take out the mixture and dry it for later use.

[0020] Then, by weight percentage, nitrile rubber powder (100-150 mesh) 4%, tire powder (60-80 mesh) 3%, expanded graphite 5%, ultrafine iron oxide powder 4%, chromite powder (300-350 mesh) 6%, magnetite 5%, diatomite 5%, crushed steel fiber 9%, viscose fiber (length 1-2mm) 12%, aluminum silicate hollow sphere 0.5%, heavy magnesium oxide 2%, Zinc stearate 0.3%, copper sulfide powder 0.5%, calcined petroleum coke 3%, barite powder (500-...

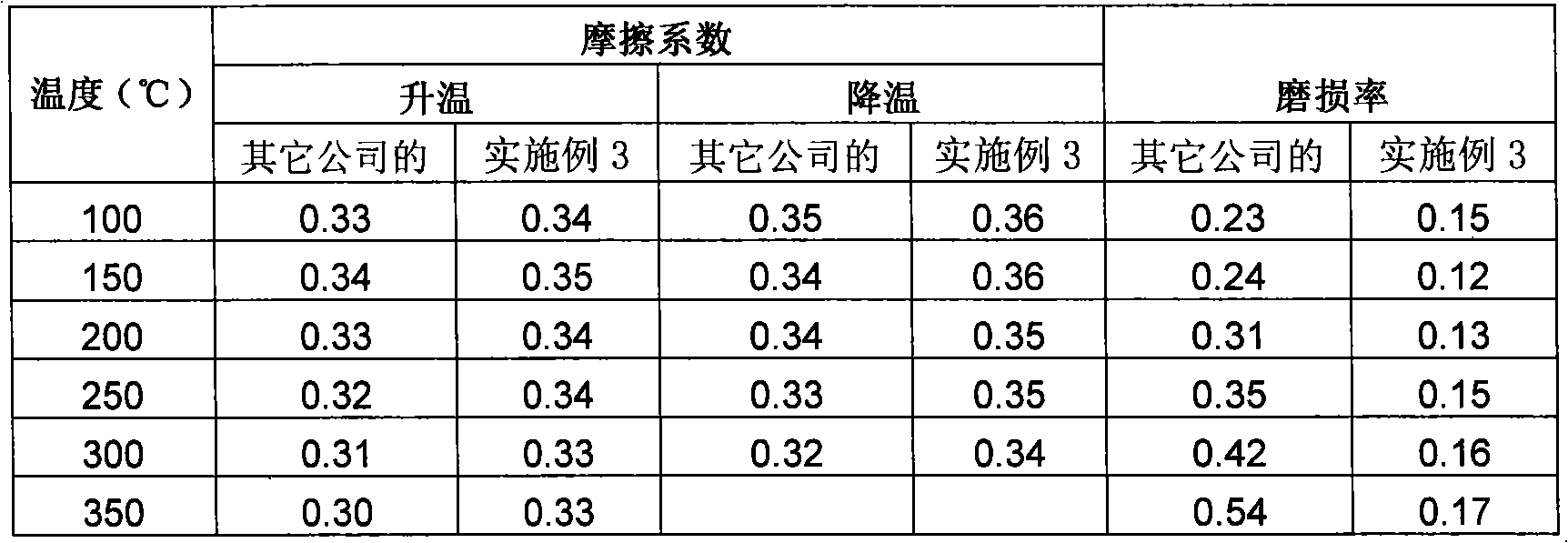

Embodiment 3

[0021] Example 3: Put wollastonite fiber 8% and E glass short fiber 7% into an oven by weight percentage, heat at 360 ° C for 18 minutes, then pour it into a high-speed disperser, and then according to the weight ratio to the above mixture is Pour the aqueous solution of KH-550 silane coupling agent (γ-aminopropyltriethoxysilane) with a mass concentration of 0.8% into a high-speed disperser at a ratio of 1:1, control the temperature at 160 ° C, and stir at a high speed for 22 After a few minutes, take out the mixture and dry it for later use.

[0022] Then, by weight percentage, nitrile rubber powder (100-150 mesh) 3%, tire powder (60-80 mesh) 5%, expanded graphite 4%, ultrafine iron oxide powder 6%, chromite powder (300-350 mesh) 5%, magnetite 5%, diatomite 7%, crushed steel fiber 7%, viscose fiber (length 1-2mm) 9%, aluminum silicate hollow sphere 0.8%, heavy magnesium oxide 3%, Zinc stearate 0.4%, copper sulfide powder 0.8%, calcined petroleum coke 4%, barite powder (500-6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com