Method and device for preparing tin dioxide nano-belt through vapor deposition

A tin dioxide and vapor deposition technology, applied in low-dimensional nanomaterials and nanometer fields, can solve the problems of poor sample crystallinity, complex process conditions, and high operational level requirements, achieving low cost, simple process, and high industrialization value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

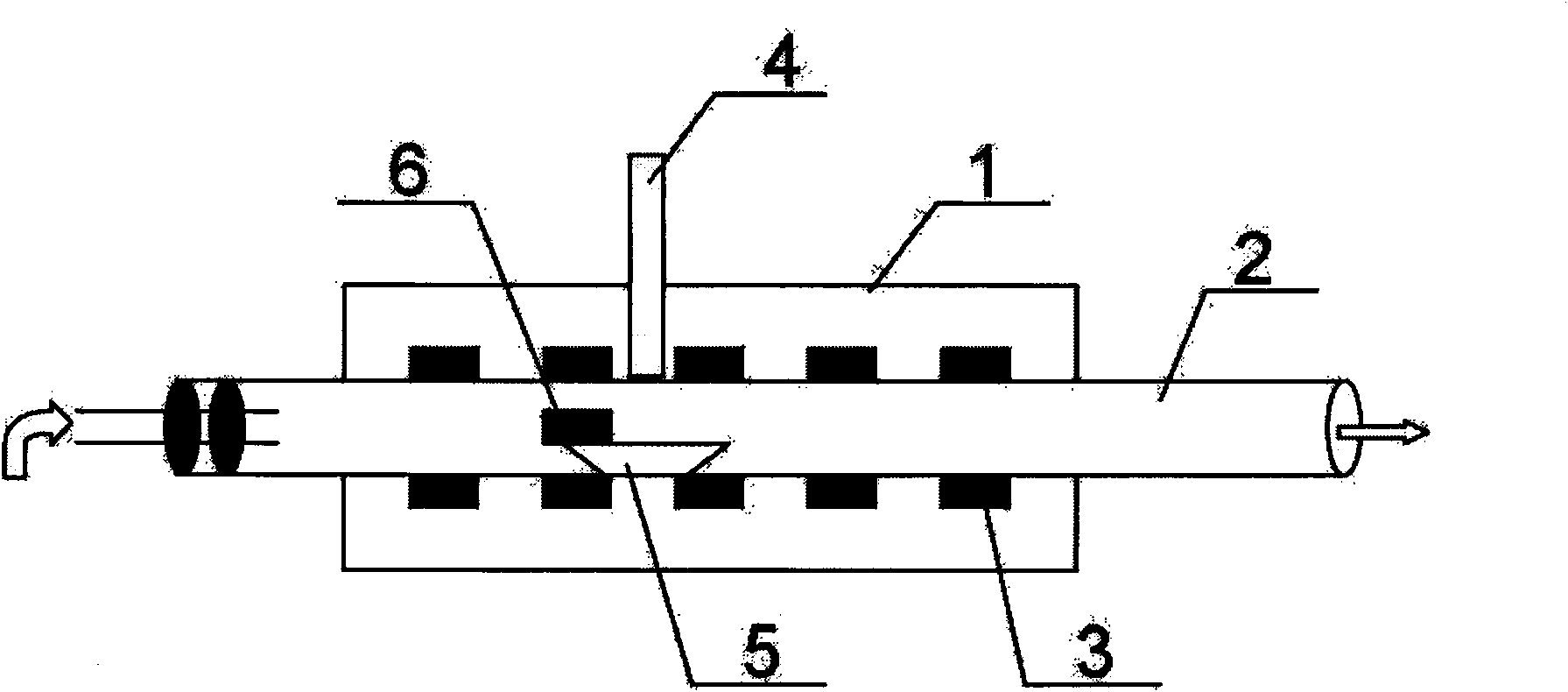

[0032] Such as figure 1 Shown vapor deposition prepares the device of tin dioxide nanobelt, and this device is made up of tubular resistance furnace 1, ceramic boat 5 and silicon sheet 6, is provided with quartz tube 2, heating in conventional prior art in tubular resistance furnace 1 The rod 3 and the thermocouple 4 are special in that a ceramic boat 5 containing samples is placed in the heating zone of the quartz tube 2 in the tubular resistance furnace 1, and a silicon chip 6 facing down is placed on the ceramic boat 5.

[0033] Utilize above-mentioned device, the method step of preparing tin dioxide nanoribbon by gas phase deposition:

[0034] (1) 7.01g SnCl 4 ·5H 2 O (mass purity 99.0%), 25.21g citric acid monohydrate (mass purity 99.5%), and ethylene glycol (volume purity 99.0%) of 13.5ml were mixed and dissolved in 30ml deionized water and stirred to form a solution;

[0035] (2) The 30ml solution of the ingredients in step (1) was heated in a 150ml Erlenmeyer flask ...

Embodiment 2

[0040] The test device is the same as in Example 1.

[0041] Utilize above-mentioned device, the method step of preparing tin dioxide nanoribbon by gas phase deposition:

[0042] (1) 2.28g SnCl 2 2H 2 O (mass purity 99.0%), 12.6g citric acid monohydrate (mass purity 99.5%), and 10.1ml of ethylene glycol (volume purity 99.0%) were mixed and dissolved in 20ml deionized water and stirred to form a solution;

[0043] (2) The 20ml solution of the ingredients in step (1) was heated in a 150ml Erlenmeyer flask at 60°C and stirred (100r / min) for 2 hours to obtain a sol, and then the gel was obtained at a constant temperature of 100°C for 15 hours. The glue was cracked at a constant temperature of 350°C for 5 hours to obtain an amorphous C-Sn-O composite precursor, which was ground into powder with a mortar for later use;

[0044](3) The powder product that step (2) obtains moves in the ceramic boat 5, then moves to the heating zone in the quartz tube 2 of tubular resistance furnace...

Embodiment 3

[0048] The test device is the same as in Example 1.

[0049] Utilize above-mentioned device, the method step of preparing tin dioxide nanoribbon by gas phase deposition:

[0050] (1) 17.71g SnCl 4 ·5H 2 O (mass purity 99.0%), 42.02g citric acid monohydrate (mass purity 99.5%), and 15.2ml of ethylene glycol (volume purity 99.0%) were mixed and dissolved in 50ml deionized water and stirred to form a solution;

[0051] (2) The 50ml solution of the ingredients in step (1) was heated in a 150ml Erlenmeyer flask at 100°C and stirred (rotating at 200r / min) for 0.5h to obtain a sol, and then kept at a constant temperature of 250°C for 6h to obtain a gel. The gel was cracked at a constant temperature of 500°C for 0.5h to obtain an amorphous C-Sn-O composite precursor, which was ground into powder with a mortar for later use;

[0052] (3) The powder product that step (2) obtains moves in the ceramic boat 5, then moves to the heating zone in the quartz tube 2 of tubular resistance fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com