Treatment method of magnesium or magnesium alloy surface

A treatment method and technology for magnesium alloys, applied in the direction of metal material coating process, etc., can solve the problems of excessive degradation speed, local pH increase, loss of mechanical properties of magnesium and its magnesium alloys, etc. Effects of reduced mechanical property loss, improved corrosion resistance and biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

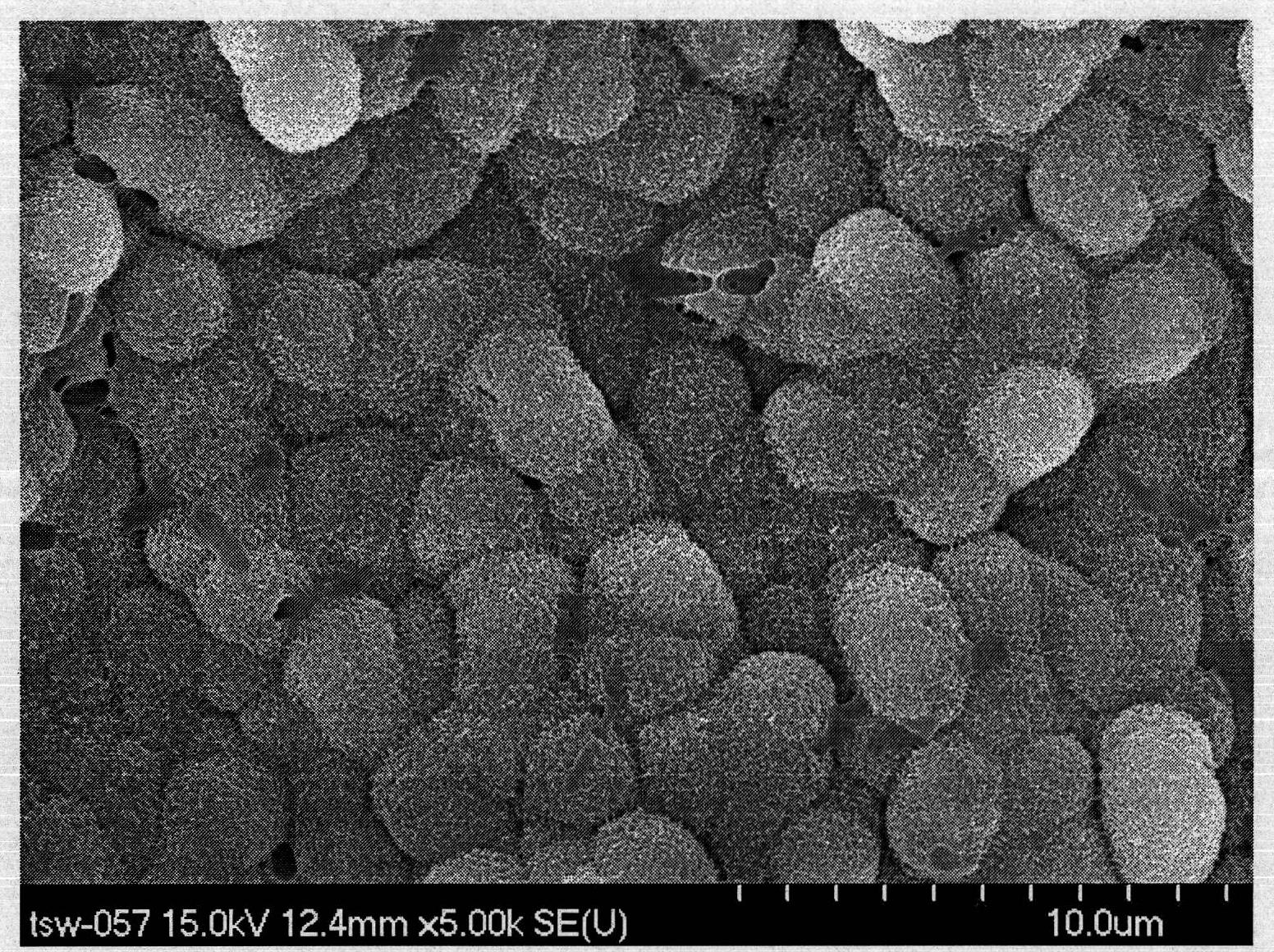

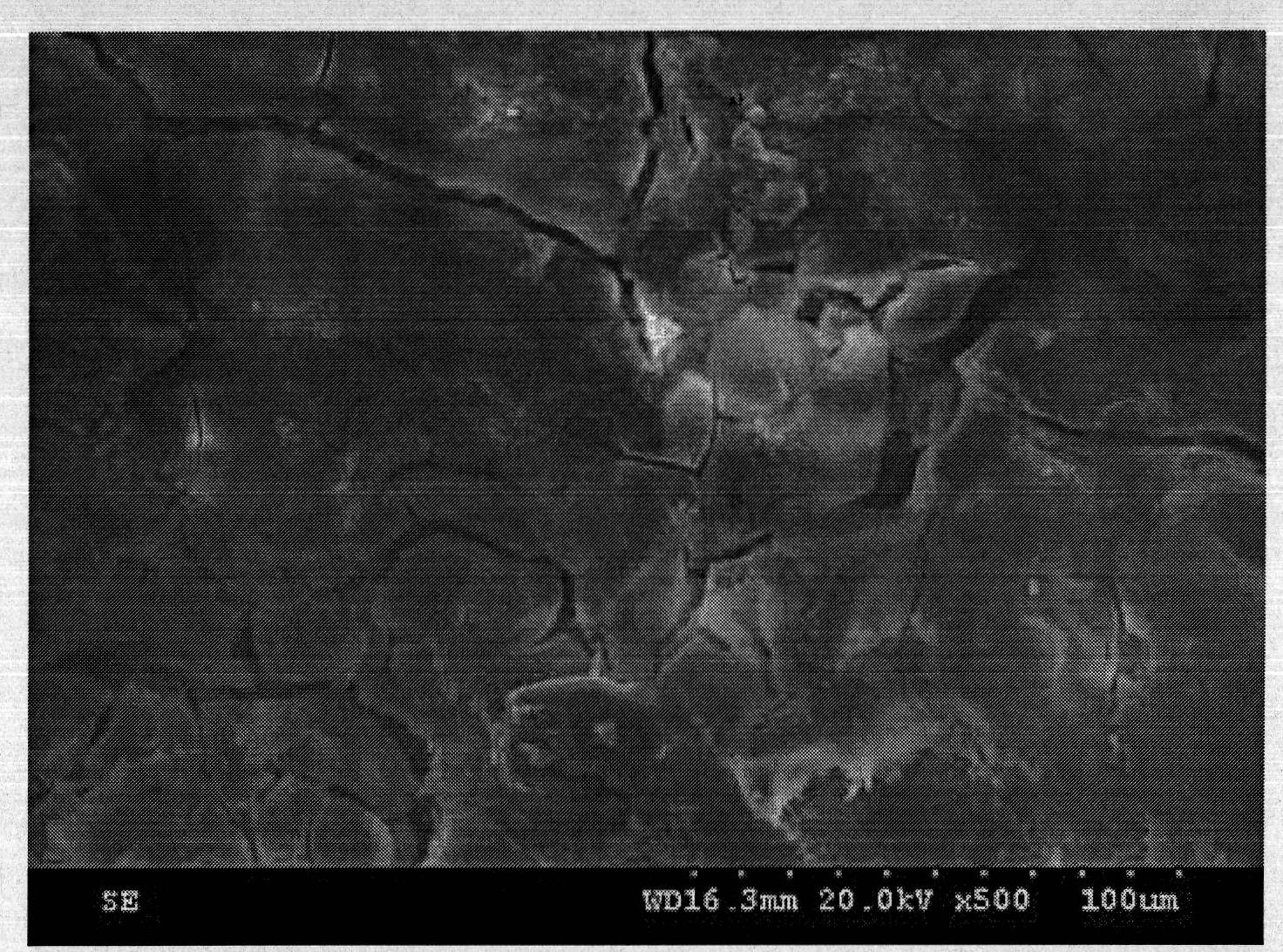

[0008] Specific Embodiment 1: The treatment method for the surface of magnesium or magnesium alloy in this embodiment is carried out according to the following steps: 1. Place the base metal in acetone or absolute ethanol solution for ultrasonic cleaning for 1-10 minutes, then rinse twice with distilled water, and then dry ; 2. Place the base material treated in step 1 in a NaOH solution with a concentration of 0.05 to 5.0 mol / L and a pH value of 12 to 14 for 0.5 to 24 hours, then rinse it twice with distilled water, and then dry it; 3. The base material treated in step 2 is placed in calcium nitrate solution, and then dipotassium hydrogen phosphate is added dropwise to the solution under the conditions of pH value of 5-7 and temperature of 20-47°C, and then standing for 10min-8h , form a layer of uniform calcium hydrogen phosphate dihydrate layer on the surface of the base metal, then rinse twice with distilled water, and then dry to complete the treatment of the surface of th...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, ultrasonic cleaning is performed for 5 minutes. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0012] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that in step 2, the solution is placed in a NaOH solution with a concentration of 0.5-4.0 mol / L and a pH value of 12.5-13.5 for 3-20 hours. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

