Method for preparing high viscosity lubricating oil

A lubricating oil and high-viscosity technology, which is applied in the direction of lubricating compositions, petroleum industry, base materials, etc., can solve the problems of no description, large amount of catalyst, etc., and achieve the effects of low pour point, high catalytic activity, and high single-pass conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

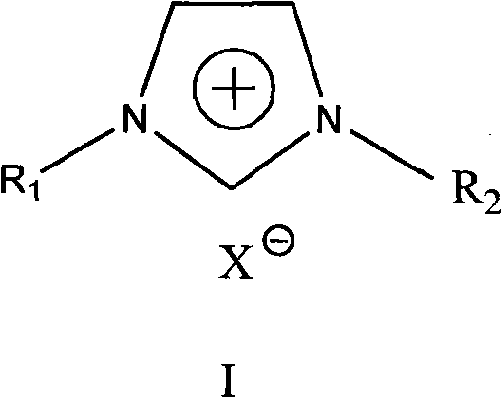

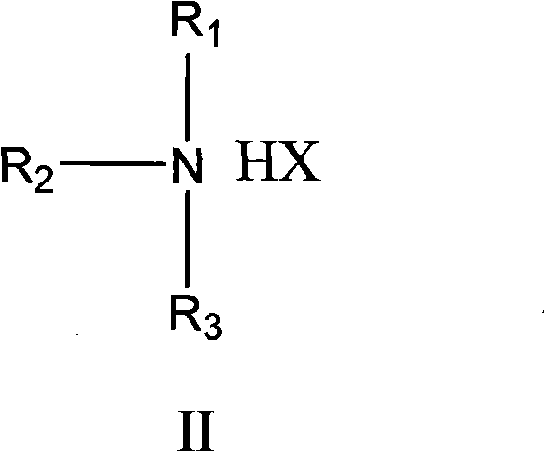

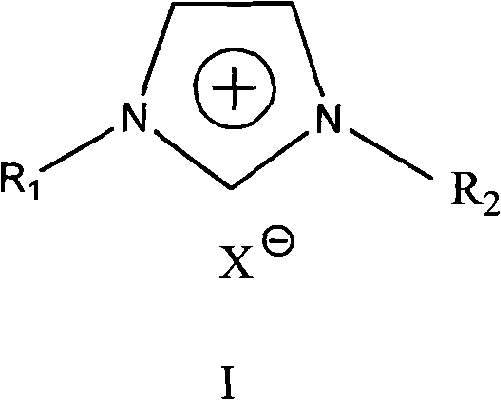

Method used

Image

Examples

Embodiment 1

[0026] In a clean and dry 200ml agitated autoclave, add 120ml of 1-decene and 20ml of cyclohexane, heat to 80°C, add 2.0g of aluminum trichloride while stirring, and then add 2.0g of trimethylamine hydrochloride , and finally add 0.5g ferric chloride. Pressurize to 1.0Mpa with nitrogen, stir vigorously, and react at 130°C for 30 minutes. After the reaction was finished, the product was left standing in a separatory funnel, and the product was divided into two layers, the lower layer being the ionic liquid, and the upper layer being the organic phase. After separation, the organic phase is washed with water to remove a small amount of dissolved catalyst. The organic phase was distilled off under reduced pressure to remove 1-decene as the reaction to obtain polyalphaolefin oil with a yield of 78% and a kinematic viscosity of 190.36mm at 40°C. 2 / s, the kinematic viscosity at 100°C is 28.25mm 2 / s, the viscosity index is 187.

Embodiment 2

[0028] The experimental method is the same as in Example 1, except that 0.5 g of tin chloride as a procatalyst is added. Obtain polyalpha-olefin oil, yield 81%, 40 ℃ kinematic viscosity is 240.87mm 2 / s, the kinematic viscosity at 100°C is 31.43mm 2 / s, the viscosity index is 173.

Embodiment 3

[0030]In a clean and dry 200ml agitated autoclave, add 20ml of 1-decene, 20ml of 1-octene, and 20ml of 1-dodecene, heat to 80°C, add 2.0g of aluminum trichloride while stirring, and then add three Ethylamine hydrochloride 2.0g, finally add 0.5g tin chloride. Pressurize to 1.0Mpa with nitrogen, stir vigorously, and react at 130°C for 30 minutes. After the reaction was finished, the product was left standing in a separatory funnel, and the product was divided into two layers, the lower layer being the ionic liquid, and the upper layer being the organic phase. After separation, the organic phase is washed with water to remove a small amount of dissolved catalyst. The organic phase was distilled off under reduced pressure to remove the reacted 1-decene to obtain polyalphaolefin oil with a yield of 75% and a kinematic viscosity of 253.66mm at 40°C. 2 / s, the kinematic viscosity at 100°C is 34.25mm 2 / s, the viscosity index is 182.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com