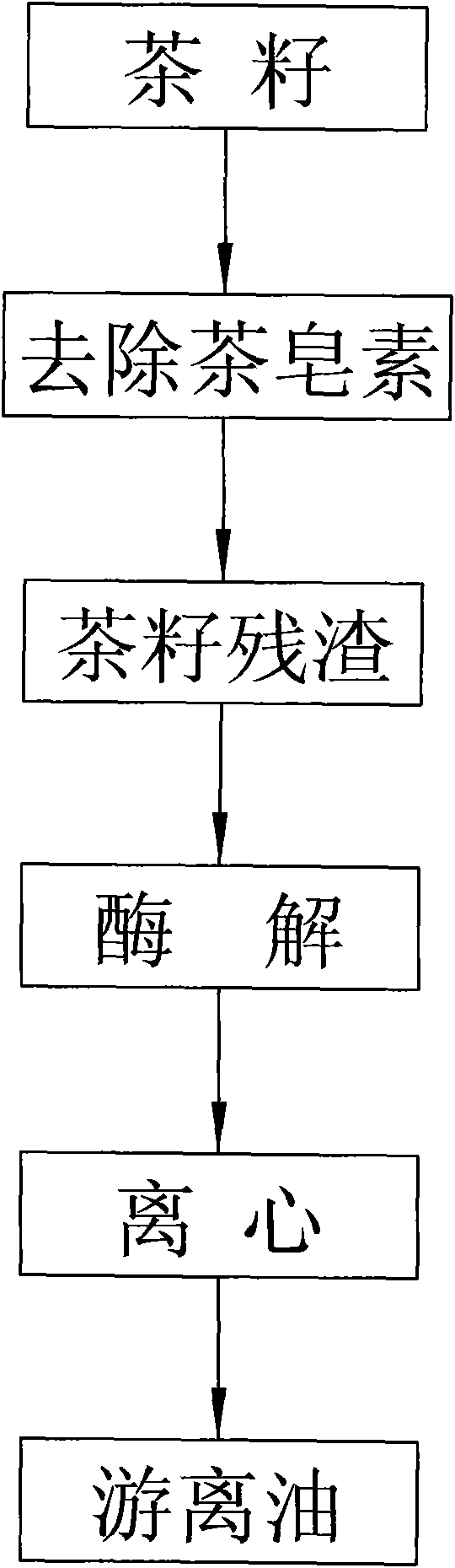

Method for extracting tea-seed oil by aqueous enzymatic method

A technology of tea seed oil and water enzymatic method, applied in edible oil/fat, food preparation, food science, etc., can solve problems such as difficult to meet safety production, easy volatilization of organic solvents, easy residual solvents, etc., and is suitable for large-scale production , No organic solvent residue, simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Embodiment: take by weighing 3 grams (wet weight) of the large fruit safflower camellia seed residue (wet weight) that removes tea saponin, 121 ℃ of high-pressure steam treatment 15 minutes, then add the disodium hydrogen phosphate-citric acid buffer solution 10ml of pH5.0, add The compound cellulase with an amount of 3.0% of the mass of Camellia oleifera seed residue was hydrolyzed at 50°C for 2 hours. After the hydrolysis, the free oil was collected by centrifugation, dried and weighed, and the free oil yield was calculated to reach 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com