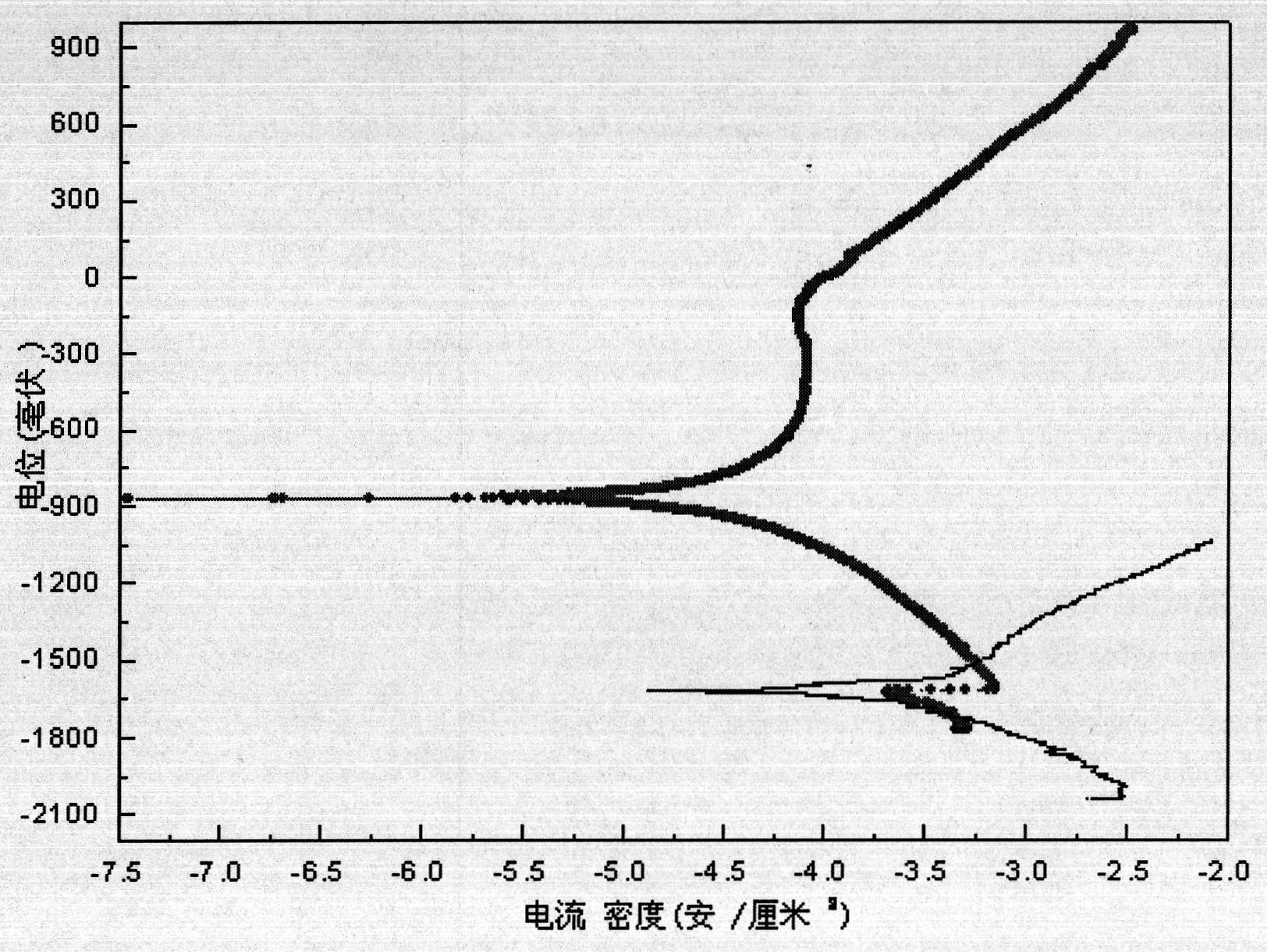

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com